Clear Anodized Aluminum Coil Stock - Aluminum Foil Alloy 8011-O Temper for Waterproofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ALUMINIUM HOUSEHOLD FOIL for roofing Alloy: 8011; Temper: O Surface finishing:; one side bright, one side matte

Specifications

1. advanced processing technology

2. accurate tolerance

3. fine craft and the best quality

ALUMINIUM HOUSEHOLD FOIL FOR ROOFING

Alloy: 8011

Temper: O

Surface finishing:; one side bright, one side matte

1.Specifications

Width range | 100~940 |

Thickness range | 0.009~0.025 |

Core materials | Aluminum or steel |

Inside diameters of core | 76.0, 152.0 |

Max. outside diameter of coil for Æ76 | 560 |

Max. outside diameter of coil for Æ, 152 | 700 |

Thickness Tolerance: +/-5%

Width Tolerance: +/-1 mm

Packaging requirements: seaworthy export standard packaging.

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

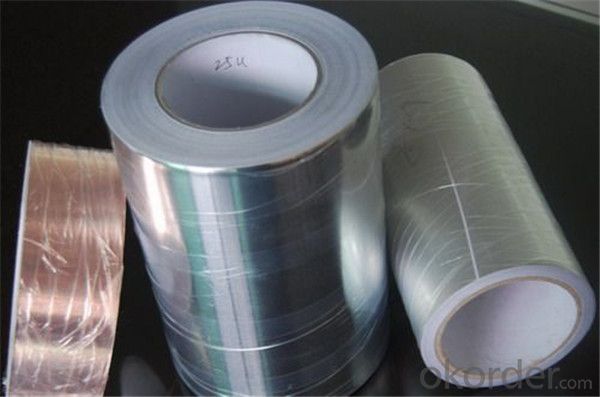

Photos

- Q: What are the different tensile strengths of aluminum coils?

- The tensile strengths of aluminum coils can vary depending on the specific alloy and manufacturing process. However, common tensile strengths for aluminum coils range from 20,000 to 70,000 pounds per square inch (psi).

- Q: What is the maximum width and thickness of aluminum coils?

- The maximum width and thickness of aluminum coils vary depending on the specific grade and manufacturing capabilities. However, as a general guideline, aluminum coils can range in width from a few inches to several feet, while thickness can range from a few millimeters to several inches. It is important to consult the manufacturer or supplier for precise specifications based on the intended application.

- Q: Is it possible to utilize a press machine to bend aluminum coils?

- <p>Yes, you can use a press to bend aluminum coils. Presses are versatile machines capable of bending various materials, including aluminum. However, it's crucial to select the appropriate press type and size for the specific coil dimensions and desired bend. Additionally, ensure the press has the necessary tonnage to handle the bending force required for aluminum. Using the right dies and lubrication can also improve the bending process and prevent damage to the coils. Always follow safety guidelines and consult with equipment specifications to ensure the press is suitable for bending aluminum.</p>

- Q: Can aluminum coils be used in automotive suspension systems?

- Yes, aluminum coils can be used in automotive suspension systems. Aluminum coils are lightweight, durable, and have excellent corrosion resistance, making them suitable for use in suspension systems. They provide better handling, improved ride quality, and enhance fuel efficiency in vehicles.

- Q: Explain the distinction between aluminum coil and copper coil, highlighting their properties and uses.

- <p>Aluminum coil and copper coil are both metal coils used in various industries, but they have distinct properties. Aluminum coil is lighter, more corrosion-resistant, and less expensive than copper coil. It is often used in applications where weight and cost are concerns, such as in construction and electrical wiring. Copper coil, on the other hand, has superior electrical conductivity and is more ductile, making it ideal for electrical applications where high conductivity is required, such as in power transmission cables and wiring for electronics. Copper is also used in plumbing due to its resistance to corrosion. In summary, the choice between aluminum and copper coil depends on the specific requirements of the application, including factors like conductivity, weight, cost, and resistance to corrosion.</p>

- Q: What are the insulation options available for aluminum coils?

- There are several insulation options available for aluminum coils, depending on the specific requirements and applications. Some common insulation options include: 1. Foam Insulation: Foam insulation is a popular choice for aluminum coils as it provides excellent thermal insulation properties. It is available in various forms, such as rigid foam boards or flexible foam sheets, and can be easily cut and fitted around the coils. 2. Fiberglass Insulation: Fiberglass insulation is another commonly used option for aluminum coil insulation. It consists of thin glass fibers that are woven together to create a blanket-like material. Fiberglass insulation is lightweight, easy to install, and offers good thermal and acoustic insulation. 3. Mineral Wool Insulation: Mineral wool insulation is made from natural or synthetic minerals, such as rock or slag, that are melted and spun into fine fibers. It is known for its excellent fire-resistance properties and provides effective thermal insulation for aluminum coils. 4. Reflective Insulation: Reflective insulation is designed to reflect radiant heat away from the aluminum coils. It typically consists of a layer of aluminum foil laminated to a layer of fiberglass or plastic bubble wrap. Reflective insulation is particularly effective in warmer climates where reducing heat gain is a priority. 5. Vapor Barrier Insulation: Vapor barrier insulation is used to prevent the transfer of moisture through the insulation material. It is often applied as a coating or film over the insulation to create a barrier against water vapor, reducing the risk of condensation buildup on the aluminum coils. It is important to consider factors such as thermal conductivity, fire resistance, moisture resistance, and installation requirements when selecting the appropriate insulation option for aluminum coils. Consulting with a professional or referring to manufacturer guidelines can help in determining the most suitable insulation option for specific coil applications.

- Q: need to know the procedure for removal of aluminum windows with brick trim

- 1st off let`s determine what kind of windows you have. Examine the inside of the jambs. Are there any screws going through the jamb into the rough opening? If so you have a masonary style window. Chances are they can be removed relatively easily. Most the time removal of fastners,scoring of drywall and caulk and they practically fall out (sometimes). You may find removal of the sash and remaining glass, then collasping the frame will work best. This technique is a must if you have the other breed of window, the flanged. You can ID this window by measuring the inside and out . If they`re the same, it`s flanged. I`ve found 99 time out of 100 these windows can be collasped. Once again remove sash and all glass. Here`s where the sawsall comes in. Remove the center bar. Drive a flat bar under the sill from the exterior. Pry it up as high as you can. Cut the sill. Now drive the flat bar between the side jambs and the brick and start prying. Most of the time these windows are only nailed on the corners, sometimes the fin will rip from the jamb. But in the end the removal will be accomplished. If you find you need to pry from the interior, don`t pry against drywall. Put a piece of wood under your bar to protect the drywall. NEVER! pry on tile or marble. I`ve removed literally thousands of these little buggers. Can`t only remember maybe a handful of times I had to cut a flange. GOOD LUCK!!!!!

- Q: What are the density and specific gravity values of aluminum coils?

- Aluminum coils have a density of around 2.7 grams per cubic centimeter (g/cm³) or 2700 kilograms per cubic meter (kg/m³). The specific gravity of aluminum coils is roughly 2.7.

- Q: What are the applications of aluminum coils?

- Aluminum coils have a wide range of applications in various industries due to their unique properties and versatility. One of the major applications of aluminum coils is in the construction industry. These coils are used for roofing, siding, and insulation purposes as they are lightweight, durable, and resistant to corrosion. Aluminum coils are also commonly used for manufacturing gutters, downspouts, and ventilation systems in buildings. In the automotive industry, aluminum coils are used for manufacturing various parts such as heat shields, radiators, and condensers. The lightweight nature of aluminum makes it an ideal choice for improving fuel efficiency and reducing the overall weight of vehicles. Additionally, aluminum coils are used in the production of heat exchangers and air conditioning systems for automobiles. Aluminum coils are extensively used in the packaging industry as well. They are commonly used for manufacturing beverage cans, food containers, and packaging materials. Aluminum's high ductility and excellent formability make it a preferred choice for producing these types of products. Moreover, aluminum coils provide a barrier against moisture, light, and oxygen, ensuring the preservation and protection of the packaged contents. Another important application of aluminum coils is in the electrical and electronics industry. These coils are used in the production of transformers, power distribution systems, and electrical conductors. Aluminum's high electrical conductivity and low density make it advantageous for these applications. Furthermore, aluminum coils find applications in the manufacturing of appliances, such as refrigerators, air conditioners, and washing machines. They are also used in the production of furniture, decorative items, and various consumer goods. Overall, the applications of aluminum coils are vast and diverse, ranging from construction and automotive industries to packaging, electrical, and consumer goods. The unique combination of lightweight, durability, corrosion resistance, and excellent formability make aluminum coils an indispensable material in numerous sectors.

- Q: Aluminum is soft, so I have a roll coating, the material is very soft, 0.7*970, into 2100, it can be processed

- The plate: cold rolled hot-rolled plate hot rolling plate, color steel plate roll roll coating color coated plateThe coating: hot galvanized coil electro galvanized coil heat tinplate tinplate chrome plate roll roll roll plastic composite steel plate other coated steel tinplate volume

Send your message to us

Clear Anodized Aluminum Coil Stock - Aluminum Foil Alloy 8011-O Temper for Waterproofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords