Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

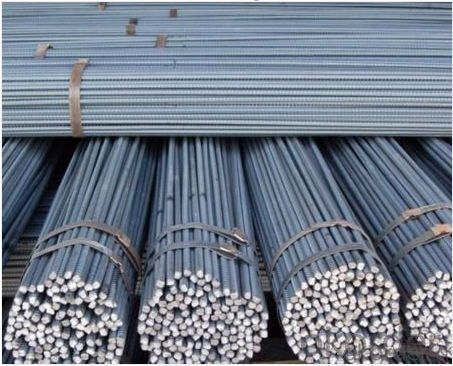

OKorder is offering Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Specifications of Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy:

Standard | GB | HRB335, HRB400, HRB500 | |

UK | G460B, B500A, B500B,B500C | ||

USA | GR40, GR60 | ||

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Place of origin | China mainland | ||

Application | building,construction,road,bridge etc | ||

Brand name | DRAGON | ||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) |

6 | 28.27 | 0.222 |

8 | 50.27 | 0.395 |

10 | 78.54 | 0.617 |

12 | 113.1 | 0.888 |

14 | 153.9 | 1.21 |

16 | 201.1 | 1.58 |

18 | 254.5 | 2.00 |

20 | 314.2 | 2.47 |

22 | 380.1 | 2.98 |

25 | 490.9 | 3.85 |

28 | 615.8 | 4.83 |

32 | 804.2 | 6.31 |

36 | 1018 | 7.99 |

40 | 1257 | 9.87 |

50 | 1964 | 15.42 |

Usage and Applications of Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

Deformed Steel Bar in Coil

Produce Line of Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Can steel rebars be used in railway and transportation infrastructure?

- Railway and transportation infrastructure can utilize steel rebars, also known as reinforcing bars, to provide strength and support to concrete structures. These rebars are widely used in the construction industry to reinforce elements such as bridge piers, abutments, and retaining walls. The inclusion of steel rebars in railway and transportation infrastructure offers numerous benefits. Firstly, they increase the tensile strength of concrete, making structures more resistant to the dynamic and heavy loads imposed by trains and vehicles, particularly in bridges and elevated structures. Secondly, steel rebars ensure structural integrity and prevent the development of cracks and deformations in the concrete. This is vital for the long-term stability and safety of the infrastructure, considering the constant exposure to varying environmental conditions like temperature fluctuations and vibrations. Moreover, steel rebars exhibit high durability and corrosion resistance, which is crucial for railway and transportation infrastructure subjected to harsh weather conditions and chemical agents. Their ability to withstand these factors guarantees the longevity of the structures and minimizes the need for frequent repairs and maintenance. In conclusion, due to their ability to enhance the strength, durability, and stability of concrete structures, steel rebars are widely used in railway and transportation infrastructure. Their incorporation ensures the safe and reliable operation of these essential transportation systems, providing a solid foundation for the efficient movement of people and goods.

- Q: Can steel rebars be used in high-strength concrete?

- Yes, steel rebars can be used in high-strength concrete. In fact, steel rebars are commonly used to reinforce concrete structures, regardless of the concrete strength. High-strength concrete refers to concrete that has a compressive strength significantly higher than conventional concrete. It typically has a compressive strength of 6,000 psi (pounds per square inch) or more. Steel rebars are essential in high-strength concrete to provide the necessary tensile strength. While concrete has excellent compressive strength, it is relatively weak in tension. By incorporating steel rebars into the concrete, the composite material becomes stronger and more durable. The rebars act as reinforcement, resisting the tensile forces and preventing cracks or failure in the structure. However, it is important to note that the selection of the appropriate steel rebar for high-strength concrete is crucial. The rebars used should have sufficient strength and ductility to withstand the higher stresses and strains associated with high-strength concrete. Additionally, proper placement, spacing, and anchorage of the rebars are essential to ensure effective reinforcement and optimal performance of the concrete structure. In summary, steel rebars can definitely be used in high-strength concrete to enhance its tensile strength and overall structural integrity.

- Q: What is the impact of steel rebars on the overall acoustic performance of a structure?

- Steel rebars have a minimal impact on the overall acoustic performance of a structure. While they may transmit some vibration and sound, their presence is generally overshadowed by other elements such as walls, floors, and ceilings. Additionally, the use of proper insulation materials and construction techniques can effectively mitigate any potential acoustic disturbances caused by steel rebars.

- Q: What is the minimum ductility requirement for steel rebars?

- The minimum ductility requirement for steel rebars is typically specified as a minimum elongation or reduction in area value, which is commonly set at 14% or 35%, respectively.

- Q: What is the difference between three - grade steel and other grades?

- 1, different grades of steel (chemical composition is different). HRB335 grade steel is 20MnSi (20 manganese silicon); HRB400 grade steel bars are 20MnSiV or 20MnSiNb or 20MnTi etc.;2, strength is different, HRB335 grade steel tensile and compressive design strength is 300MPa, HRB400 grade steel tensile and compressive design strength is 360MPa.

- Q: Are there any specific guidelines for storing and handling steel rebars?

- Yes, there are specific guidelines for storing and handling steel rebars. Here are some important points to consider: 1. Storage: Steel rebars should be stored in a clean, dry, and well-ventilated area to prevent corrosion. They should be stacked on timber or other suitable materials to keep them off the ground and avoid contact with moisture. 2. Handling: Steel rebars should be handled with care to prevent any damage or bending. It is recommended to use appropriate equipment such as cranes, forklifts, or strong hooks to lift and move rebars. Avoid dragging or dropping them, as it can result in deformations and weaken their structural integrity. 3. Bundling: Rebars should be properly bundled and tied together using steel wires or straps to prevent them from rolling or shifting during storage or transportation. This ensures their stability and reduces the risk of accidents. 4. Separation: Different sizes and types of rebars should be separated and clearly labeled to avoid confusion during construction. This helps in easily identifying and using the required rebar as per the structural plans. 5. Protection: Rebars should be protected from exposure to moisture, rain, snow, and other weather elements. If rebars are stored outdoors, waterproof covers or tarps should be used to shield them and prevent rust formation. 6. Inspection: Regular inspections should be conducted to identify any signs of corrosion, damage, or bending. Any defective or compromised rebars should be removed and replaced to ensure the structural integrity of the construction project. 7. Transportation: During transportation, rebars should be securely fastened and loaded onto suitable vehicles to prevent movement or falling off. Adequate padding and tie-downs should be used to protect rebars from damage and ensure safe transportation. It is crucial to follow these guidelines to maintain the quality, durability, and safety of steel rebars throughout their storage and handling process.

- Q: How do steel rebars affect the structural integrity of a building?

- Steel rebars play a crucial role in enhancing the structural integrity of a building. They are used to reinforce concrete structures by providing extra strength and resistance to various forces, such as tension, compression, and bending. The inclusion of steel rebars helps to distribute loads more evenly, prevent cracks, and increase the overall durability and stability of the building.

- Q: What is the process of reinforcing existing concrete structures with steel rebars?

- The process of reinforcing existing concrete structures with steel rebars involves several steps. First, a structural assessment is conducted to determine the areas that require reinforcement. Once identified, the concrete surface is prepared by cleaning and removing any loose or deteriorated material. Next, the rebars are positioned and secured to the existing concrete using epoxy adhesive or mechanical anchors. These rebars are strategically placed to distribute and support the additional load. Finally, the rebars are encased in a new layer of concrete called shotcrete or sprayed concrete, which acts as a protective and bonding layer. The result is a strengthened and more durable concrete structure capable of withstanding increased loads and extending its lifespan.

- Q: Can steel rebars be used in industrial structures?

- Yes, steel rebars can be used in industrial structures. They are commonly used for reinforcing concrete in various industrial constructions such as bridges, buildings, and infrastructure projects. Steel rebars provide strength, durability, and resistance to structural loads, making them suitable for use in industrial settings.

- Q: What are the different sizes of steel rebars available?

- The different sizes of steel rebars available typically range from #3 (3/8 inch diameter) to #18 (2 1/4 inch diameter), with various lengths and shapes also being offered.

Send your message to us

Chrome Deformed Steel Bar with Prime Newly Produced Hot Rolled Alloy

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords