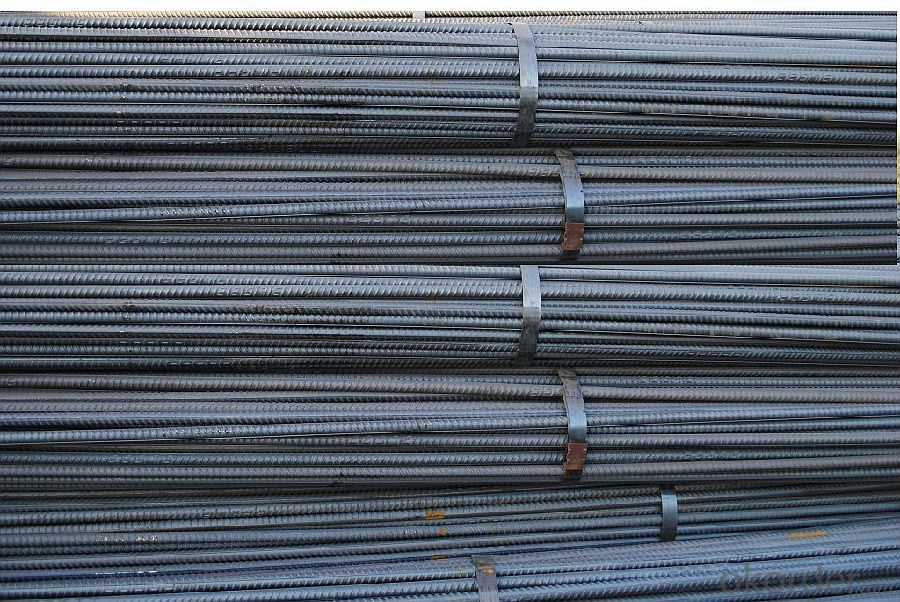

36mm*1018kg/m deformed steel bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering 36mm*1018kg/m deformed steel bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

36mm*1018kg/m deformed steel bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's deformed steel bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Standard:AISI, ASTM, GB

Grade:HRB335

Diameter:6mm-15mm

Length:9m

Place of Origin:Hebei, China (Mainland)

Brand Name:mammoth

Model Number:HRB335 HRB400 HRB400E G60 GR460

Application:construction of houses

color:black

Standard:AISI,ASTM,BS,DIN,GB,JIS

Grade:HRB335

Diameter:6mm-15mm

Length:9m

Place of Origin:Hebei, China (Mainland)

Brand Name:mammoth

Model Number:6mm

Application:construction of houses, bridges, roads and other civil works,making Concrete

<:article class="article detailDescription richTextDescription AE:disable" id=richTextContainer sizset="2" sizcache01431106158450841="5">

1)Material: HRB335,HRB400,HRB400E,G60,GR460

2)FOB price: $560-610

3)Payment terms: TT or LC

4)MOQ: 50MT

Deformed Reinforcement Steel Bar

1)Grade: GB1499.2-2007, BS4449 A615

2) Diameter: 6,8,10,12,14,16,18,20,22,25,28,32mm

3)Application: making Concrete , construction of houses, bridges, roads and other civil works. It's also the material to make the reinforcing mesh-a new type of construction material, particularly suitable for large areaconcreteengineering.

We are manufacture specilized in Steel Wire and Rebar with 8 years' experience. Our mill is near the seaport, with low logistic cost . Every month we export 5000mt goods to other countries, and have gained the widly reputation from our customers .

FAQ:

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Are there any standards or codes governing the use of steel rebars in construction?

- Yes, there are several standards and codes that govern the use of steel rebars in construction. For example, the most widely recognized standard is the ASTM A615/A615M, which outlines the requirements for deformed carbon-steel bars for concrete reinforcement. Additionally, various building codes such as the International Building Code (IBC) and local building regulations often reference these standards to ensure the safe and proper use of steel rebars in construction projects.

- Q: Can steel rebars be used in retrofitting existing structures?

- Yes, steel rebars can be used in retrofitting existing structures. Retrofitting is the process of strengthening or upgrading existing buildings or structures to make them more resistant to various forces or to meet new design requirements. Steel rebars are commonly used in retrofitting as they provide increased structural strength and stability when properly installed and reinforced within existing structures.

- Q: What are the guidelines for the proper installation of steel rebars?

- Achieving the structural integrity and durability of reinforced concrete structures relies heavily on the correct installation of steel rebars. To ensure their proper installation, the following guidelines must be followed: 1. Planning and Design: Prior to commencing installation, a detailed plan and design must be established. This involves determining the necessary rebar size, spacing, and configuration based on structural requirements and specifications. It is crucial to consult with structural engineers and adhere to local building codes and regulations. 2. Cutting and Bending: Rebars should be accurately cut and bent in accordance with the design specifications. The use of appropriate tools, such as rebar cutters and benders, is necessary to achieve clean cuts and precise bends. Any rebars that are damaged or corroded should be discarded and replaced. 3. Cleaning and Preparation: The surface of the rebars should be free from contaminants such as rust, oil, dirt, or loose scales before installation. The recommended method for cleaning rebars is using wire brushes or air blasting to ensure proper adhesion between the rebar and concrete. 4. Placement and Positioning: Rebars should be placed and positioned accurately based on the design drawings. They should be securely tied or supported using tie wires or rebar chairs to maintain the desired spacing and alignment. Splices should be made according to the design requirements and properly lapped to ensure continuity and strength. 5. Concrete Cover: Adequate concrete cover is crucial to protect the rebars from corrosion and provide fire resistance. The concrete cover thickness should meet the design specifications and local building codes. Proper spacing between rebars and formwork should be maintained to allow for proper concrete flow and consolidation. 6. Anchorage and Embedment: Sufficient anchorage and embedment of rebars are essential for load transfer and structural stability. Special attention should be given to providing proper hooks, bends, or mechanical anchorage at the ends of rebars as required by the design. The rebars should be appropriately embedded into adjacent concrete elements to achieve the desired bond strength. 7. Inspection and Quality Control: Regular inspection should be conducted throughout the installation process to ensure compliance with design specifications and quality standards. Any deviations or defects should be promptly identified and rectified. It is important to document the installation process and maintain proper records for future reference. By adhering to these guidelines, the proper installation of steel rebars can be accomplished, guaranteeing the structural strength, longevity, and safety of reinforced concrete structures.

- Q: Can steel rebars be used in architectural concrete elements?

- Indeed, architectural concrete elements can incorporate steel rebars for reinforcement, thereby augmenting the strength and longevity of the structure. It is customary to employ steel rebars in concrete construction as they fortify the concrete and enhance its durability. In the realm of architectural concrete, rebars can be tactically positioned to fortify the structural integrity of the elements, while simultaneously contributing to their visual appeal. Depending on the desired design outcome, these rebars can either be visibly exposed or discreetly concealed within the concrete. By utilizing steel rebars, architects possess the versatility to fashion intricate and distinctive architectural elements, all the while ensuring the requisite strength and stability.

- Q: What are the advantages of using composite steel rebars?

- There are several advantages of using composite steel rebars. Firstly, composite steel rebars offer higher tensile strength compared to traditional steel rebars, making them more durable and resistant to deformation. Secondly, they have a lower coefficient of thermal expansion, reducing the risk of cracking and improving long-term performance. Additionally, composite steel rebars are corrosion-resistant, ensuring a longer lifespan and lower maintenance costs. Furthermore, these rebars are lighter in weight, making them easier to handle and transport. Lastly, composite steel rebars can be easily fabricated and installed, allowing for greater design flexibility and faster construction.

- Q: How do steel rebars affect the thermal conductivity of concrete structures?

- Steel rebars have a significant impact on the thermal conductivity of concrete structures. The inclusion of steel rebars in concrete increases the overall thermal conductivity of the structure. This is because steel has a much higher thermal conductivity than concrete. Consequently, heat transfer through the concrete is facilitated by the presence of steel rebars, leading to a higher overall thermal conductivity of the structure.

- Q: How do steel rebars help in load distribution within a structure?

- Steel rebars, also known as reinforcing bars, play a crucial role in load distribution within a structure. They are extensively used in concrete structures, such as buildings, bridges, and highways, to enhance their strength and durability. The primary purpose of steel rebars is to provide tensile strength to the concrete. While concrete is excellent in compression, it is relatively weak in tension. Any structure subjected to loads, whether from the weight of the building itself or external forces, will experience both compression and tension forces. By placing steel rebars within the concrete, they act as reinforcement and resist tensile forces. When an external load is applied to the structure, the rebars carry a significant portion of the tension forces generated. This prevents the concrete from cracking or failing under the applied load. Moreover, steel rebars help in distributing the load throughout the structure. When a load is applied to a structure, it creates stress that is distributed across the various components. The presence of rebars allows for a more even distribution of these stresses, reducing the concentration of forces in specific areas. This prevents localized failures and ensures that the load is evenly dispersed across the structure, improving its overall strength and stability. Another important aspect of steel rebars is their ability to bond with concrete. The rough surface of the rebars prevents them from slipping or separating from the concrete, ensuring a strong bond between the two materials. This bond further enhances the load distribution by allowing the rebars to effectively transfer the tensile forces to the surrounding concrete. In summary, steel rebars play a vital role in load distribution within a structure. They provide the necessary tensile strength to resist tension forces, distribute the load evenly across the structure, and bond with the concrete, ensuring a robust and stable construction. Without steel rebars, concrete structures would be significantly weaker and more susceptible to cracking or failure under load.

- Q: What are the common defects found in steel rebars?

- Some common defects found in steel rebars include surface cracks, improper dimensions, bending or twisting, rust or corrosion, and inadequate strength due to poor quality control during manufacturing or handling processes.

- Q: Can steel rebars be used in tunnel lining construction?

- Yes, steel rebars can be used in tunnel lining construction. Rebars provide reinforcement and strength to the concrete used in tunnel lining, making it more durable and resistant to structural stresses.

- Q: What is the thermal expansion coefficient of steel rebars?

- The thermal expansion coefficient of steel rebars refers to the rate at which the rebars expand or contract with changes in temperature. Steel is known to have a relatively low thermal expansion coefficient, typically around 12 x 10^-6 per degree Celsius. This means that for every degree increase in temperature, the length of the steel rebar will increase by approximately 0.000012 times its original length. It is important to consider the thermal expansion coefficient of steel rebars in construction projects to prevent potential issues such as structural instability and cracking due to temperature variations.

Send your message to us

36mm*1018kg/m deformed steel bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords