Chopped Strands for BMC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Chopped Strands for BMC

Chopped Strands for BMC are compatible with unsaturated polyester, epoxy resin and phenolic resins.

The end-use applications include transportation, building & construction, electronic & electrical, mechanical, and light industry

Features of Chopped Strands for BMC

Low viscosity and excellent flowability of the BMC paste

Low static and low fuzz, fast and good dispersion in resins

Good processing and excellent mechnical properties

Specification of Chopped Strands for BMC

Product No. | Nominal Chopped Length(mm) | Product Features | Resin Compatibility | Applications |

562A | 3,6,9,12 | Extremely low resin demand, delivering low viscosity to BMC paste | Unsaturated polyester, vinyl ester and epoxy resins | Suitable to manufacture high fiberglass loading products with complex structure and superior color, for example, ceiling tiles and lampshade. |

552B | 3,6,9,12 | High impact strength; High LOI rate | Unsaturated polyester, vinyl ester and epoxy resins | Used in automotive parts, civilian electrical switches, sanitary ware and other products requiring high strength. |

558 | 3,6,9,12 | Good strand integrity, low static and fuzz, Fast and uniform distribution in resins, excellent mechanical and processing properties | Rubber and Phenolic resin | Used to manufacture various brake shoe facings, clutch facings, and friction plates. |

Storage of Chopped Strands for BMC

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15 Deg.C-35 Deg.C and 35%-65% respectively.

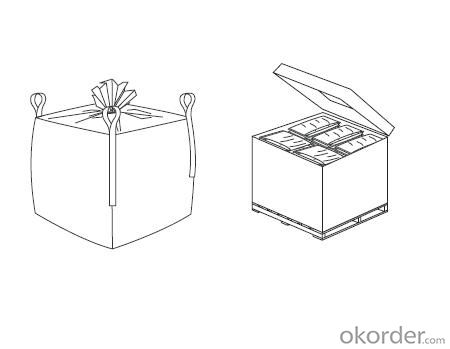

Photo of Chopped Strands for BMC

- Q: What is glass fibre reinforced plastic

- It can pass through the electromagnetic wave. It is made of synthetic resin and glass fiber through the composite process with good electrical insulation, high strength, and easy coloring. Glass fiber reinforced plastic is a new functional composite material used in different field with light weight, good instantaneous high temperature performance and thermal insulation. Glass?reinforced?plastics has a wide variety with slow heat transfer(also known as glass fiber reinforced plastic, internationally recognized abbreviation is GFRP or FRP).

- Q: The safe operation of glass fiber twisting frame

- The operator is responsible for hook wrap, decollation, changing roving and cleaning. Doffer is responsible for cleaning. Both of them needs skills.

- Q: An introduction to glass fiber cloth

- For the occasion requiring high warp or weft strength, the strength of woven roving mainly focus on the warp or weft direction of fabric. Roving roving is composed of parallel raw silk or parallel filaments. According to glass composition, twistless roving can be divided into unidirectional cloth E-GLASS alkali-free glass twistless roving and C-GLASS medium alkali glass twistless roving. Glass fiber woven roving is twistless roving plain fabric and is an important base material for pasting glass?reinforced?plastics. Moreover, it is also unidirectional weft cloth.

- Q: What are the advantages of the glass?reinforced?plastics antenna? What is the difference between an ordinary antenna and a glass?reinforced?plastics antenna?

- High gain

- Q: An introduction to glass fiber geogrid

- It is net?structure material woven through a certain method. In order to protect the glass fiber and improve the overall performance, it is geotechnical base material with excellent performance formed by a special coating treatment process. Glass fiber alkali free twistless roving is the main material of glass fiber geogrid.

- Q: What parts must used fiber reinforced concrete?

- Aircraft runway.

- Q: Nominal interpretation of fiber reinforced concrete

- Mix composite materials with random and uniform distribution of short fiber in cement concrete, including steel fiber reinforced concrete. Technical specification for fiber reinforced concrete structures CECS.

- Q: What is the material of glass steel? How to make it?

- We mainly use glass fiber, and the adhesive is composed of unsaturated resin; curing agent, cyclohexanone; peroxide initiator, cobalt naphthenate (also used for the curing agent of benzoyl peroxide, initiator amine). The rate of solidation changes sharply with temperature, humidity and the curing to recipe. Roughly 100: 4: 1. There are processing winding machine to wind liner (tank shape) in axial and circumferential direction, soak it with adhesives before winding. According to the different liner, it is divided into two categories: Glass steel liner glass cloth paste and polyethylene liner polyethylene rotational molding.

- Q: How to produce 0.3 mm glass fiber Chopped strand? What kind of glass fiber yarn is better?

- with strong ability in grinding). And when producing the asbestos shingle, there should be a progress of mixing the materials. The short fibercan be morceled by chopping machine or manually. The reason for short fiberis is avoid all fiber winding and fiber grinding (the main component of glass fiber is silica, and offal of glass fiber used for asbestos shingle. It is low cost, and do not need any special requirements. For the current market.

Send your message to us

Chopped Strands for BMC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords