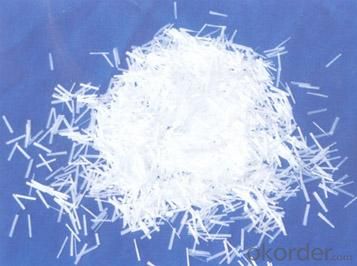

Owens Corning Chopped Strand Fiberglass for BMC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Chopped Strands for BMC are compatible with unsaturated polyester, epoxy resin and phenolic resins.

The end-use applications include transportation, building & construction, electronic & electrical, mechanical, and light industry.

2.Product Features

Extremely low resin demand, delivering low viscosity to BMC paste

High impact strength; High LOI rate

High strand stiffness; Compatible with rubber

3.Product Specifications

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: What is the typical length of fiberglass chopped strand?

- The typical length of fiberglass chopped strand can vary depending on the specific application or industry it is being used in. However, the most commonly used lengths range from 1/8 inch (3 mm) to 1 inch (25 mm).

- Q: What types of resins can be used with fiberglass chopped strand?

- There are several types of resins that can be used with fiberglass chopped strand. The most commonly used resins include polyester resin, epoxy resin, and vinyl ester resin. Polyester resin is the most widely used resin for fiberglass applications due to its low cost and ease of use. It is suitable for a variety of applications including boats, automotive parts, and construction materials. Epoxy resin is known for its superior strength and excellent adhesion to various substrates, making it ideal for high-performance applications such as aerospace and marine industries. Vinyl ester resin is a hybrid between polyester and epoxy resins, offering improved corrosion resistance and toughness. It is often used in applications that require enhanced durability and chemical resistance, such as chemical storage tanks and pipes. Ultimately, the choice of resin depends on the specific requirements of the application, such as strength, durability, and chemical resistance.

- Q: What are the weathering resistance properties of fiberglass chopped strand?

- The weathering resistance properties of fiberglass chopped strand are generally quite good. Fiberglass is known for its durability and ability to withstand various environmental conditions. It is resistant to UV radiation, moisture, and temperature fluctuations. This makes it highly suitable for outdoor applications where exposure to sunlight and weather elements is common. Fiberglass chopped strand can maintain its structural integrity and aesthetic appeal even when exposed to harsh weather conditions such as intense sunlight, rain, wind, and extreme temperatures. It does not degrade or deteriorate easily, making it a reliable material for long-term use. The resin used to bind the fiberglass strands together also plays a crucial role in enhancing its weathering resistance properties. Advanced resin formulations can provide additional protection against UV radiation and other environmental factors, further improving its resistance to weathering. However, it is important to note that the specific weathering resistance properties of fiberglass chopped strand can vary depending on various factors such as the quality of the material, manufacturing process, and specific environmental conditions it is exposed to. Therefore, it is recommended to consult the manufacturer or supplier for detailed information on the weathering resistance properties of a specific fiberglass chopped strand product.

- Q: What are the typical surface preparation techniques for fiberglass chopped strand composites?

- Typically, the surface preparation techniques for fiberglass chopped strand composites involve a series of steps to ensure proper bonding and adhesion of the composite material. The first step in surface preparation is cleaning the surface of the composite. This is done to remove any dirt, dust, oils, or other contaminants that may be present. Cleaning can be done using solvents or detergents, followed by rinsing and drying the surface thoroughly. After cleaning, the next step is abrasion or roughening of the surface. This is typically done using sandpaper, abrasive pads, or a sanding machine. Abrasion helps create a rough surface profile, which improves the mechanical interlocking between the composite material and the substrate. Once the surface is roughened, it is important to remove any dust or debris generated during the abrasion process. This can be done by blowing compressed air or vacuuming the surface. The next step is applying a suitable primer or surface treatment. The choice of primer or treatment depends on the specific requirements and compatibility with the composite material. Primers help enhance adhesion and provide a barrier against moisture or other environmental factors. They can be applied using brushes, rollers, or spray equipment. After the primer or treatment is applied, it is allowed to dry or cure as per the manufacturer's instructions. This ensures that the surface is ready for the final step, which is the application of the chopped strand composite. It is important to note that the specific surface preparation techniques may vary depending on the type of fiberglass chopped strand composite and the intended application. Manufacturers or suppliers of the composite material usually provide detailed instructions and guidelines for surface preparation, which should be followed for optimal results.

- Q: How does the fiber content affect the mechanical properties of fiberglass chopped strand composites?

- The mechanical properties of fiberglass chopped strand composites are significantly influenced by the amount of fiber present. Firstly, the overall strength and stiffness of the composite material are determined by the fiber content. Increasing the fiber content enhances the strength and stiffness as the fibers reinforce the material. These fibers act as load-bearing elements, distributing stress and preventing cracks, leading to improved tensile, flexural, and compressive strength. Secondly, the impact resistance of the composites is affected by the fiber content. A higher fiber content increases the material's ability to absorb energy, making it more resistant to impacts. The fibers act as barriers, absorbing and dispersing impact energy, minimizing damage and crack formation. Moreover, the fiber content also has an impact on the thermal properties of the composites. Fiberglass fibers have low thermal conductivity, meaning they are not good conductors of heat. By increasing the fiber content, the composites become more resistant to heat flow, making them suitable for applications requiring thermal insulation. Additionally, the dimensional stability of the composites is influenced by the fiber content. Higher fiber content reduces the coefficient of thermal expansion, making the material less prone to expansion and contraction caused by temperature changes. This characteristic is particularly important in industries like aerospace and automotive, where dimensional stability is crucial. To summarize, the fiber content in fiberglass chopped strand composites plays a crucial role in determining their mechanical properties. Higher fiber content improves strength, stiffness, impact resistance, thermal insulation, and dimensional stability. It is essential to understand and optimize the fiber content in order to design and manufacture composites that meet specific performance requirements.

- Q: How does the fiber volume fraction affect the performance of fiberglass chopped strand?

- The percentage of fibers present in a composite material is known as the fiber volume fraction. When it comes to fiberglass chopped strand, boosting the fiber volume fraction directly affects its performance. Raising the fiber volume fraction results in enhanced mechanical properties for fiberglass chopped strand. This is because the fibers are the main load-bearing element of the composite material. As the volume fraction of fibers increases, the material becomes stronger, more rigid, and more resistant to deformation. Consequently, fiberglass chopped strand with a higher fiber volume fraction can withstand greater loads and display improved durability and dimensional stability. Moreover, a higher fiber volume fraction improves the bonding between the fibers and the matrix material in the composite. This leads to better transfer of loads between the fibers and the matrix, resulting in increased energy absorption and resistance to cracks or fractures. The improved bonding also enhances the overall toughness of the fiberglass chopped strand, making it more capable of withstanding impact and fatigue. Nevertheless, there is a limit to the advantages of increasing the fiber volume fraction. Once the critical fiber volume fraction is reached, the performance gains become less significant. This is primarily because achieving a uniform distribution of fibers becomes challenging at very high volume fractions, which increases the likelihood of defects like voids or clustering. These defects can weaken the material and diminish its overall performance. In conclusion, the fiber volume fraction significantly affects the performance of fiberglass chopped strand. Elevating the fiber volume fraction enhances the material's mechanical properties, bonding, and overall toughness. However, it is crucial to ensure a uniform distribution of fibers to prevent detrimental defects.

- Q: Is fiberglass chopped strand suitable for the production of roofing materials?

- Indeed, fiberglass chopped strand is well-suited for manufacturing roofing materials. As a reinforcement material, fiberglass chopped strand finds widespread application in the production of diverse products, including roofing materials. It boasts exceptional strength and durability, rendering it highly suitable for enduring the harsh weather conditions that roofs encounter. Moreover, its lightweight nature lessens the burden on the roof structure. In addition, it exhibits resistance to corrosion and possesses commendable thermal insulation characteristics. These attributes render it an apt selection for manufacturing roofing materials, guaranteeing roofs that are both enduring and dependable.

- Q: Is fiberglass chopped strand suitable for applications requiring high impact resistance?

- Fiberglass chopped strand is unsuitable for applications that demand high impact resistance. Despite its renowned strength and durability, it lacks the essential properties to withstand significant impacts. Typically, it is employed in scenarios where strength and stiffness take precedence, such as automotive parts, boats, and construction materials. For applications necessitating high impact resistance, alternative materials like carbon fiber or Kevlar prove more suitable. These materials possess superior impact resistance properties and are commonly utilized in industries like aerospace, sports equipment, and personal protective equipment.

- Q: What are the typical flexural strength values of chopped strand composites?

- The typical flexural strength values of chopped strand composites can vary depending on several factors such as the type of resin matrix, fiber content, fiber orientation, and manufacturing process. However, in general, chopped strand composites exhibit flexural strength values ranging from 100 MPa to 400 MPa (14,500 psi to 58,000 psi). The flexural strength of a chopped strand composite refers to its ability to resist bending or deformation under a load. This property is crucial in applications where the material is subjected to bending or flexing forces, such as in structural components or automotive parts. The specific flexural strength values can be influenced by the type of fibers used, such as glass, carbon, or natural fibers. Glass fibers are commonly used in chopped strand composites and typically provide a flexural strength ranging from 100 MPa to 200 MPa (14,500 psi to 29,000 psi). Carbon fibers, on the other hand, offer higher flexural strength values, typically ranging from 200 MPa to 400 MPa (29,000 psi to 58,000 psi), making them suitable for applications that require high strength and stiffness. It is important to note that the actual flexural strength values of chopped strand composites can vary significantly based on the aforementioned factors and manufacturing techniques. Therefore, it is recommended to consult specific material datasheets or conduct testing to determine the precise flexural strength values for a particular chopped strand composite.

- Q: How does fiberglass chopped strand compare to other reinforcing fibers?

- Fiberglass chopped strand is a type of reinforcing fiber that is commonly used in various industries for its exceptional strength and durability properties. When compared to other reinforcing fibers such as carbon fiber, aramid fiber, and natural fibers, fiberglass chopped strand offers several unique advantages. Firstly, fiberglass chopped strand is known for its high tensile strength, which is comparable to carbon fiber. This makes it an excellent choice for applications that require lightweight yet strong materials, such as automotive and aerospace industries. Additionally, fiberglass chopped strand has a relatively low cost compared to carbon fiber, making it a cost-effective alternative for many applications. Another advantage of fiberglass chopped strand is its excellent chemical resistance. It is highly resistant to corrosion, moisture, and most chemicals, making it suitable for use in harsh environments. In contrast, natural fibers such as cotton or jute are more susceptible to degradation when exposed to chemicals or moisture. Furthermore, fiberglass chopped strand is highly versatile and can be easily molded into different shapes and sizes. This allows for greater design flexibility and customization possibilities. Carbon fiber, on the other hand, is more rigid and difficult to shape, limiting its application in some scenarios. However, it is important to note that fiberglass chopped strand does have some limitations. It is not as stiff as carbon fiber, meaning it may not provide the same level of rigidity and stiffness in certain applications. Additionally, fiberglass is a relatively brittle material, making it prone to cracking or breaking under high impact or stress. In contrast, aramid fibers, such as Kevlar, have higher impact resistance. In summary, fiberglass chopped strand is a highly effective reinforcing fiber that offers a combination of strength, durability, chemical resistance, and cost-effectiveness. While it may not possess the same level of stiffness as carbon fiber or impact resistance as aramid fibers, it remains a popular choice in many industries due to its versatility and excellent performance in a wide range of applications.

Send your message to us

Owens Corning Chopped Strand Fiberglass for BMC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords