Chocolate Brown Aluminum Coil - Aluminium Prepainted PVDF with 10μ 1100 H18

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Prepainted PVDF with 10μ 1100 H18 Description:

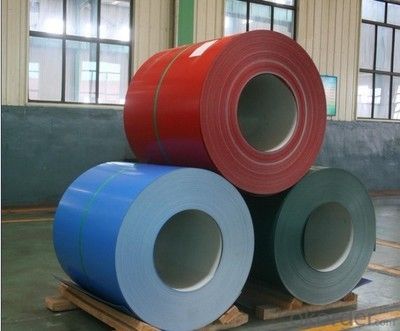

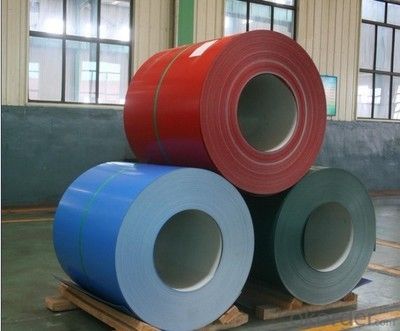

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepainted PVDF with 10μ 1100 H18:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Prepainted PVDF with 10μ 1100 H18:

Aluminium Prepainted PVDF with 10μ 1100 H18 Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the potential applications of laminated aluminum coils?

- Laminated aluminum coils have a wide range of potential applications. They can be used in industries such as electrical, automotive, aerospace, and construction. Some specific applications include electrical transformers, heat exchangers, automotive radiators, air conditioning systems, and architectural facades. The lamination process enhances the durability, heat and corrosion resistance, and electrical conductivity of the coils, making them suitable for various demanding environments and applications.

- Q: What is the shear strength of aluminum coils?

- The shear strength of aluminum coils varies depending on the specific alloy and temper. However, on average, aluminum coils have a shear strength ranging from 110 MPa to 190 MPa.

- Q: Pretty please can someone show me the steps on how to do this one?Calculate the mass in grams of iodine (I2) that will react completely with 43.7 g of aluminum (Al) to form aluminum iodide

- easily the guy earlier me did it precise yet made a mistake at one ingredient 0.07 mole is the # of moles of Al which desires to get replaced to moles of product, and then returned to come across mole of iodide. as quickly as thats stumbled on then you quite can use the MW to alter it to grams.

- Q: May anyone tell me what's the product when hydrochloric acid reacts with aluminum?HCl + Al → ?

- Amonia Hydrochlorite

- Q: This question asks about the economic impact of aluminum coils, which are a key material in various industries.

- <p>Aluminum coils significantly impact the economy by driving growth in various sectors. They are vital in construction, automotive, aerospace, and packaging industries due to their lightweight, durability, and recyclability. The aluminum coil market stimulates manufacturing, job creation, and technological advancements. Additionally, their high demand supports the growth of the aluminum industry, influencing trade and contributing to GDP. The recycling of aluminum coils also reduces energy consumption and environmental impact, further benefiting the economy by promoting sustainable practices.</p>

- Q: What are the different forming processes for aluminum coils?

- Some of the different forming processes for aluminum coils include rolling, coiling, slitting, and annealing.

- Q: Are there any specific regulations or standards for aluminum coil production?

- Yes, there are specific regulations and standards for aluminum coil production. These regulations and standards are put in place to ensure the quality, safety, and sustainability of the production process. One of the most important standards for aluminum coil production is the American Society for Testing and Materials (ASTM) International standard. ASTM B209 is the standard specification for aluminum and aluminum-alloy sheet and plate, which includes the requirements for aluminum coil production. This standard specifies the chemical composition, mechanical properties, and other technical requirements that the aluminum coil must meet. In addition to ASTM standards, there are also regulations and standards set by regulatory bodies such as the International Organization for Standardization (ISO) and the Occupational Safety and Health Administration (OSHA). ISO 9001 is a widely recognized standard for quality management systems, and ISO 14001 is for environmental management systems. These standards provide guidelines and requirements for the production process to ensure quality, environmental responsibility, and worker safety. Furthermore, specific regulations may vary by country or region. For example, in the United States, the Environmental Protection Agency (EPA) regulates the emissions and waste disposal associated with aluminum coil production through the Clean Air Act and the Resource Conservation and Recovery Act (RCRA). These regulations aim to minimize the environmental impact of the production process. Overall, the regulations and standards for aluminum coil production are in place to uphold the quality, safety, and environmental sustainability of the industry. Compliance with these regulations and standards is essential for manufacturers to ensure that their products meet the required specifications and are produced in a responsible manner.

- Q: How are aluminum coils protected against scratches and damage?

- Aluminum coils can be safeguarded from scratches and damage through various methods. One effective approach involves applying a protective coating or film to the surface of the coil, serving as a barrier against potential sources of damage like abrasion or impact. Another means of protection is through the utilization of coil coating. This involves cleaning, pre-treating, and coating the coil with a layer of protective paint or resin. This not only enhances the coil's appearance but also provides a safeguard against scratches and other types of damage. Moreover, during the manufacturing and handling process, aluminum coils are frequently wrapped or packaged using materials that offer cushioning and protection. This prevents scratches or dents that may occur during transportation or storage. Lastly, proper handling and storage practices are crucial in preserving the integrity of aluminum coils. Exercising care when handling the coils, employing suitable equipment and techniques, can effectively minimize the risk of scratching or causing other damage. Storing the coils in a clean and dry environment further aids in preventing potential harm. In conclusion, the combination of protective coatings, coil coating processes, proper handling, and storage practices ensures that aluminum coils remain well-protected from scratches and damage, thus maintaining their quality and appearance.

- Q: Can aluminum coils be used in the production of aircraft fuel tanks?

- Yes, aluminum coils can be used in the production of aircraft fuel tanks. Aluminum is a commonly used material in the aerospace industry due to its lightweight, strong, and corrosion-resistant properties. It is an ideal choice for fuel tanks as it can effectively withstand the harsh conditions and requirements of aircraft operations.

- Q: A certain ionic compound is made entirely of aluminum and oxygenWhat is the formula for this compound?

- Aluminum Oxide Al2O3

Send your message to us

Chocolate Brown Aluminum Coil - Aluminium Prepainted PVDF with 10μ 1100 H18

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords