Chinese Better Pre-Painted Galvanized/Aluzinc Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

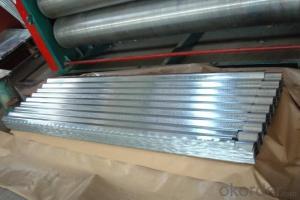

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the different types of steel coil packaging materials used during processing?

- Some of the different types of steel coil packaging materials used during processing include steel strapping, plastic strapping, stretch film, shrink wrap, and coil covers.

- Q: I am looking to weld some stainless steel using stainless electrodes. I was told that the arc welder needs to be able to run in DC in order to be able to weld stainless steel. Is this true? Or can you weld stainless steel with stainless electrodes with AC also?

- there are tradeoffs to the various methods you can use. Check out this link for the scoop on what they are and what the settings should be given the material you are using and the type of welder you decide to use.

- Q: How are steel coils processed at the steel service centers?

- Steel service centers process steel coils through a series of steps to transform them into finished products that meet the specific requirements of customers. The process typically begins when the steel coils arrive at the service center. These coils are usually large and heavy, and they may have been produced by a steel mill or imported from overseas. Upon arrival, the steel coils undergo a quality inspection to identify any defects and ensure that only high-quality coils are used in the production process. After inspection, the coils are stored in a warehouse until they are ready for processing. Next, the steel coils are uncoiled to create flat sheets of steel. This can be done manually or using automated machines, depending on the size and thickness of the coils. The uncoiled steel is then leveled to remove any residual stress and ensure a flat and consistent surface. Once leveled, the steel sheets go through various processes based on the desired end product. These processes may include cutting, shearing, slitting, and forming. Cutting and shearing involve shaping the steel sheets into specific sizes or shapes. Slitting involves cutting the steel into narrow strips, while forming involves bending or shaping the steel. After the desired processing operations are completed, the steel sheets are often treated with surface finishes to enhance their appearance or protect them from corrosion. These finishes may include painting, coating, or galvanizing. Finally, the processed steel sheets undergo another quality inspection to ensure they meet the required specifications. They are then packaged and prepared for shipment to customers in industries such as construction, automotive, or manufacturing. Overall, the processing of steel coils at steel service centers involves a combination of inspection, uncoiling, leveling, cutting/shearing/slitting/forming, surface finishing, quality control, and packaging. This process allows for the transformation of steel coils into finished products that are customized to meet the specific needs and requirements of customers.

- Q: I have a carbon steel file that I want to bend in a letter C shape. So, what is the malliable temperature? If it's low, could it be done in a camp fire?

- It needs to be RED hot, the hotter the better. Yes you can use a camp fire if you put the file directly in the hottest part of the coals, but it'll take about 5-10 minutes to heat. Charcoal briquettes would probably work better as a heat source. You can use something like a blow dryer to intensify the coals, that might help. You'll also need a bench vice, and the biggest pair of pliers you can find, for leverage. Bending steel's not easy even when it's hot. You could also use a bit of steel pipe that'll fit over the end of the file. Stick the file in the vise when red-hot, slip the pipe over the free end, and use the pipe to bend it. OR, you could use the old-fashioned method of just holding it with pliers in one hand, and hitting it with a 5lb sledge hammer with the other. use something solid as an anvil, like a large steel pipe. you mighe be able to get away with using a small log, but you'll have to work twice as hard. Safety glasses are MANDITORY for this type of thing. Do not attempt without eye protection at all times. Ear plugs are also a very good idea.

- Q: i need working shoes for women that have steel toe shoes? What store do they sell them in . i live in c.a.

- Walmart Steel Toe Shoes

- Q: What are the common surface defects in steel coils?

- Common surface defects in steel coils include scratches, rust, scale, pits, and stains.

- Q: Can steel and/or stainless steel turn rusty ?

- Steel will rust. Stainless Steel does not rust.

- Q: Can steel coils be coated with ceramic?

- Yes, steel coils can be coated with ceramic. Ceramic coatings provide a protective layer that enhances the corrosion resistance, heat resistance, and durability of the steel coils. Additionally, ceramic coatings can also offer improved electrical insulation and thermal barrier properties.

- Q: Is there alloys in low carbon steel or non

- Steel is an alloy. An alloy is a mixture of metals melted together, a solid solution. There are many recipes for steel depending on what the use is. Steel is an alloy of iron and another metal .Low carbon steel has less than 0.3% carbon, carbon steel is 0.3 to 0.6% carbon Low carbon steels generally contain less than 0.25% carbon and cannot be strengthened by heat-treating (strengthening can only be accomplished through cold working). The low carbon material is relatively soft and weak, but has outstanding ductility and toughness. In addition, it is machineable, weld-able, and is relatively inexpensive to produce. Carbon steel, also called plain carbon steel, is steel where the main alloying constituent is carbon. The American Iron and Steel Institute (AISI) defines carbon steel as: Steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 0.40 percent; or when the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65, silicon 0.60, copper 0.60.

- Q: How are steel coils used in the manufacturing of industrial pumps?

- Steel coils are used in the manufacturing of industrial pumps as they provide a strong and durable material for constructing pump components such as casings, impellers, and shafts. The coils are typically cut, shaped, and welded to create the necessary parts, ensuring the pumps can handle high pressures and harsh operating conditions in various industries.

Send your message to us

Chinese Better Pre-Painted Galvanized/Aluzinc Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords