China Lime Silica Aluminum Silica Refractory Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for China Aluminum Silica Refractory Brick

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Mullite |

| SiO2 Content (%): | 0 | Al2O3 Content (%): | >48 | MgO Content (%): | 0 |

| CaO Content (%): | 0 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0 |

| SiC Content (%): | 0 | Model Number: | follow as customer's requirement | Brand Name: | |

| Size(mm): | 230x114x65/75 | Refractoriness(°C): | ≥1750-1790 | Bulk Density (g/cm3): | 2.2-2.3 |

| Apparent porosity(%): | ≤22-23 | Cold crushing strength (Mpa): | ≥39-54 | Refractoriness under load(0.2MPa) (°C): | ≥1420-1520 |

| Reheating Linear Change: | +0.1~ -0.4 |

Packaging & Delivery

| Packaging Details: | on wooden pullet covering by PE membrane or by customer's requirment |

| Delivery Detail: | within 30days after deposit |

Product Description

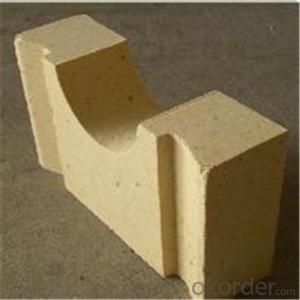

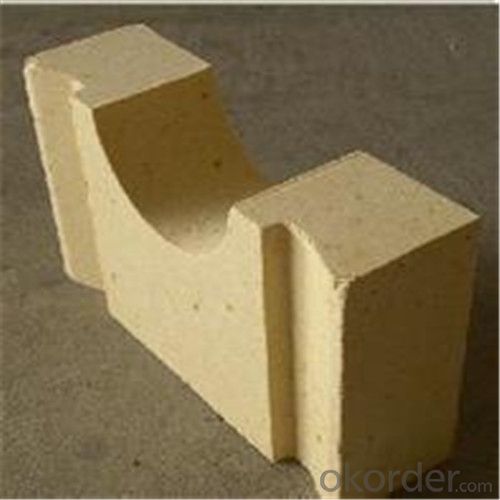

High Alumina Brick/Rrefractory Brick/Fire Brick

High alumina brick refers to fire brick containing Al2O3 more than 48%, which is made of high grade bauxite through high temperature calcinations. High alumina brick is a kind of neutral refractory material so that it enjoys excellent resistance to acid and alkali corrosion. It has characteristic of high refractoriness under load, which decide high alumina brick is a n ideal material for various kinds of industrial furnace. It is widely used in building lining of hot-blast stove, blast furnace, coke oven, rotary kilns of cement and so on. | |

Product name | China aluminum silica refractory brick |

Size and Specifications | 230x114x65mm 230x114x75mm

Special size brick is also available according to your drawings. |

Type | High Alumina Brick

|

Characteristics | 1 Excellent thermal stability 2 High refractoriness under load 3 Chemical stability and anti-corrision 4 Small high temperature creep rate 5 Excellent thermal shock resistance |

| Typical Use | 1 Building materials for blast furnace 2 Building materials for hot-blast stove 3 Building materials for coke oven 4 Building materials for steel making furnace 5 For ladle 6 For construction material in steel industry |

Operating Temperature | 1770°C |

Service | The size, density, chemical composition can be customized. |

Port | Qingdao Port |

Payment terms | L/C, T/T, D/A, D/P, Western Union, MoneyGram, Cash |

Delivery | Within 30 days after receiving deposit |

Packing | wooden pallet with shrinkage film, paper protect angle. |

Certificate | ISO 9001 |

Physial properties and chemiacal composition

Item | SK38 | SK37 | SK36 | SK35 |

Al2O3 % | ≥75 | ≥65 | ≥55 | ≥48 |

Fe2O3 % | ≤2 | ≤2 | ≤2 | ≤2 |

Refractoriness °C | ≥1790 | ≥1770 | ≥1750 | ≥1420 |

Apparent porosity % | ≤23 | ≤23 | ≤22 | ≤22 |

Cold crushing strength Mpa | ≥53.9 | ≥49.0 | ≥44.1 | ≥39.2 |

Refractoriness under load(0.2MPa) °C | ≥1520 | ≥1500 | ≥1470 | ≥1420 |

Reheating Linear Change % | +0.1(1500°C, 2h) | -- | ||

-0.4(1400°C, 2h) | -- | |||

Our competitive Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Lower ferric Oxide,porosity,higher refractoriness,density,higher CCS and exact tolerance.

5.Strict Quality Control. Meet clients’ quality requirement.

6.Safty packing,prompt delivery time,and excellent after-sales services.

7.Large stocks. Guarantee prompt delivery.

8.Professional Packing. Avoid damage and secure the goods in transportation

Warmly welcome friends and customers all over the world to pay a visit to factory!Hopefully both of us can establish a long-term cooperation!

Packaging & Shipping

1.Packing by Plastic film and pallets or wooden box and others as requested.

2.Shipping by 20Ft container.

3.For more details of our products and others.Please kindly contact us.

FAQ

3.Common question:

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

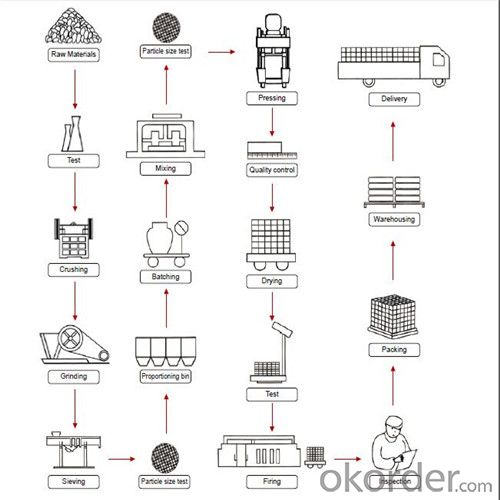

- Q: Why will expand when heated brick

- Because the production of raw materials are silica brick, brick with SiO2 content of not less than 95% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- The main damage of silicon carbide side wall brick is stress damage, not chemical erosion. Chemical damage is formed prior to the formation of the groove, and the damage to the chemical erosion is little after the formation of the groove.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Brick bearing soft temperature and close to the melting point, high temperature strength, can be in high temperature (above 1400 degrees) under the condition of long-term use,

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into phosphorus and quartz. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- The share of A12O3 and SiO2 is different

- Q: The brick is mainly used in the place?

- Partitions used in coking and combustion chambers for coke ovens

- Q: What are the main constituents of refractory bricks?

- (a) containing refractory brick brick, refers to more than SiO293%, is the main varieties of acid resistant brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

- Q: High temperature refractory material?

- Special materials often use AZS brick (i.e. corundum brick), corundum brick, magnesia chrome bricks, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Insulation refractories are often used diatomite products, asbestos products, insulation board. Unshaped refractories are often used refractory castable, refractory clay, refractory ramming material, refractory plastic and fettling material, fire resistance, gunning, refractory cast material, fireproof coating, lightweight refractory castable, gun mud.

Send your message to us

China Lime Silica Aluminum Silica Refractory Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords