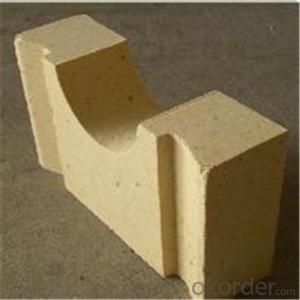

Silicon Carbide Silica Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

SI3N4 SICStable chemical performance

High cold crushing strength

Good thermal shock stability

Good anti corrosion ability

SI3N4 bonded SIC brick.

Stable chemical performance

High cold crushing strength

Good thermal shock stability

Good anti corrosion ability

It is mainly used in the production of aluminum,copper, zinc.

It is used as the liner of molten bath or electrobath.

SI3N4 SIC brick has no corrosion with metal aluminum, and has no chemical reaction with cryolite. It is the ideal material for electrobath lining brick.

Item Brand Index | For General Purpose | Light weight silica brick | ||

GZ-95 | GZ-94 | GZ-93 | QG-1.2 | |

SiO2≥ | 95 | 94 | 93 | 91 |

Refractoriness | 1710 | 1710 | 1690 | 1670 |

RUL(0.2 MPa)T1, °C | 1650 | 1640 | 1620 | 1560 |

Apparent Porosity% | ≤22 | ≤23 | ≤25 | ≥45 |

Cold Crushing Strength Mpa | ≥29.4 | ≥24.5 | ≥19.6 | ≥3.5 |

True Density g/cm3 | ≤2.37 | ≤2.38 | ≤2.39 | ≤2.39 |

Bulk Density g/cm3 | ≤1.20 | ≤1.20 | ≤1.20 | ≤1.20 |

Item | Data |

Apparent porosity,% | ≤17 |

Bulk density,g/cm3 | ≥2.6 |

Cold crushing strength,Mpa | ≥150 |

Crushing strength at 1400°c,Mpa | ≥43 |

SiC, % | ≥72 |

Si3N4, % | ≥21 |

Fe2O3, % | ≤1.5 |

Anti-alkaline | Good |

- Q: Physical solid waste disposal

- The production of silicon material is added to the cause of waste brick:Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products during firing

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- How to keep the brick masonry temperature not lower than 600 DEG C, while the exhaust temperature is not higher than 400 DEG C.

- Q: Common bond brick?

- Lime should contain a lot of active CaO, I decompose CaCO3 and MgCO3 not more than 5%, Al2O3+Fe2O3+SiO2 no more than 5%. When the content of large particles, burned Ca-CO3 and over burned lime, the product produced caves, affecting the quality of products.

- Q: Why will expand when heated brick

- After high temperature after the formation of tridymite and cristobalite and quartz and a small amount of residual glass phase, quartz heating to 220-240 DEG C, in a certain degree of thermal expansion, brick maximum expansion occurs in 100~300 DEG C, 300 expansion before the total amount of expansion is about 70%~75%.

- Q: Semisilica brick interpretation

- Good thermal shock resistance. In use, more high viscosity glass phase can be formed, and the masonry brick joint and the working surface are dense and the masonry is complete, which is beneficial to improve the impermeability of the masonry and reduce the erosion effect of the slag on the masonry.

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Mainly used for coke oven carbonization chamber and the combustion chamber wall, open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace, refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance.

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick with silicon oxide content, low melt index, mainly used for glass kiln crown, parapet, wall hanging, small furnace arch superstructure and regenerator.

- Q: Which material is good for furnace refractory?

- Basic refractories in Magnesium Oxide and calcium oxide as the main ingredient, commonly used is brick. Magnesium Oxide 80% to more than 85% containing magnesia brick, has good resistance to alkaline slag and slag, refractory clay brick and brick high ratio. Mainly used in open hearth furnace, oxygen converter, electric furnace, non-ferrous metal smelting equipment and high temperature equipment.

- Q: The brick is mainly used in the place?

- Partitions used in coking and combustion chambers for coke ovens

Send your message to us

Silicon Carbide Silica Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords