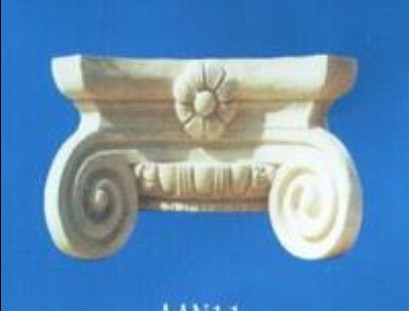

China Column Head Mould-4

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 50000000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of China Column Head Mould:

It is made by the special GRG high-strength powder mixing with the high-strength alkali-free fiberglass and reinforcer. To increase the strength of the structures, we will embed wooden timbering, galvanized keel, fiberglass rob, fiberglass mesh cloth. The products are featured by high strength, good flexibility and good resistance to impact. So it is widely used in senior clubs, five-star hotels, luxury villas, modernization office building.

Applications of China Column Head Mould:

Our main products are gypsum one-piece art ceiling , gypsum cornice, gypsum ceiling corner, decorative sideline, chair rail, decorative beading, relief, Roman Pillar, gypsum corbel, centre medallion, niches, fireplace etc.

- Q: Can a grenade blow through brick/cement wall?

- Why are you planning to hide behind a brick/cement wall? LOL!! Yes depending on what type of grenade is deployed a brick or cement wall is nothing to blow through. You would be surprised at what a concussion grenade will do to a wall.

- Q: I'm doing a small outdoor project and I need to stick some construction paper on to painted aluminum. I have some rubber cement from a craft store. Will this adhere to the metal and survive outdoor conditions of snow, wind, rain etc?

- Nope. Contact cement would be better. But I don't think anything will last long out of doors. Even the paper will start to fall apart after the first rain or heavy dew. And the sun will also cause it to decompose. Paper does not do well outside. You may have to rethink your project.

- Q: Ferro-cement was the quot;inquot; material to make a boat hull from, and my father was quite taken with the idea behind it. Time and my father have passed, and I am wondering if it is still a viable building material. thank you for your responses.

- If made by a professional, the concrete hull has lots of advantages over its FRP cousin. The concrete gets harder as time goes on. The first one made in the 1860's is still afloat. Cement does not blister or delaminate. The weight can be a read advantage when sailing in choppy seas as it will plow through waves that will stop a lighter vessel. If one should encounter a situation that would hole a FRP vessel, the ferro will cave in like an eggshell. Kick it back in shape, slap some fresh cement on it and off you go. Down side is dealing with marinas. They think that you will come flying into your slip and destroy the dock. As long as you are aware of your extra weight and adjust your maneuvers there should be no problems.

- Q: How many bags of cement do you have in 1 cubic meter of concrete mixed in the ratio 1:4:8?

- 3 x25kg bags of cement for 1 kub concrete.......what a joke !!!!! There is 16 wheel barrows in a kub of sand + stone mix (normally 50-50 sand to stone ) For every 4 wheel barrows you use 1 bag of 50kg of 32.5 cement So.....it gives you 4x50kg cement to mix 1 kub of concrete. The slump depends on what you wanna use the concrete for........it means if you need concrete for floor screeting you are going to use less water( it will be a more stiff mix ) More water added for foundations and big floor areas where you will use rolers to flatten out and after drying for about 6 hours you apply the mechanical machines for screeting. Make sure you screet through the slurry.(polish the floor and not the screet). Its better to make use of ready mix with a % fibre in the mix for big area flooring and try to work in the shade.....ok?....Happy hunting..

- Q: I remember our new middle school (back when I was in middle school) was brand new. And most kids have a (non-serious) fantasy about their school burning down, but it almost entirely made of painted cement blocks.Cement, I think can be burned/charred if say you hold a blowtorch/flamethrower to it, or douse it with gasoline and ignite it, but I don't think it can catch fire and have it spread like wood can. I know the twin towers collapsed but that was because an plane flew into them. It was the engine fuel that burned it. For a fire to catch and spread and become really strong, it needs some decent food/combustible fuel like wood to get a strong fire going.

- no, but the things inside the building will burn up. concrete doesn't burn, but intense heat can make the mortar crumble.

- Q: I would like to build a wall and I understand that just fine however the floor is cement so I obviousy can't just throw some nailes into it. Any tips would be appreciated it will be in my basement

- all you need is to go to Lowe's or a 84 lumber and get concrete screws Simpson Strong Tie screws for concrete they come with a bit to predrill the holes these are better then using concrete nails cuz they cant grab the floor good enough

- Q: I have got some chemistry prep and one of the question are ' How do u make cement ? ' Please could you help ! thanks :)

- Try okorder ur answer is there

- Q: I tried to set anchor but its to sandy and i drove it straight through. I'm assuming I need to replace? Is there anything else I can do to cure the concrete to make it hard?

- I mix my cement rich 1 cement to 2 1/2 sand and 1 pea gravel. The cement bags recommend 1 cement to 3 sand and 2 gravel. But under developed countries use 1 cement to 6 sand and 2 gravel. -- it is weaker but it cures hard in about 3 or 6 weeks depending on the humidity in the area and how thick the cement was poured.. So don't do anything drastic until you give your concrete porch more time to cure and get harder.

- Q: What kind of drill do I need to easily drill holes into the cement sub-floor of my house (for a flooring project)? I've already tried two different types of masonry bits with my cordless, 18 volt Bosch (model 3850). I'm thinking that the bit isn't the problem, it's the drill. It takes about 10 minutes and a way too much effort just to drill one hole. Any suggestions?

- The previous answers are correct. Rent a good SDS bit hammer drill and it will drill your concrete as easy as sticking your finger in butter. You'll drill all those holes so fast you won't believe it. Those masonry bits used with a regular rotary drill are only good for drilling mortar joints or soft brick. As you already discovered, they are just not adequate for concrete. Actually, if you do a lot of your own work, a residential grade 120 volt DeWalt hammer drill is not that expensive and a handy thing to own. I have one myself -- it can be used on rotary or hammer settings.

- Q: looking for way to inlay small stones or pea gravel into new cement walk way?

- its also a plus if you dont have bad snowy winters. this finish is not really for harsh climates. i wouldnt do it where i live and im a finisher...

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2000 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Lianyungang PORT |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

China Column Head Mould-4

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 50000000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords