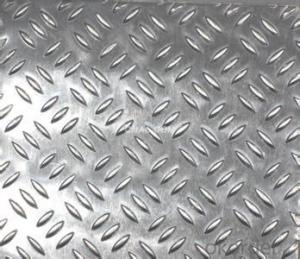

China Aluminum Coil Price AA 3003 Stucco Embossed Aluminium Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

supply Mill-finished / coated aluminum sheet/ coil:

Alloy: AA1050,1060,1100,1200,2024,3003,3304,3005,3015,5052,5086,5754,5083,6061,7050,7475,8011, etc

Temper: O, H14/16/18/22/24/32/ H112/H321/T6,T851,T7451,T7351, etc

Thickness: 0.02mm—20mm

Width: 100mm—2000mm (Can be slitted)

Notice: PE coating / PVDF coating / Embossment can be done if required.

- Q: Is aluminum veneer the same as color coated aluminum coil?

- Not necessarily, but you may call it like this. Aluminum veneer is the panel processed by aluminum plant. It has different size and thickness according to customer’s requirements. Color coated aluminum coil has been coated through two processes of bake and roast, for example, the coil or sheet formed of the coating of cars.

- Q: Can aluminum material be utilized as a baking surface for bread?

- <p>Aluminum coils are not typically used for baking bread. While aluminum is a good conductor of heat and is used in baking sheets and muffin tins, it's usually in a flat, solid form. Aluminum coils, often used for industrial purposes like heat exchangers, are not designed for direct food contact. For baking bread, it's best to use materials specifically designed for baking, such as silicone mats, parchment paper, or non-stick baking sheets. These materials are safe for food contact and can withstand the high temperatures required for baking bread.</p>

- Q: What will be the pros and cons of using each of these materials?One thing to keep in mind is that aluminum alloys are good conductors of electricity.

- Alloy Ladders

- Q: Can aluminum coils be used for HVAC systems?

- Yes, aluminum coils can be used for HVAC systems. Aluminum coils are commonly used in HVAC systems as they offer several advantages over other coil materials. Firstly, aluminum is a lightweight material, which makes it easier to handle and install. This can result in lower installation costs and reduced strain on the structure of the HVAC system. Secondly, aluminum coils have excellent heat transfer properties. They efficiently transfer heat from the refrigerant to the surrounding air, which is crucial for the effective functioning of the HVAC system. Aluminum coils also have a high resistance to corrosion, which is particularly important in humid environments or areas with high levels of pollutants. Additionally, aluminum is a highly recyclable material, making it an environmentally friendly choice for HVAC systems. It can be easily recycled and reused, reducing the need for new material extraction and minimizing waste. Overall, aluminum coils are a reliable and efficient choice for HVAC systems, providing excellent heat transfer, durability, and environmental sustainability.

- Q: What are the environmental regulations concerning the use of aluminum coils?

- <p>Yes, there are environmental regulations that govern the use of aluminum coils. These regulations vary by country and region but often include restrictions on emissions, waste disposal, and recycling requirements. For instance, in the United States, the Environmental Protection Agency (EPA) enforces rules that control the release of pollutants from aluminum production facilities. Additionally, there are guidelines for the proper disposal of aluminum waste to prevent environmental contamination. Recycling regulations also encourage the reuse of aluminum coils to reduce the environmental impact of mining and production. Compliance with these regulations is crucial for businesses that manufacture or use aluminum coils to avoid penalties and ensure sustainable practices.</p>

- Q: This question asks about the maintenance difficulty of aluminum coils.

- <p>Aluminum coils are relatively easy to maintain. They are resistant to corrosion and do not require frequent cleaning or special treatments. Regular inspection for any physical damage or signs of wear is sufficient. However, it's important to keep them dry and clean to prevent any potential issues. For specific applications, such as in HVAC systems, regular cleaning may be necessary to ensure optimal performance. Overall, maintenance is minimal compared to other materials.</p>

- Q: Can aluminum coils be bent or shaped?

- Yes, aluminum coils can be bent or shaped. Aluminum is a highly malleable and ductile metal, meaning it can be easily manipulated and formed into various shapes without breaking or cracking. The flexibility of aluminum allows it to be bent, rolled, or shaped into coils, making it a popular choice for various applications such as in the manufacturing of air conditioning systems, automotive parts, and packaging materials. The ability to bend and shape aluminum coils makes them versatile and adaptable to specific design requirements, allowing for efficient and precise customization in various industries.

- Q: What is the reflectivity of aluminum coils?

- The reflectivity of aluminum coils is typically high, as aluminum is known for its excellent reflective properties.

- Q: What are the different protective film options for aluminum coils?

- There are several protective film options available for aluminum coils, each offering specific benefits and suitability for different applications. Some common options include: 1. PVC (Polyvinyl Chloride) Film: PVC films are widely used for protecting aluminum coils due to their excellent resistance to moisture, chemicals, and abrasion. They provide a high level of surface protection and are available in various thicknesses and adhesive strengths. 2. PE (Polyethylene) Film: PE films are another popular choice for protecting aluminum coils. They offer good resistance to moisture and UV radiation and are generally more cost-effective than PVC films. PE films are available in different grades, including low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE). 3. PP (Polypropylene) Film: PP films are known for their excellent tear resistance and high tensile strength. They provide good protection against mechanical damage and are suitable for applications where coils may undergo rough handling or transportation. 4. PET (Polyethylene Terephthalate) Film: PET films offer outstanding clarity and transparency, making them ideal for applications where visual inspection of the coils is required. They also provide good resistance to heat, chemicals, and abrasion. 5. Adhesive Coatings: In addition to films, adhesive coatings are sometimes used to protect aluminum coils. These coatings are typically applied directly to the surface of the coil and form a protective layer against moisture, corrosion, and scratching. When selecting a protective film for aluminum coils, it is essential to consider factors such as the intended application, environmental conditions, handling processes, and desired level of protection. Consulting with a supplier or manufacturer can help determine the most suitable option for specific requirements.

- Q: Is it appropriate to use a hammer to open or unroll an aluminum coil?

- <p>Using a hammer to open an aluminum coil is not recommended. Hammers are designed for striking and can easily damage the aluminum, causing dents or deformation. Instead, use a pry bar or a similar tool to gently unroll the coil without applying excessive force. This will help prevent damage to the aluminum and ensure it remains in good condition for further use.</p>

Send your message to us

China Aluminum Coil Price AA 3003 Stucco Embossed Aluminium Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords