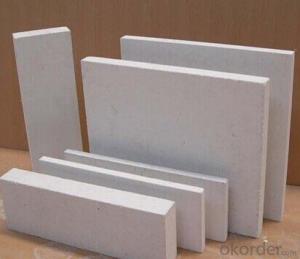

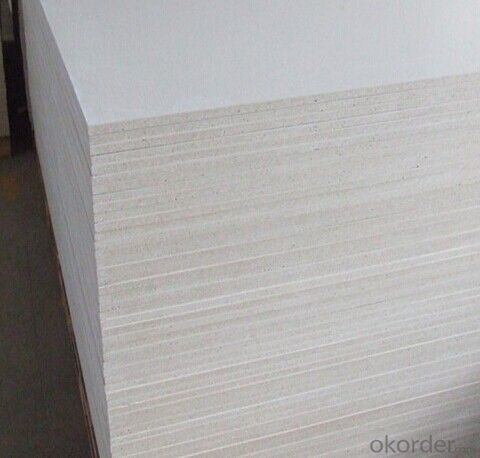

Magnesium Oxide Fireproof Board (mgo board) Europe Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

2) Swelling rate: 0.34%

3) Heating contraction: 1.2%

4) Density: 0.95-1.1g/cm3

5) Dry bending resistance: 16Mpa

6) Sound insulation: 44 dB

7) Heat-transfer coefficient: 0.14w/mk

8) Environmental friendly: Free of asbestos, formaldehyde and ammoni

Using places:

DESCRIPTION

Magnesium oxide board is made from Magnesium Oxide(MgO), Magnesium Chloride(Mgcl2), fiberglass mesh, sawdust, perlite etc.,using highly purified active MgO as the main fireproof material of board, high-quality MgCl2 as the main cementing material to solidify other materials, alkali-resistance fiberglass mesh to ensure the high strength of board, soft sawdust and light non-combustible perlite as filling materials. It is a kind of Eco-friendly fireproof board widely used in construction and decoration.

(Pave slurry on the surface of MGO board to reduce the holes, make the surface more smoothness and less holes. Slurry paved board is a kind building material to further process.Suit to stick thin decorative material or paint on the board.)

- Q: Aluminum sheet tensile test, the sample direction is horizontal or vertical sampling? What is the relationship between the longitudinal specimen, the transverse specimen and the rolling direction of the sheet?

- In general, we do the tensile test are selected longitudinal, we usually refer to the longitudinal direction of the plate rolling (commonly known as the X-axis direction), because of its rolling in general tensile strength than the lateral High, horizontal is generally perpendicular to the rolling direction, of course, some of the material is longitudinal rolling, horizontal stretch, such as some thin film materials, usually through the stretch of the lateral stretch than did not have to stretch the big. ?? Another tensile test depends on your main focus on the performance, different performance depends on the different indicators of data.

- Q: Guodong E1 grade 180 plate how to identify

- Guodong is actually only a very popular in the southwest region of the logo, only a logo only, no one can identify whether it is authentic, do not mind too. Any special emphasis on your own use of the country ah LSH Ye like the plate, you should be careful. Our industry, as long as it is out from the manufacturers, are clear Guodong is not any security LOGO (and can not be tested to prove that Guodong produced), and the Guodong like the plate manufacturers are not directly The use of furniture, must be treated through the finishes will enter the furniture factory, and this finishes the process, the importance of the original sheet than ever. Or the words: the economic market, is always a penny of goods (aside from those who do not speak integrity of the business, because their behavior can not be used to measure the normal business theory) Guodong is actually only a very popular in the southwest region of the logo, only a logo only, no one can identify whether it is authentic, do not mind too. Any special emphasis on your own use of the country ah LSH Ye like the plate, you should be careful. Our industry, as long as it is out from the manufacturers, are clear Guodong is not any security LOGO (and can not be tested to prove that Guodong produced), and the Guodong like the plate manufacturers are not directly The use of furniture, must be treated through the finishes will enter the furniture factory, and this finishes the process, the importance of the original sheet than ever. Or the words: the economic market, is always a penny of goods (aside from those who do not speak integrity of the business, because their behavior can not be used to measure the normal business theory)

- Q: Bunny plate prices and Moganshan plate which is of good quality, expensive?

- Moganshan quality is better. Bunny this brand is good, but we are very difficult to buy real goods here The Or that I see is the real thing, then I can only say, pit father ah

- Q: Teach you how to distinguish between the quality of integrated ceiling plate?

- Integrated ceiling plate classification Rolling board: resistant to decay, resistant to powder, corrosion resistance; Nano-board: resistant to decay, more self-cleaning, anti-fumes; Covered board: anti-fumes, wear-resistant, moisture-proof, feel good, color and more; Drawing board: high-quality substrate, imported diamond cloth wheel surface pull pattern, a variety of chemical treatment, sound insulation, corrosion, board shape effect is good, bright color; Anodized plate: temperature, the surface does not fall off, 20 years do not fade, scratch, wear, easy to scratch, anti-static, anti-interference, anti-electromagnetic radiation, anti-ultraviolet, no dust, The

- Q: I only know plywood.MDF is a kind of plywood? Is MDF different from another board of plywood or just a piece of wood?

- 1, MDF is a medium density fiberboard (English name: Medium Density Fiberboard, abbreviated as MDF, referred to as MDF). 2, medium density fiberboard is a wood fiber or other plant fiber as raw material, broken, fiber separation, drying urea urea resin or other suitable adhesive, and then made by hot pressing a man-made sheet. Its density is generally in the range of 500-880 kg / cubic meter, the thickness is generally 5-30 mm. 3, medium density fiberboard is the mid-sixties developed products, in recent years the rapid development of production. Because it has excellent physical and mechanical properties, decorative properties and processing performance.

- Q: See a lot of people with black frame, comfortable?

- The board is light and the texture is wearing a very comfortable type!

- Q: Jumping rabbit plate quality is good

- Jumping rabbit plate good, blockboard in the industry or famous.

- Q: South Asia, Health benefits, Teng Hui FR4, which is relatively expensive?

- Health benefits of expensive, generally large PCB factory are selected benefits of the plate. South Asia is better ink, Tenghui metal substrate plate can also be

- Q: How to distinguish between true and false Qingdao wood of the big core board

- 1, look at the manufacturer's trademark, production address, security signs and so on. Now fake big brand "near the brand" products too much. Of course, now some of the counterfeit products really super difficult to distinguish between true and false, it can only once again carefully read. 2. Look at the appearance of big core board. See whether the surface of the big core board, with or without warping, deformation, with or without blistering, depression. If the bonding strength is not good, weigh its corner will be "creak" open plastic sound. And then with the mouth of the device to knock the surface of the plate, listen to the sound is very different, if the sound has changed, indicating the existence of hollow inside the plate. And see whether there is no glue around, putty, generally putty are to cover up. 3. See if there is a smell. If the big core plate distributed fragrance of wood smell, indicating less formaldehyde release; if the smell pungent, indicating more formaldehyde release, do not buy. Tell the truth now on the market to the people to decorate the majority of E2 board, E1 rarely find, E0 less, a lot even if the paste E1 or E0, in fact, not necessarily true compliance, as long as the above 3:00 no problem Basically nothing, and more to take a few look like a good decoration is the most important ventilation is more than a month or more to distribute formaldehyde.

- Q: Recently visit the building materials market to buy furniture, see a lot of style almost furniture, the price is a lot of difference, ask the sales staff is what the reasons, sales staff said that this is because the furniture used by the plate is not the same, the production of furniture made of plate than the domestic plate production Furniture, some of my puzzled, is the quality of imports of sheet metal production is really better than the quality of domestic furniture produced by the plate ok ...

- Imported sheet metal produced by the following differences: 1, the import of the plate, if the election is white, the import of white than the domestic more pure; 2, the density of imported plate plate heart is higher; 3, the taste of imported plates will be smaller; 4, there is an intuitive approach, due to the high density of imported plates, so the same size of the plate than the domestic weight.

Send your message to us

Magnesium Oxide Fireproof Board (mgo board) Europe Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords