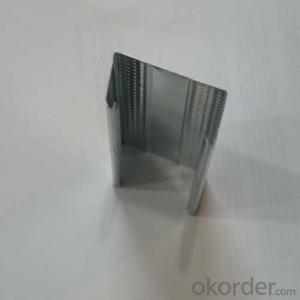

Channel Steel Galvanized Hat Furring for House, Wall, Ceiling,Purlin

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Channel Steel Galvanized Hat Furring for House, Wall, Ceiling,Purlin at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Channel Steel Galvanized Hat Furring for House, Wall, Ceiling,Purlin are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Channel Steel Galvanized Hat Furring for House, Wall, Ceiling,Purlin are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

a. Usage: Building framework, car manufacturing and other industrial structures

b. Packing: Export seaworthy package, or according to the customers’ need.

c. Weight tolarance: -4% TO -10%

d. Inspection: accept third party inspection

GB STANDARD HOT ROLLED CHANNEL STEEL | |

SIZE (MM) | THEORETICAL WEIGHT (KG/M) |

50*37*4.5 | 5.44 |

63*40*4.8 | 6.635 |

80*43*5 | 8.045 |

100*48*5.3 | 10.007 |

120*53.5.5 | 12.06 |

140*58*6 | 14.53 |

140*60*8 | 16.73 |

160*63*6.5 | 17.23 |

160*65*8.5 | 19.755 |

180*68*7 | 20.17 |

180*70*9 | 23 |

200*73*7 | 22.637 |

200*75*9 | 25.777 |

220*77*7 | 24.999 |

220*79*9 | 28.453 |

240*78*7 | 26.86 |

240*80*9 | 30.628 |

250*78*7 | 27.41 |

250*80*9 | 31.335 |

280*82*7.5 | 31.427 |

300*85*7.5 | 34.463 |

320*88*8 | 38.083 |

360*96*9 | 47.814 |

JIS STANDARD HOT ROLLED CHANNEL STEEL | |

SIZE | THEORETICAL WEIGHT |

50*25*3.00~5.00*6 | 2.37~3.46 |

75*40*5*7 | 6.92 |

100*50*3.8*6 | 7.3 |

100*50*4.2*6 | 8.03 |

100*50*4.5*7.5 | 8.97 |

100*50*5*7.5 | 9.36 |

125*65*5.2*6.8 | 11.66 |

125*65*5.3*6.8 | 12.17 |

125*65*5.5*8 | 12.91 |

125*65*6*8 | 13.4 |

150*75*5.5*7.3 | 14.66 |

150*75*5.7*10 | 16.71 |

150*75*6*10 | 17.9 |

150*75*6.5*10 | 18.6 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Steel Channel is a groove-shaped cross-section of the steel strip. Channel mainly used for building structure, curtain wall engineering, machinery manufacturing and other equipment and vehicles. In use required to have good welding, riveting performance and mechanical properties.

Steel Channel refers to a channel hot-rolled, hot-rolled steel sheet production process and, as the ingots are heated to a certain temperature, the basic steel into the thermoplastic state, then formed by rolling mill. Cold-rolled and cold-formed channel steel production process is basically the same, refers to the steel at room temperature through external action, will be made of steel rolled or curved shape needed. Due to the large difference between the two production processes, therefore, the two are very different performance, hot-rolled steel sheet or hot-rolled steel cold-rolled low intensity ratio, but the plastic deformation ability.

The specifications to waist high (h) * leg width (b) * waist thick (d) the number of millimeters expressed as 120 * 53 * 5, showing the high waist of 120 mm, leg width of 53 mm channel, thick waist 5 mm channel, or 12 # channel. Waist high the same channel, if several different legs wide and thick waist also need to model the right plus a b c be distinguished, such as 25a # 25b # 25c # and so on. Under normal circumstances, the same model (the same value) channel, b-type legs wide and thick waist is greater than a number, so the value per unit length of the same channel type, b-type than a heavy type.

- Q: What are the common fire protection measures for steel channels?

- Some common fire protection measures for steel channels include applying fire-resistant coatings or intumescent paint, wrapping them with fire-resistant insulation materials, installing fire-resistant barriers or enclosures around them, and ensuring proper spacing and ventilation to prevent heat buildup. Additionally, fire detection and suppression systems such as smoke detectors, sprinklers, or fire extinguishers can be installed to quickly respond to any fire incidents.

- Q: How do steel channels contribute to the overall sustainability of a structure?

- There are several ways in which steel channels contribute to the overall sustainability of a structure. Firstly, steel is an incredibly durable and long-lasting material. It has resistance to corrosion, weathering, and degradation, meaning that structures built with steel channels have a longer lifespan compared to those made with other materials. This durability reduces the need for frequent repairs or replacements, ultimately decreasing the environmental impact associated with construction and demolition waste. Moreover, steel channels are both lightweight and strong, allowing for the efficient use of materials. This means that less steel is needed to achieve the same structural strength, resulting in reduced resource consumption and energy usage during the manufacturing process. Additionally, steel is a recyclable material, meaning that steel channels can be easily repurposed or recycled at the end of their life cycle. By recycling steel, the demand for new raw materials is reduced, and the energy required in the production of new steel is saved. Furthermore, steel channels offer great design flexibility and versatility, enabling architects and engineers to create innovative and sustainable structures. They can be easily shaped, welded, and assembled, making the construction process easier and allowing for a wide range of architectural designs. This flexibility also allows for future modifications or expansions without the need for extensive demolition or reconstruction. Lastly, steel channels possess excellent fire resistance properties. Steel is non-combustible and does not contribute to the spread or intensity of fires, enhancing the safety of the structure and reducing the risk to occupants and neighboring buildings. In conclusion, steel channels contribute to the overall sustainability of a structure through their durability, efficient use of materials, recyclability, design flexibility, and fire resistance. By choosing steel channels, we can create structures that are not only environmentally friendly but also safe, long-lasting, and cost-effective in the long term.

- Q: What are the different methods for connecting steel channels?

- There are several methods for connecting steel channels, including welding, bolting, and using mechanical fasteners such as screws or rivets. The choice of method depends on factors such as the structural requirements, load-bearing capacity, and the desired level of flexibility or adjustability in the connection.

- Q: Can steel channels be used for residential construction projects?

- Yes, steel channels can be used for residential construction projects. Steel channels are versatile structural components that are commonly used in the construction industry. They provide strength and stability to buildings, making them suitable for various applications, including residential construction. Steel channels are often used to support and reinforce structural elements, such as walls, roofs, and floors. They can be used as beams, columns, or purlins, depending on the specific requirements of the project. Steel channels are available in different sizes and thicknesses, allowing for flexibility in design and construction. One of the advantages of using steel channels in residential construction is their durability. Steel is a strong and long-lasting material that can withstand the test of time, ensuring the structural integrity of the building. Additionally, steel channels are resistant to fire, pests, and rot, making them a reliable choice for residential projects. Another benefit of using steel channels is their cost-effectiveness. While the initial cost of steel may be higher than other materials, such as wood or concrete, its long-term benefits, such as reduced maintenance and repair costs, make it a cost-effective option. Steel channels also require less labor and time for installation, which can further contribute to overall cost savings. Furthermore, steel channels offer design flexibility. They can be easily fabricated and customized to meet specific project requirements. This allows for efficient construction and the ability to achieve desired architectural designs. In summary, steel channels can certainly be used for residential construction projects. Their strength, durability, cost-effectiveness, and design flexibility make them a reliable choice for builders and homeowners alike.

- Q: 14 of channel steel and 12 of I-beam which force?

- Direction of forceSpecific forces can be checked by mechanical design manuals or material manualsIn the same direction, the flexural section coefficient or the moment of inertia is larger and the force is large

- Q: Can steel channels be used for mezzanine storage systems?

- Indeed, mezzanine storage systems can utilize steel channels. Owing to their robustness and longevity, steel channels are frequently employed in the construction of mezzanine floors. They offer a solid and secure foundation for bearing the load of storage items and seamlessly integrate into the overall design of the mezzanine structure. Steel channels can be tailored to meet specific needs and assembled through welding or bolting to establish a sturdy storage system. Moreover, steel channels boast corrosion resistance, rendering them suitable for enduring use in both indoor and outdoor storage settings.

- Q: What are the different cutting techniques for steel channels?

- There are several cutting techniques for steel channels, including manual cutting with a hacksaw or a cutting torch, mechanical cutting with a bandsaw or a circular saw, and CNC plasma cutting. Each technique has its advantages and is selected based on factors such as the thickness and shape of the steel channel, precision requirements, and production volume.

- Q: Standard size and price of 12# channel steel...

- 12# ordinary channel steel, high 120mm legs wide, 53mm waist thick 5,5mm, weighing 12,06 kg per meter --- (GB707-65 standard)12# light channel steel, high 120mm legs wide, 52mm waist thick 4,8mm, weighing 10,4 kg per meter ---- (YB164-63 standard)The price is about 3850 yuan / ton at presentLength 5~19 meters

- Q: What are the different load distribution techniques for steel channels in roof systems?

- Steel channels in roof systems can benefit from various load distribution techniques. These techniques play a crucial role in evenly distributing weight and forces on the channels, thus minimizing the chances of structural failure. One effective technique involves utilizing purlins, which are horizontal beams placed on top of the steel channels. These purlins offer additional support and aid in achieving a more uniform load distribution. Depending on the specific requirements of the roof system, purlins can be made from steel, wood, or other suitable materials. Another method is bridging, which entails installing vertical or diagonal braces between the steel channels. This prevents twisting or buckling under heavy loads and spreads the load over multiple channels. By doing so, the overall strength and stability of the channels are significantly enhanced. Furthermore, the spacing between the steel channels themselves plays a crucial role in load distribution. Increasing the spacing between the channels can contribute to a more even distribution of weight, reducing the concentration of load on individual channels. However, it is essential to adhere to recommended spacing guidelines to maintain the structural integrity of the system. Moreover, load-bearing walls or columns can also contribute to load distribution in roof systems. These elements provide additional support at specific points along the channels, effectively distributing the load and preventing excessive stress on individual channels. To summarize, load distribution techniques for steel channels in roof systems encompass the use of purlins, bridging, proper channel spacing, and the incorporation of load-bearing elements. These techniques work in unison to ensure an even distribution of weight and forces on the channels, minimizing the risk of structural failure and ensuring the long-term durability of the roof system.

Send your message to us

Channel Steel Galvanized Hat Furring for House, Wall, Ceiling,Purlin

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords