Ceramic Filter Plate - Ceramic Foam Filter Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

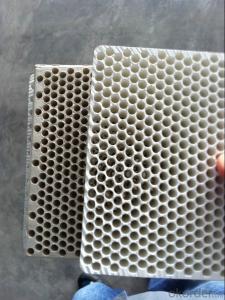

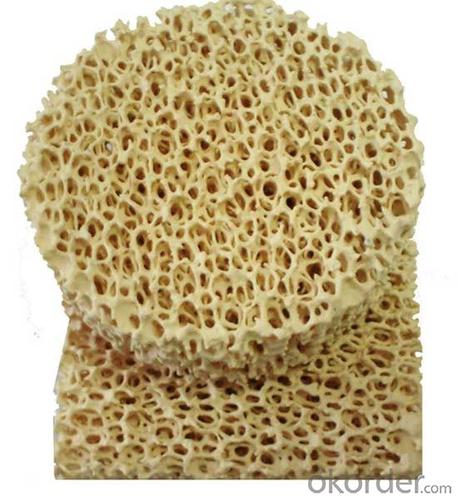

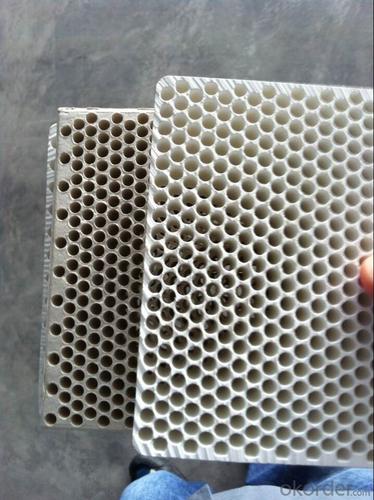

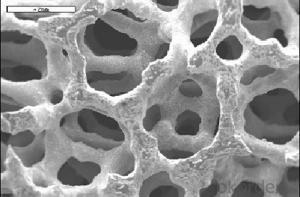

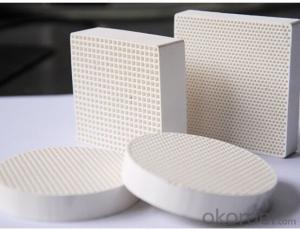

Ceramic Foam Filter

Foam Ceramic are mainly used for filtration of aluminium and aluminium alloys in foundries and cast houses . With their excellent thermal shock resistance and corrosion resistance from molten aluminum, they can effectively eliminate inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Size available:

7", 9", 12", 15", 17", 20", and 23", with porosities from PPI 10 to PPI 60(PPI ie pores per inch).

Other special sizes could be produced on request.

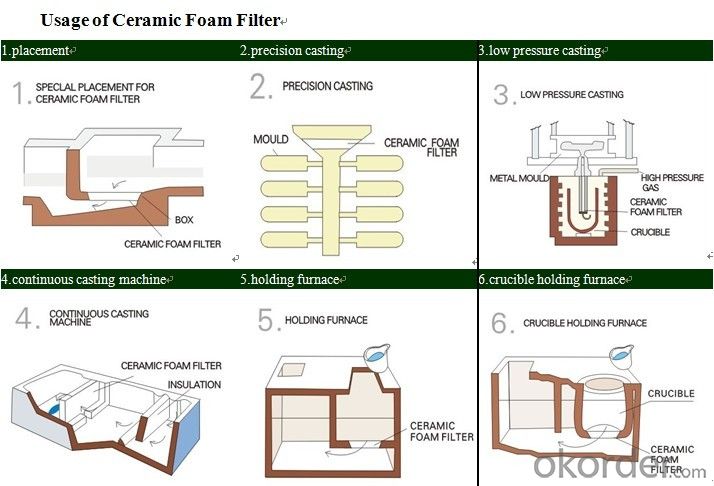

Product Applications:

Zirconia ceramic foam filters apply to purge and filter solution of carbon steel, steel alloy and stainless steel.

Product Advantages:

Reduce imparities of the castings

Improve casting quality rate

Reduce casting internal re-oxidation defects

Reduce the surface defects after machining of the castings

Precise Dimension Tolerance

High Mechanical Strength

Chemical Stability and Corrosion-resistance for molten aluminum.

Phosphate-free, No Pollution for Environment

Purifying Liquid Aluminum, Improving Quality

Reduce Defects

Reduce Cost

Increase Yield Rate

Easy to Use

Size from 40-600mm available.

Main Product Features:

Good electrical conductivity

High resistance to thermal shock

High mechanical strength

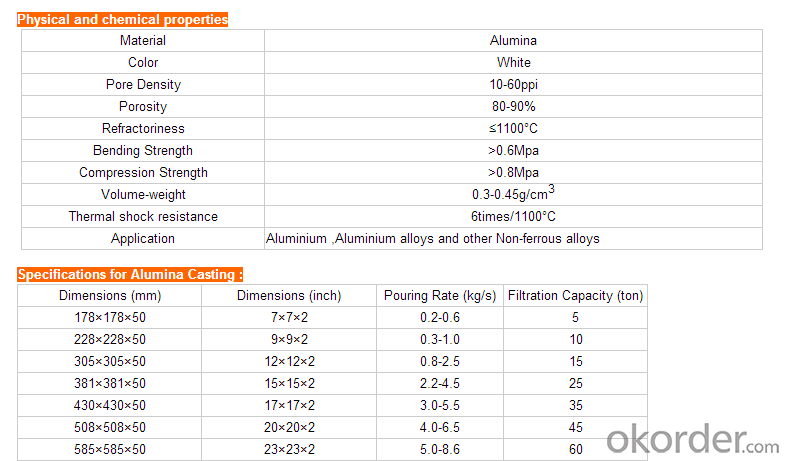

Product Specifications:

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

6. What standards do we have?

Our products meet the standards, such as ASTM, ASME, AMS, DIN, JIS etc.

The third party testing is all available for us.

Product Picture

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- The earliest filtration was mostly gravity filtration, which was followed by pressure filtration to increase the rate of filtration, followed by vacuum filtration. The drum vacuum filter invented in the early twentieth Century realized the continuous operation of the filter. Since then, various types of continuous filters have appeared. Intermittent operating filters (such as plate and frame press filters) are developed for automatic operation, and the filtration area is becoming larger and larger. In order to obtain the filter residue with low moisture content, the mechanical press filter has been developed.

- Q: Performance advantages of ceramic filter

- The base is provided with a slime recovery rotor, the rotor consists of a shaft, multistage ceramic filter disc, stripper plate, multi section water connecting pipe, pipe support plate, negative pressure connecting component dynamic disk; the rotor is in the recovery of coal slime liquid tank; the ceramic filter disc by a plurality of ceramic microporous plate cavity, located on the same axis of a ceramic plate cavity communicated through the outlet connection pipe.

- Q: What are the causes of the powder moisture in the ceramic filter?

- The ore condition has changed, such as high concentration of material, fine grain size and increase of mud content.

- Q: Why should filter core be used in backwash of ceramic filter?

- Ceramic filter recoil stage is with certain pressure of clean water from the inside out washing ceramic filter plate, the outer aperture ceramic filter plate from inside is gradually reduced, such as flushing water and unclean inside contain impurities that may block ceramic filter board, other structures in the recoil stage of pollution. Such as recoil, water is not clean, you must go through the water filter cartridge to filter again, the choice of filter core, the higher the accuracy of filtration, the more clean water, but the filter is more likely to plug, scrap. Of course, the water is clean and contains little solids. The filter core is not easy to plug and even water filters can be removed.

- Q: What's the reason for high water content in filtration copper concentrate?

- Can the cleaning of ceramic plate meet the requirement?Such as cleaning of ceramic plate is not up to the requirements, plugging holes will increase the risk of ceramic plate, ceramic plate plug serious suction effect will become worse (filter cake moisture content increased, cake thickness reduction), cleaning of ceramic plate refers to washing and cleaning.Backwash to ensure that the water filter filter water pressure in the 0.1MPa or so, at least not less than 0.07MPa or less, it is necessary to consider before the filter water pressure is low or water filter element needs to be replaced.Joint cleaning to ensure that the ultrasonic can be no trouble, every time cleaning the amount of nitric acid up to standard. If the filtration effect is not ideal, the cleaning cycle can be washed from 45--60 every 8 hours, changed to 6--7 hours and cleaned for more than 1 hours.

- Q: Why does not the iron filter of the ceramic filter work?

- You should make it clear that the filter cake has always been dry or suddenly dry, and now how much moisture? Generally, the ceramic filter is used to filter iron powder, and the water content of the filter cake is about 10%.

- Q: Can the plate filter press pass through the filter plate?

- Specific, it is necessary to choose the filter characteristics according to different materials. Plate and frame filter press: plate and frame filter press is an industrial realization of solid, liquid separation, plate and frame filter press is suspension, liquid-solid, liquid two phase, applied to chemical, ceramics, oil

- Q: Ceramic filter fineness thin mud suction is not what to do more

- With ceramic filter to treat pulp dehydration, the particle size is too large, the particles are easy to precipitate, the particle size is too small, too much mud, then the water content of the filter cake will increase, and the life of the ceramic filter plate will be reduced.

- Q: The vacuum of ceramic filter is not enough

- The vacuum degree of ceramic filter is about -0.08MPa, if the ceramic filter is less than 0.06MPa, the vacuum is not enough. If the vacuum of ceramic filter is not enough, it will influence the suction effect of ceramic filter (mainly the thickness of filter cake and water content of filter cake).

- Q: Can the ceramic plate filter the hot air?

- The vacuum degree of the ceramic filter in the vacuum system is about -0.085MPa. If the abnormal vacuum is found, the normal vacuum suction will not be available, and the suction effect will be poor, even without suction. If the vacuum is abnormal, should adhere to the vacuum pump, vacuum connection pipe is whether the fault Water Leakage leakage, distribution valve friction sealing, ceramic filter plate is connected with the rubber tube is aging or exfoliation, ceramic filter plate rupture.

Send your message to us

Ceramic Filter Plate - Ceramic Foam Filter Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords