Ceramic Filter Plate Alumina Ceramic Foam Filter for Air and Water Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Alumina Ceramic Foam Filter for Air and Water Treatment

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Material: | PU foam (polyurethane foam) | Size: | Customized | Mesh: | 10 ppi to 60 ppi |

| Property 1: | Mend structure of crystalloid | Property 2: | Reduce foreign matter | Property 3: | Stable chemical property |

| Property 4: | Stable purifying efficiency | polyurethane foam filter: | polyurethane foam |

Packaging & Delivery

| Packaging Details: | carton and pallet, or as customers' requirement |

| Delivery Detail: | 30 days after receiving the downpayment |

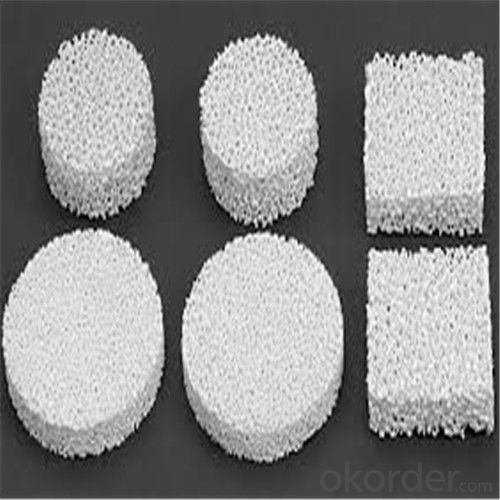

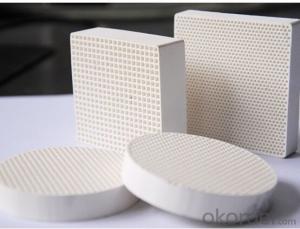

Alumina ceramic foam filter

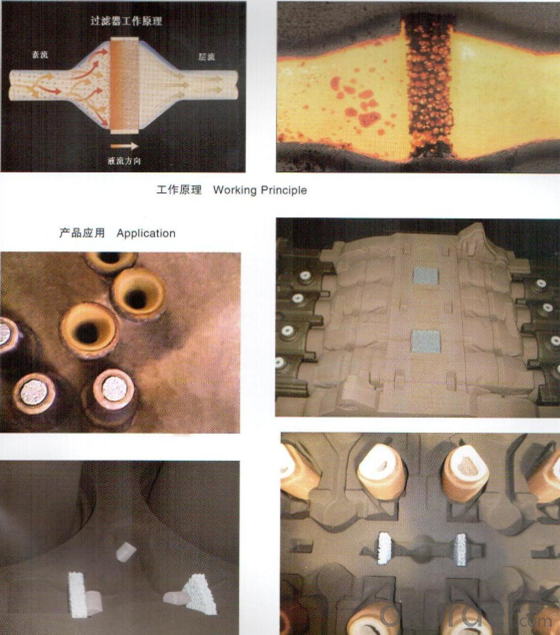

The product, adopted good portiforium foam and high purity ceramic , effectively removes non-metal solid mixture from aluminium and aluminium alloy fusant.

Specifications

Alumina ceramic foam filter

1.even aperture, high porosity, proper sinter

2.high strength of anti-flexing and anti-compression

Advantages:

even aperture, high porosity, proper sinter, high strength of anti-flexing and anti-compression, effective filtering.

It is widely applied to the aluminium fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting.

Ceramic foam filters are different from aperture specifications from 10 to 45ppi, with different sizes and shapes.

Besides the general specification ,we can offer the product according to the customers requirements.

Form A Ceramic foam filter capability

Thickness mm | Aperture PPi | Volume intensity g/cm3 | Tortuous intensity in normal temperature N/cm2

| Pressure resistence intensity in normal temperature N/cm2

| Pressure resistence intensity in high temperature N/cm2

| Refractory temperature

| Air discharging capability cm3/g

| Porosity %

|

15-100 | 10-45 | 0.35-0.45 | ≥38 | ≥80 | ≥45 | ≥1800 | ≤5 | ≥85 |

Form B 25ppi capability of typical pouring of ceramic foam filter

Specification mm | Area M2

| Maximum metal volume of pouring (kg/min) | Optimum volume of pouring (kg/min) | Typical capacity of filtering (T) |

178X178X50 | 0.0213 | 57.00 | 25-45 | 4.2 |

229X229X50 | 0.0387 | 118.00 | 35-102 | 6.9 |

305X305X50 | 0.0745 | 198.00 | 90-165 | 13.8 |

381X381X50 | 0.122 | 325.80 | 130-265 | 23.2 |

432X432X50 | 0.160 | 427.20 | 210-350 | 34.5 |

508X508X50 | 0.227 | 606.60 | 280-465 | 43.7 |

585X585X50 | 0.341 | 772.20 | 370-540 | 57.3 |

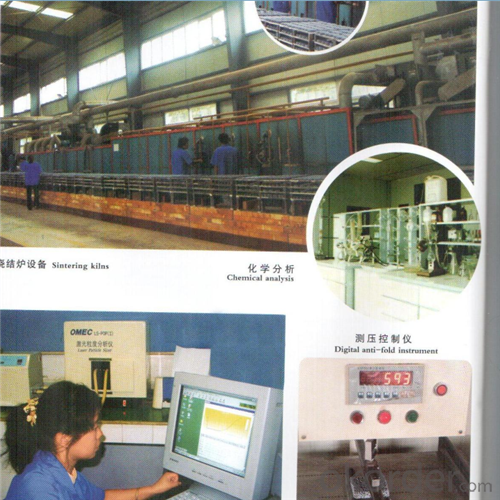

Welcome to visit our factory~

- Q: What filter material are placed in the aquarium filter?

- Submerged in water. Submersible pumps and filter cotton (often replaced by sponge) installed in one, and some brands will also be installed heaters, which become multi-purpose fish farming equipment. When working, the water is absorbed into the filter in many directions, and the filtered water is returned to the water tank by other means. This filter because of its low price and popular beginners of all ages, but the effects from the use of view, only suitable for small fish density, on the flow and filtration requirements are not high, a small aquarium, "fish" will be built in filter (especially the heating function of the filter for seedling and foster) water tank. The effect is very good. The biggest disadvantage of this device is that when it stops working, a lot of dirt stuck to the filter runs back into the water.

- Q: What happens when the pressure on the filter plate is uneven during backwashing?

- Ceramic filter is a kind of solid-liquid separation, dehydration drying equipment, such as dehydration pulp, mortar. The backwash of ceramic filter is to flush the filter medium (ceramic filter plate) with clean water with a certain pressure.

- Q: What are the materials that make up the ceramic mold?

- From the development trend of rice, the development of ceramic membrane preparation technology mainly in the following 2 aspects: one is the porous membrane research, to further improve the already commercialized inorganic ultrafiltration and microfiltration membrane, nanofiltration membrane with molecular sieve, the development function of gas separation membrane and pervaporation membrane: two in dense membrane research solid electrolyte membrane, ultra-thin metal and its alloy film and ion conduction ability is research hotspot. The commercial porous membranes are mainly ultrafiltration and microfiltration membranes, and their preparation methods are mainly particle sintering and sol-gel. The former is mainly used for making microporous filter membranes, and commercial A1203 films are prepared by particle sintering method.

- Q: The efficiency of ceramic filter is low. What's wrong with it?

- Ceramic filter is a new and efficient dehydration equipment. If users find the ceramic filter board surface suction effect is poor, or even do not suck slurry, we should promptly investigate the causes, so as not to affect production efficiency.

- Q: Why does not the iron filter of the ceramic filter work?

- The main speed of the ceramic filter is too fast.The vacuum of ceramic filter is not enough.The cleaning of ceramic filter has not met the requirement.The ceramic filter plate has a near life and a serious blockage.The selection of ceramic filter plate is different.Too much residual of ceramic scraper after discharge.

- Q: Can the plate filter press pass through the filter plate?

- There are many types of pumps to be used, such as screw pumps, slag pumps, rotary pumps, piston pumps, and diaphragm pumps.

- Q: The use of water glass as beneficiation agent, copper concentrate in the ceramic filter can not filter, how to do?

- As everyone knows, ceramic filter medium is a ceramic filter plate, microporous ceramic filter plate with a lot of distribution from the outside to the inside capillary effect, its mechanism is based on the capillary effect of microporous ceramic filter, filtration, the filtrate (generally refers to water) through these pores under the action of the vacuum suction pump, filter cake is trapped on the surface of the ceramic filter plate.

- Q: Ceramic filter capacity.

- 60 square meters of ceramic filter power 35kW or so, a high degree of automation, each class can complete the operation.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large?

- The vacuum degree of the ceramic filter is normal at about -0.08MPa. Under normal circumstances, the water content of the filter cake treated with a ceramic filter is about 10%, and the moisture content of the tail filter cake is about 15%. The water content of the filter cake increases with the increase of water content in the ceramic filter.

- Q: What's the acid of the ceramic filter plate?

- Ceramic filter automatic control system: control system through the metering pump will be concentrated nitric acid automatic mixing ceramic filter plate into nitrate after proportioning through the pipeline, so that it can be dissolved, dredge the blockage in the most microporous ceramic filter plate. This is the ceramic filter plate pickling, pickling, acid dosage should be sufficient as little pickling effect.

Send your message to us

Ceramic Filter Plate Alumina Ceramic Foam Filter for Air and Water Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords