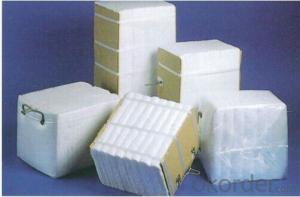

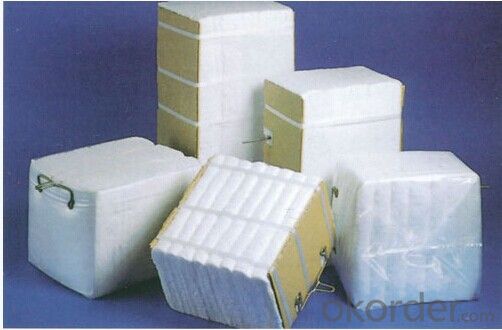

Ceramic Fiber Module for Furnace Lining

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic fiber module adopts highquality spun fiber blanket; then it is folded and compressed to certain storage. There are various anchor systems. It is a new type of refractory furnace lining products aiming at simplifying and speeding up furnace construction and improving the integrity of furnace lining. We have more than ten years export experience for ceramic fiber products.

Characteristic

low thermal capacity,low density, shorter heat up and cool down time

Low thermal conductivity , saving combustion cost in the furnace effectively

High thermal stability ,high resistance to thermal shock and airflow shock

Good mechanism strength and toughness,easy to install quickly.The anchor installed inside,excellent safety.

Type Item | ST | ||

Classification Tem.( C ) | 1260 | ||

Working TemperatureºC | 1050 | ||

Bulk Density kg/m³ | 220±15 | ||

Chemical content% | AL2O3 | 45-46 | |

AL2O3+SIO2 | 97 | ||

AL2O3+SIO2+ZrO2 | - | ||

ZrO2 | - | ||

FeO3 | <1.0 | ||

Na2O+K2O | ≤0.5 | ||

Size(mm) | 600*240-300*100-200(without anchoring parts)300*300*300(with anchoring part);According to you request |

| |

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- It should be spun from cotton, spun into spun yarn, and then joined with wire or glass fiber, and then twisted into threads to make cloth or rope

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- Hot galvanizing furnace is usually burning natural gas to the new pot heating, natural gas heating will produce higher wind speed to 21m/s, so the hot galvanized furnace insulation materials have certain requirements. The hot galvanizing furnace before 2013 is usually made of refractory bricks for heat preservation, and the energy saving effect is common.

- Q: How to install refractory fiber?

- Dry plate is used spray adhesive, mechanical compression molding, low density, has good flexibility and flexibility, generally used for insulation seal. Wet washing mold, vacuum forming board of high density, good hardness, can be processed mechanically, generally used for fire-resistant insulation.

- Q: What about the composite reflecting insulation board and ceramic fiber?

- The maximum temperature of ceramic fiber heat insulation material can be up to 1400 degrees. Although the highest use temperature of ceramic fiber is higher than that of Tianjin solid composite reflecting insulation board, the heat insulation effect is far worse.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Excellent high temperature insulation performance, long service life, corrosion resistance, aluminum, zinc and other non-ferrous metal corrosion capacity; has a good low temperature and high temperature strength;

Send your message to us

Ceramic Fiber Module for Furnace Lining

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords