High-Quality Ceramic Fiber Module for Kiln and Furnace Lining

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

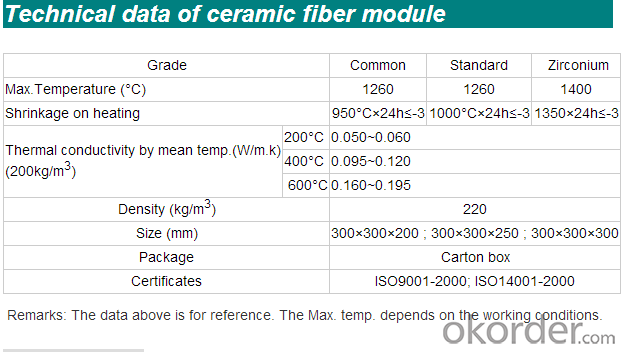

Ceramic Fiber Module of Aluminum Silicate for Linner of the Kiln and Furnace

Ceramic fiber module is made by processing the corresponding ceramic fiber needling blanket with the specific machine according to structure and size of the fiber module. During the process, it should maintain a certain percentage of compression, so as to ensure the fiber modules can swell to different directions and can crush together into a whole without crack after the lining construction. The ceramic fiber modules can be fixed on the steel plate of industrial furnace by different kinds of anchors.

Product Applications:

Ceramic Fiber Module are ideal for use in the below applications

Furnace lining and insulation of furnace in Petrochemical industry

Furnace lining and insulation of furnace in Metallurgical industry

Furnace lining and insulation of furnace in Ceramics, glass and other building materials industry

Furnace lining and insulation of heat treatment furnace in heat treatment circle

other industrial furnace lining

Product Advantages:

Excellent chemical stability

Excellent thermal stability

Excellent flexibility, the module is in pre-compression state, after the lining masonry

The Expansion of modules enable seamless lining,fiber lining can be compensated to improve

Insulation performance of Fiber lining, and the overall performance is good

Excellent thermal stability and thermal shock resistance

Ceramic fiber module can be installed quickly, and anchors set in the wall lining, which can lower the requirements of anchor Material

Main Product Features:

Excellent refractoriness

Excellent chemical stability and thermal stability

Low thermal conductivity, low thermal capacity

Resist to external mechanical forces

Able to withstand any thermal shock

Generate no gaps between modules

Product Specifications:

FAQ:

Q1.What is your MOQ?

A1 :MOQ may vary by customer's special requirement; we try our best to meet your business requirement.

Q2.Can you provide sample?

A2: Yes, we can offer sample , and some samples are free

Q3:Can you delivery by express?

A3: Yes, we can delivery by any express

Product Picture

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- Ceramic fiber can be spun, but certain auxiliary materials must be added. The ceramic fiber is soft, and the resistance and non - fiber of the ceramic fiber must be guaranteed.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- Hot galvanizing furnace is usually burning natural gas to the new pot heating, natural gas heating will produce higher wind speed to 21m/s, so the hot galvanized furnace insulation materials have certain requirements. The hot galvanizing furnace before 2013 is usually made of refractory bricks for heat preservation, and the energy saving effect is common.

- Q: How to install refractory fiber?

- Dry plate is used to spray adhesive mechanical pressing low density has good elasticity and flexibility is usually used for wet insulation sealing by washing vacuum shaping mould plate of high density, hardness, mechanical processing can be generally used as fireproof heat insulation is very good Oh, you can try

- Q: What about the composite reflecting insulation board and ceramic fiber?

- Heat insulation material with low thermal conductivity of ceramic fiber products, but this insulation material is soft material, some aspects of the use of defects. In contrast, Tianjin solid microporous nano insulation board has lower thermal conductivity.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Excellent high temperature insulation performance, long service life, corrosion resistance, aluminum, zinc and other non-ferrous metal corrosion capacity; has a good low temperature and high temperature strength;

Send your message to us

High-Quality Ceramic Fiber Module for Kiln and Furnace Lining

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches