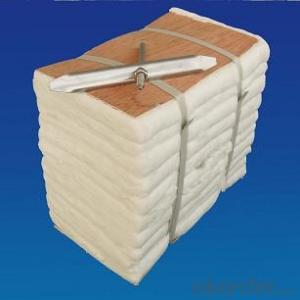

Ceramic Fiber Module - High Quality Insulation Solution

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Classification Temperature: 1050℃~1600℃

Description: Ceramic fiber module adopts highquality spun fiber blanket; then it is folded and compressed to certain storage. There are various anchor systems. The ceramic fiber module is a new type of refractory furnace lining products aiming at simplifying and speeding up furnace construction and improving the integrity of furnace lining. This product has clean and white color as well as formal dimension, which can be directly fixed on the anchor nail on steel plate for shell of industrial furnace with excellent refractory and insulating effect. Thus, it has improved the refractory and insulating integrity of furnace and pushed forward the progress of furnace construction technology.

Features:

Fast and easy installation

Lower heat storage and fuel costs

This design creates a very light lining,less steel equired

Several anchor systems

Typical applications:

Ceramic industry:

Low mass kiln cars

Continuous and batch kilns

Door linings

Glazing,porcelain furnace linings

Power generation:

Duct lining

Heat recovery

Steam system

Boiler insulation

Stack linings

Others:

Incineration equipment

Burner blocks

Induction furnace covers

Glass tempering furnace

Steel industry:

Ladle pre-heaters and covers

Heat treat furnace

Soaking pit covers and seals

Heaters and reformer lining

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- It should be spun from cotton, spun into spun yarn, and then joined with wire or glass fiber, and then twisted into threads to make cloth or rope

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- Tile blanket thickness 30mm, (2 layers of 20mm compression), hot surface layer, ceramic fiber module thickness of 300mm, total thickness of 330mm. The ceramic fiber module adopts a standard ceramic fiber module with a temperature range of 1260.Considering that the flame sprayed by the nozzle will rebound on the outer wall of the zinc pot and form a smoke wash between the furnace wall and the zinc pot wall, the wind speed is about 18m/s to 23m/s, and there is a certain corrosion. Ceramic fiber module surface brushing two times curing agent, that is resistant to corrosion, but also can resist high wind speed.

- Q: How to install refractory fiber?

- Dry plate is used spray adhesive, mechanical compression molding, low density, has good flexibility and flexibility, generally used for insulation seal. Wet washing mold, vacuum forming board of high density, good hardness, can be processed mechanically, generally used for fire-resistant insulation.

- Q: What about the composite reflecting insulation board and ceramic fiber?

- Heat insulation material with low thermal conductivity of ceramic fiber products, but this insulation material is soft material, some aspects of the use of defects. In contrast, Tianjin solid microporous nano insulation board has lower thermal conductivity.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Excellent high temperature insulation performance, long service life, corrosion resistance, aluminum, zinc and other non-ferrous metal corrosion capacity; has a good low temperature and high temperature strength;

Send your message to us

Ceramic Fiber Module - High Quality Insulation Solution

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches