Ceramic Fiber Module for Furnace Thermal Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Module

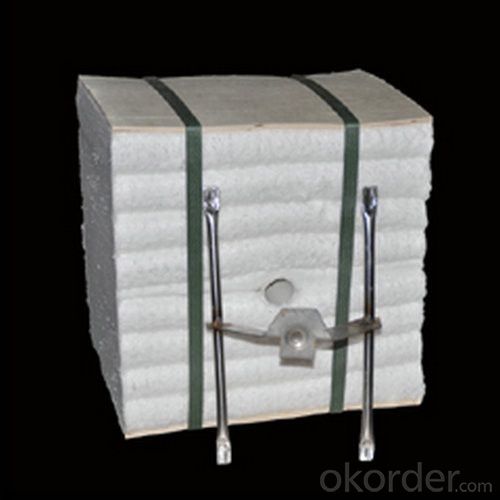

l Okorder ceramic fiber module is made from high-quality spun fiber blanket, and then folded and compressed to certain storage. Ceramic fiber module is a new type of refractory furnace lining product aimed at simplifying and speeding up furnace construction and improving the integrity of furnace lining.

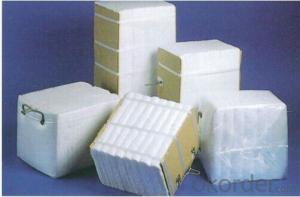

l Okorder ceramic fiber module has a nice white color and formal dimensions; they can be directly fixed on the shell of the industrial furnace. Ceramic fiber module has excellent refractory and insulating effects.

Features of Ceramic Fiber Module

Ceramic fiber module has excellent features including fast and easy installation and low heat storage, and will lower fuel costs. Ceramic fiber module improves the refractory and insulating integrity of furnaces and improves furnace construction process.

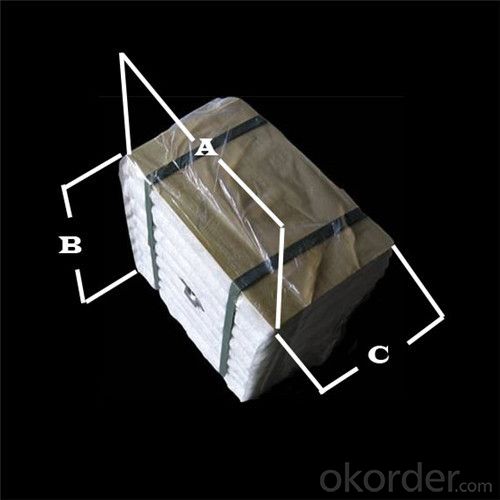

Image of Ceramic Fiber Module

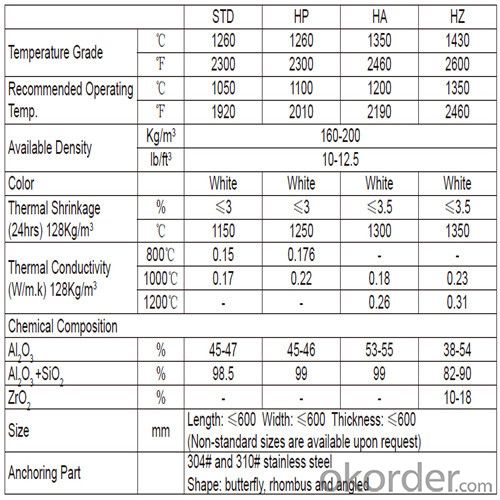

Technical Data of Ceramic Fiber Module

Application of Ceramic Fiber Module

Petrochemical process heater

Heat treating furnace

Cement rotary kiln

Glass melting tank

Ceramic firing kiln

Backup insulation

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- Ceramic fiber can be spun, but certain auxiliary materials must be added. The ceramic fiber is soft, and the resistance and non - fiber of the ceramic fiber must be guaranteed.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

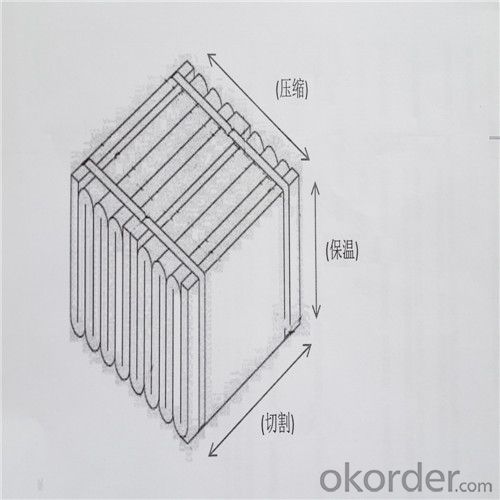

- The arrangement mode of the ceramic fiber module adopts "soldier row type" - along the module compression size. Fiber module arrangement using ceramic fiber blanket folded thickness after 20mm compression, and the use of "U" type nail to keep the 500~700mm distance to the fiber module fixed to insert compensation fiber expansion surface may produce contraction, the structure can avoid the "parquet" arrangement, fiber module for the corner site the expansion caused by uneven phenomenon, "playboy" has the best effect of adiabatic. When the back lining of the furnace top is installed, the quick card matching module is used for temporary fixing with bolts.

- Q: How to install refractory fiber?

- Good chemical stability; good thermal stability; excellent elasticity, ceramic fiber module is pre pressed state, in lining up after the expansion of ceramic fiber module to enable seamless lining, and can compensate for fiber lining contraction, in order to improve the insulation performance of fiber lining, the overall performance is good; excellent thermal stability and thermal shock resistance the ceramic fiber module; quick installation, and anchors set in the wall lining noodles, can reduce the anchor material requirements.

- Q: What about the composite reflecting insulation board and ceramic fiber?

- Heat insulation material with low thermal conductivity of ceramic fiber products, but this insulation material is soft material, some aspects of the use of defects. In contrast, Tianjin solid microporous nano insulation board has lower thermal conductivity.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Excellent high temperature insulation performance, long service life, corrosion resistance, aluminum, zinc and other non-ferrous metal corrosion capacity; has a good low temperature and high temperature strength;

Send your message to us

Ceramic Fiber Module for Furnace Thermal Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords