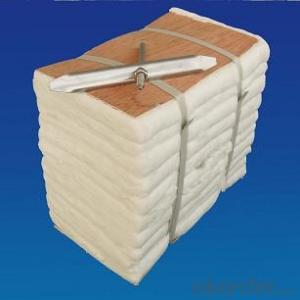

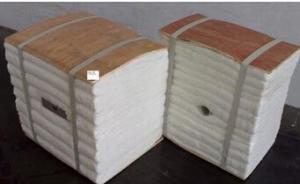

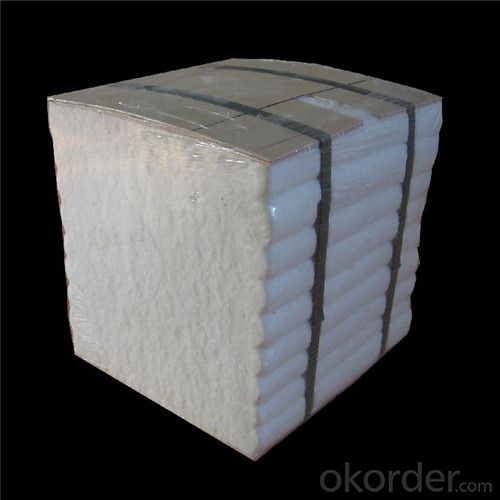

Ceramic Fiber Module for Kiln and Furnace Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Aluminum Silicate Ceramic Fiber Module For Linner Of The Kiln And Furnace

| Application: | Liners Of Industrial Furnace | Grade: | HZ (High Zirconium) | Ultimate Strength (≥ MPa): | 0.65 |

| Working Temperature: | 1000~1600 | Fiber Diameter: | 5μm | Thermal Conductivity: | 0.2 |

| Shrinkage (1800℉, 3h): | 1.3 | Place of Origin: | China (Mainland) | Model Number: | |

| Brand Name: | Ceramic Fiber Module Grade:: | HA (High Aluminum) | Ceramic Fiber Module Density (kg/m³ ):: | 160 | |

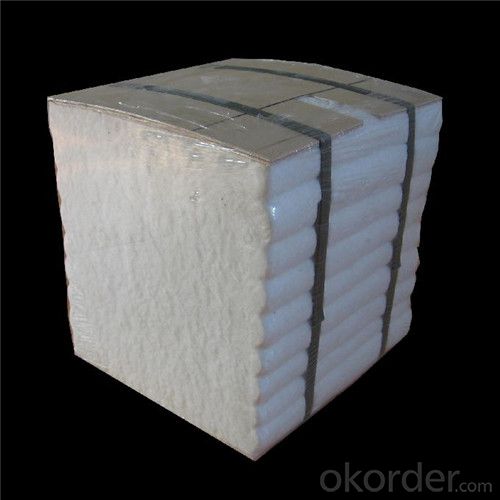

| Ceramic Fiber Module Dimensions:: | 300*300*(50, 75) | Ceramic Fiber Module Brand: | YH | Ceramic Fiber Module color:: | white |

| Ceramic Fiber Module Shrinkage: | 1.3 | Ceramic Fiber Module Diameter:: | 5μm |

Packaging & Delivery

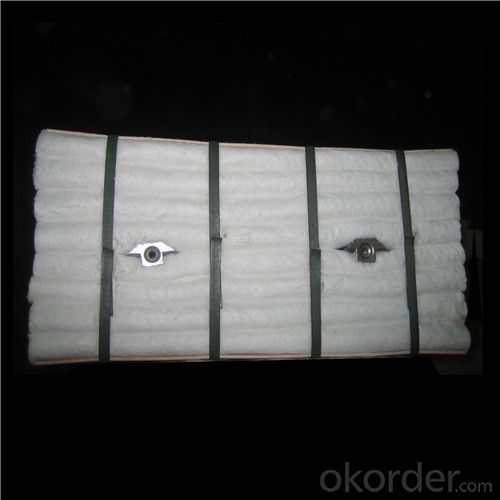

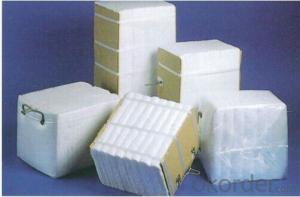

| Packaging Details: | carton bags with plastic woven bags inside or according to the customer's requirement |

| Delivery Detail: | within two weeks |

Specifications

1260working temperature

easy to fold

Density: 220kg/m3

Size: 300*300*300mm

Ceramic fiber module is made by processing the corresponding ceramic fiber needling blanket with the specific machine according to structure and size of the fiber module. During the process, it should maintain a certain percentage of compression, so as to ensure the fiber modules can swell to different directions and can crush together into a whole without crack after the lining construction. The ceramic fiber modules can be fixed on the steel plate of industrial furnace by different kinds of anchors.

Characteristics

Excellent chemical stability and heat stability

Low heat conductivity, low thermal capacity

The anchors fixed on the back of the modules can make the installation of the modules in soldiers’ ranks way and block floor way.

Folding blanket will crush together in different directions after untie them, so the modules have no crack.

Elastic fiber blanket can resist the mechanical external force, and the elasticity can make up the deformation of the furnace jacket, which can avoid the crack between modules.

Because of the light weight, as thermal insulation material, the absorption of heat is low, so the low heat conductivity can make excellent energy saving effect, which can also resist any thermal shock.

The lining has no need of dry or maintenance, so it can come into use as installation.

The anchor system is not close to the hot side of the modules, so the anchors are staying in a comparative low temperature environment.

1260 Fiber Folding Block | 1400 Fiber Folding Block | 1260 Fiber Folding Block | 1400 Fiber Folding Block | |

Classification Temperature(°C) | 1260 | 1400 | 1260 | 1400 |

Density(Kg/m3) | 160, 190, 220 | |||

Heating Linear Shrinkage (%) | (1100°C*24hrs) 1.0 | (1200°C*24hrs) 1.1 | (1100°C*24hrs) 1.0 | (1200°C*24hrs) 1.1 |

Heat Conductivity Kcal/mh °C (W/m·k), ASTM C201 160kg/m3 | ||||

Average 400°C | 0.09 | 0.09 | ||

Average 600°C | 0.14 | 0.14 | 0.14 | 0.14 |

Average 800°C | 0.21 | 0.21 | 0.20 | 0.20 |

Average 1000°C | 0.26 | 0.28 | ||

Module Size (mm/module) | 300*300*150, 200, 250, 300 | |||

1260 Fiber Veneer Block | 1400 Fiber Veneer Block | 1500 Fiber Veneer Block | 1600 Fiber Veneer Block | |

Classification Temperature(°C) | 1260 | 1400 | 1500 | 1600 |

Density(Kg/m3) | 130, 160 | |||

Heating Linear Shrinkage (%) | (1100°C*24hrs) 1.3 | (1200°C*24hrs) 1.5 | (1300°C*24hrs) 1.2 | (1400°C*24hrs) 1.1 |

Heat Conductivity Kcal/mh °C (W/m·k), ASTM C201 160kg/m3 | ||||

Average 400°C | 0.12 | |||

Average 600°C | 0.17 | 0.12 | 0.10 | |

Average 800°C | 0.25 | 0.16 | 0.14 | |

Average 1000°C | 0.21 | 0.19 | ||

Module Size (mm/module) | 300*300*50, 75 | |||

Note:

The technical data is the average value based on the test standard, so they are changeable within limits, but not absolute guarantee value

FAQ:

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a general idea of the specification and technical data of your products?

Yes, catalog is on your request.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- Yes, only the machines require more special

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- Tile blanket thickness 30mm, (2 layers of 20mm compression), hot surface layer, ceramic fiber module thickness of 300mm, total thickness of 330mm. The ceramic fiber module adopts a standard ceramic fiber module with a temperature range of 1260.Considering that the flame sprayed by the nozzle will rebound on the outer wall of the zinc pot and form a smoke wash between the furnace wall and the zinc pot wall, the wind speed is about 18m/s to 23m/s, and there is a certain corrosion. Ceramic fiber module surface brushing two times curing agent, that is resistant to corrosion, but also can resist high wind speed.

- Q: How to install refractory fiber?

- Dry plate is used to spray adhesive mechanical pressing low density has good elasticity and flexibility is usually used for wet insulation sealing by washing vacuum shaping mould plate of high density, hardness, mechanical processing can be generally used as fireproof heat insulation is very good Oh, you can try

- Q: What about the composite reflecting insulation board and ceramic fiber?

- The maximum temperature of ceramic fiber heat insulation material can be up to 1400 degrees. Although the highest use temperature of ceramic fiber is higher than that of Tianjin solid composite reflecting insulation board, the heat insulation effect is far worse.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Excellent high temperature insulation performance, long service life, corrosion resistance, aluminum, zinc and other non-ferrous metal corrosion capacity; has a good low temperature and high temperature strength;

Send your message to us

Ceramic Fiber Module for Kiln and Furnace Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches