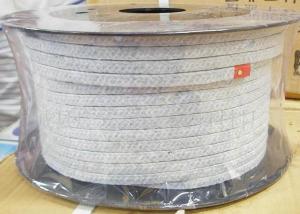

Ceramic Fiber Textiles Square Braid Rope

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 40 Rolls kg

- Supply Capability:

- 10 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Square Rope

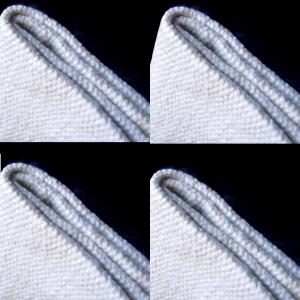

Ceramic fiber square ropes are made of high quality ceramic fiber yarn. The ropes normally contain 16 to 20% rayon fiber which will burn out at high temperature, but has no effect on the properties of the products. Ceramic fiber square ropes can be used for high temperature applications up to 2300 F. It contains a certain amount of binder material which is normally burned at lower temperature and does not affect the insulation property.

High performance ceramic fiber material fabricated from E-glass or chrome-nickel steel wire inserted ceramic fiber yarn which is braided around a core of ceramic fiber cord to form a packing in round section.

Features of Ceramic Fiber Square Rope

Excellent high temperature stability.

Excellent chemical stability resistance

Excellent thermal electrical insulation

Low heat storage

Excellent chemical stability

Excellent thermal shock resistance

Excellent sound absorptio

Application of Ceramic Fiber Square Rope

Radiant tube packing for heat- treated furnaces

Expansion joint packing

Seals for stoves and ovens

Bulb in tadpole gaskets, wick for oil burning apparatus, fireproof wrap and insulation

Covering Material for fireproofing cable, cloth, high temperature expanding material

We has success in its ceramic fiber square rope products due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber square rope application and would like to assist you in product selection, system design, and installation techniques.

Packing of Ceramic Fiber Square Braid Rope

Package could be woven bags or carton box as per buyer's request and quantity.

Technical Data of Ceramic Fiber Square Braid Rope

|

|

CERAMIC FIBER TEXTILES | |

|

|

Classification Temperature (℃) | 1260 |

|

|

Melting Point (℃) | 1760 |

|

|

Temperature Limit of Insert | Glass 650℃ |

Stainless Steel 1100℃ | |

|

|

Color | White |

|

|

Fiber Diameter (µm) | 3-4 |

|

|

Loss on Ignition (%) | 18 |

|

|

Thermal Conductivity(W/m.k) 1000℃ | <0.18 |

|

|

Linear Shrinkage 24hrs (%) 1100℃ | 3 |

|

|

Chemical Composition (%) |

|

|

|

Al2O3 | 47-49 |

|

|

Al2O3+ SiO2 | 99 |

|

|

Fe2O3 | 0.2 |

|

|

K2O+Na2O | 0.2 |

- Q: Is aluminum silicate fiber completely insulated from heat transfer?

- Aluminum silicate fiber module in the well sealed at the same time, the thickness of heat insulation protection cases, can be isolated from the transfer of hot air to the maximum, complete isolation is not possible, the total fiber trolley furnace as an example, long-term use temperature of one thousand degrees, in addition to the door is sealed by the ceramic fiber packing do seal

- Q: What is the function of (ceramic) ceramic powder?

- Opaque porcelain: cover the color of the base crown and increase the retentionNeck edge porcelain: also called neck porcelain, darker color, showing neck colorBody porcelain: also called dentin porcelain, the main porcelain powder, used to obtain the natural beauty of dentinEnamel porcelain: also called cut end porcelain, used for cutting ends, translucencyTransparent porcelain: reflects the natural and transparent shape of teethGlaze powder: colorless and transparent, simulating the luster of enamelThere are modified porcelain, dyed porcelain, gums, porcelain and so on, can show different colors and special restoration needs.

- Q: Is everybody's ceramic fiber cloth poisonous?

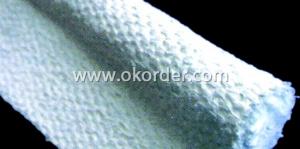

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..

- Q: Can ceramic fibers be spun?

- The utility model can also achieve higher strength by increasing metal wire reinforcement, and finally can be made into products such as yarn, cloth, belt, rope, packing, etc., and the utility model has wide application.

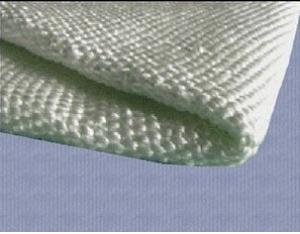

- Q: What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- High temperature ceramic fiber cloth is made of ceramic fiber cotton, E-glass filament, high temperature resistant stainless steel alloy wire with a special process, high strength, good flexibility, high machinability, not only has high temperature heat insulation performance, has the flexibility of common textiles.

- Q: What are the differences between digital textile printing ink and printing ink?

- 3. acid ink:Suitable for jet printing of silk, wool and nylon;4. coating ink:Suitable for direct printing of all textiles.

- Q: What are the man-made fibers polluting the environment?

- [] is a man-made fiber synthetic fiber as raw materials by using natural polymer cellulose or protein compounds in nature (such as wood, cotton, rice straw, bagasse fiber or milk, soybean, peanut protein, etc.) through a series of chemical and mechanical processing and made of cotton, wool and silk as similar to the textile fiber. Such as artificial cotton, rayon and so on.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper

- Ceramic fiber paper and ceramic fiber cloth are refractory insulation materials, which can be used for insulation and heat preservation

- Q: Which is better, ceramic fiber or spray velvet?

- Different applications of two kinds of ceramic fiber cotton:In 1, production of HLGX ceramic fiber module: rejection due to thick and long silk fiber is better than spraying silk carpet, in the block made of the folding process, blowing fiber blankets easily broken and torn, and thrown silk fiber blanket can be folded very closely and not easy to damage, the quality will directly affect the block lining quality;The vertical layer 2, large boiler insulation blanket shop carpet fiber application: rejection due to long and thick, has better tensile resistance, more durable, so the rejection is better than spray carpet carpet;3, application of ceramic fiber textile, silk fiber thick and long and has good spinnability, the ceramic fiber thrown silk became the production of ceramic fiber textiles (cloth, tape, rope, pipe and other special materials);

- Q: Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Acrylic may sound strange, because it is a new word that has appeared on the mainland in the last two years. It was not until 2002 that the advertising industry, furniture industry and handicraft industry were gradually understood by a few. "Acrylic" is a transliteration of foreign words, English is ACRYLIC, it is a chemical material. The chemical name is called "PMMA", which belongs to propylene alcohol, commonly known as "specially treated organic glass". In the application industry, its raw materials usually appear in the form of particles, plates, pipes and so on.

Send your message to us

Ceramic Fiber Textiles Square Braid Rope

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 40 Rolls kg

- Supply Capability:

- 10 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords