Ceiling Profile Drywall Stud and Track Profiles for Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Our series products main supply to Middle East.

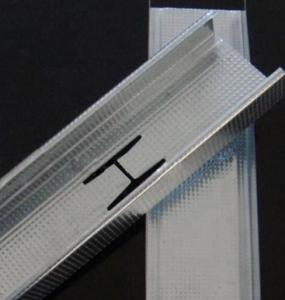

C-Channel 38*12,50*15

Furring channela 68*35*22

Stud 41*35, 50*35, 63*35, 70*32, 70*34.5, 75*35, 100*35

Track 41*25, 50*25, 63*25, 72*25, 75*25, 100*25

Angle 25*25, 30*30

Our series products main supply to Russian.

CD60*27

UD28*27

CW50*50, 75*50, 100*50

UW50*40, 75*40, 100*40

Our series products main supply to Australia, New Zealand.

Top Cross Rail 25*21

Furring channel 28*38, 16*38

Furring channel track 28*20*30,16*20*30

Stud 51*33.5*35.5,64*33.5*35.5, 76*33.5*35.5, 92*33.5*35.5, 150*33.5*35.5

Track 51*32*32, 64*32*32, 76*32*32, 92*32*32, 150*32*32

Length and thickness can be customized as customers request

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

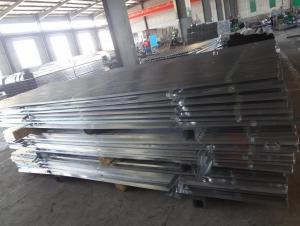

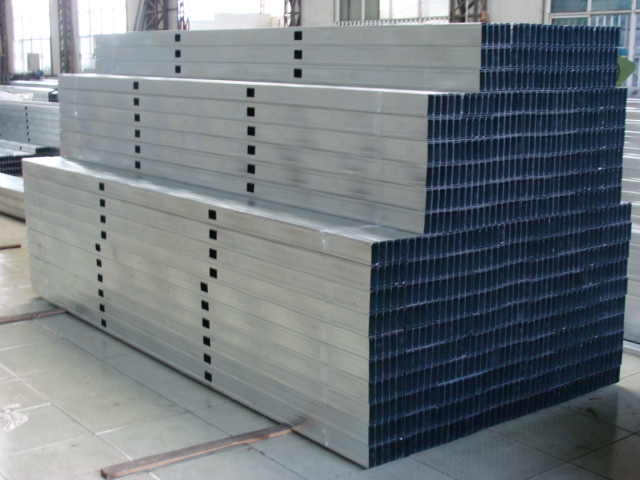

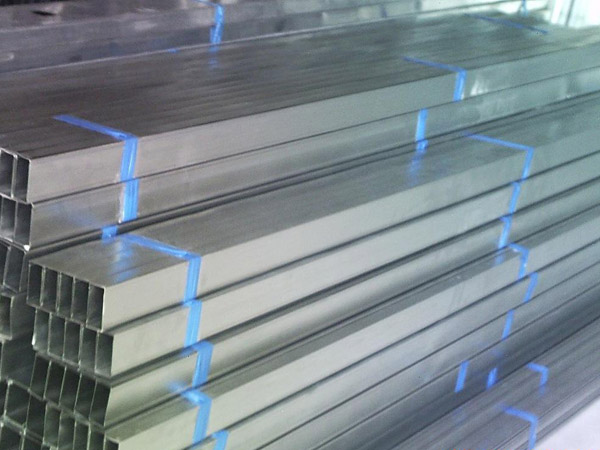

Pictures

- Q: Light steel keel ceiling construction some of my hair

- The best on the network to find it

- Q: Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- The effect of the two ceiling is the same, but the material is different, light steel keel price is relatively cheap, the best light steel keel material with accessories per square price of not more than 15 yuan, detailed specifications, the unit price is as follows: 1.0 main keel each Square 2 5,0.5 pairs of keel 8 per square, boom diameter 8MM 1 2, accessories 2 per square, loss plus a little on the line This ratio is limited to flat top, and only to the building materials market, light steel keel store to have such a price Oh, the decoration company fucking offer to turn several times, not just a little bit high, be careful slaughtered. Gypsum board made of the dragon card is good, imported brands are Lafarge, Jieke, can be resistant, more than 20 dollars a count down every square as long as 10 less than How can it be professional? The The

- Q: Home ceiling with green steel skeleton or wooden frame

- Of course with a wooden frame

- Q: Tectonic hierarchy of light steel keel

- Operating conditions 1. Construction of the structure should be in the cast-in-place concrete floor or prefabricated concrete floor slab, according to the requirements of the radio, according to the embedded φ6 ~ φ10 reinforced mixed boom, shot without the requirements of the arrangement of large keel location embedded steel hanging Rod, the general spacing of why 900 ~ 1200mm. 2. When the wall of the ceiling room for the brick masonry, the elevation should be in the ceiling along the walls and columns around the masonry embedded wood preservative, along the wall spacing 900 ~ 1200mm, the column should not be buried on each side More than two pieces of wood. 3. Install the roof of the various pipelines and ventilation ducts, to determine the light, ventilation and a variety of exposed mouth position. 4. All kinds of materials all ready to prepare. 5. Ceiling cover panel should be installed before the wall, wet operation project. 6. Take the roof construction platform. 7. Light steel skeleton roof in a large area before the construction, should do the model between the roof of the crown, lamp, vents of the tectonic treatment, block and fixed methods should be tested and approved by the approved before the big Area construction.

- Q: 140 square meters light steel keel double gypsum board ceiling fee, material costs about how much money

- The general cost of about 4,000 materials, first-line brand of materials costs around 7000, labor costs about 3000-4500 between ...

- Q: PVC plastic buckle plate ceiling with what keel ah?

- Plastic buckle, it should be wooden keel, is the wooden side. If it is aluminum buckle, it should be light steel keel.

- Q: Light steel keel second ceiling

- Secondary ceiling local use of wood core board structure, hanging hanging wooden core board structure can do two ceiling.

- Q: Light steel keel moisture-proof gypsum board ceiling which is the grass-roots which is the surface layer?

- Nice, smooth, neat positive

- Q: Play light steel keel cut off how not to damage the ceiling

- Can be found after the next day keel fixed, the other side can be used to do vertical keel shape, and then package edge

- Q: Wood keel and light steel keel were used for where?

- Wood keel is generally used in the living room and aisle ceiling, light steel keel used in the kitchen bathroom ceiling

Send your message to us

Ceiling Profile Drywall Stud and Track Profiles for Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords