Aluminum AA3003 Mill Finished Circles - CC Quality Cookware Grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

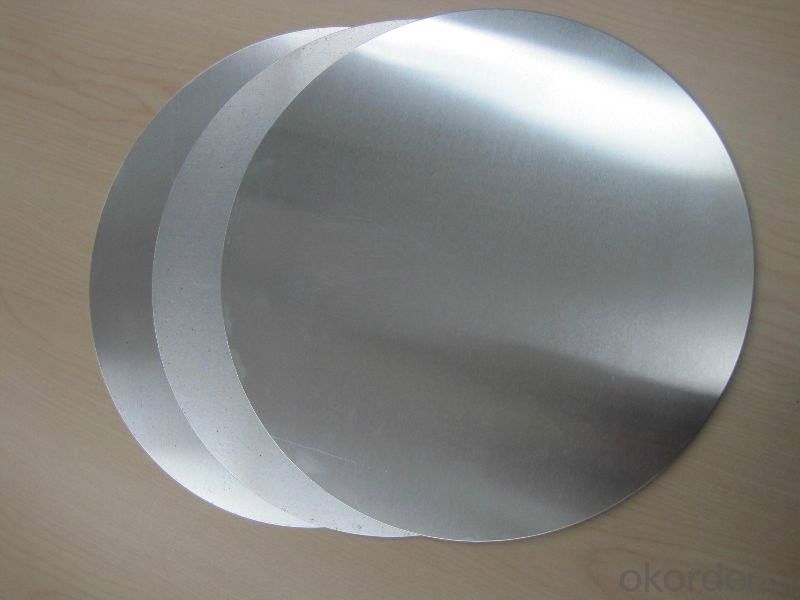

1.Structure of CC Quality AA3003 Mill Finished Aluminum Circles Used for Cookware Description

CC Quality AA3003 Mill Finished Aluminum Circles Used for Cookware is made from aluminum coils 1xxx. CC Quality AA3003 Mill Finished Aluminum Circles Used for Cookware has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

CC Quality AA3003 Mill Finished Aluminum Circles Used for Cookware are widely used for kitchen wares including fried pans, non-sticky pans, cooking pots,hard anodized cookware, pressure cooker and house hold utensils.

2.Main Features ofCC Quality AA3003 Mill Finished Aluminum Circles Used for Cookware

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.CC Quality AA3003 Mill Finished Aluminum Circles Used for Cookware Images

4.CC Quality AA3003 Mill Finished Aluminum Circles Used for Cookware Specification

Alloy | AA3003 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of CC Quality AA3003 Mill Finished Aluminum Circles Used for Cookware

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test CC Quality AA3003 Mill Finished Aluminum Circles Used for Cookware.

B.When will you deliver the products?

CC Quality AA3003 Mill Finished Aluminum Circles Used for Cookware will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: This question asks for methods to effectively clean aluminum surfaces without causing damage.

- <p>To clean aluminum surfaces effectively, use a mild detergent and warm water. Mix a few drops of dish soap with water in a bucket. Dip a soft cloth or sponge into the solution and gently wipe the aluminum surface. Avoid using abrasive materials or harsh chemicals, as they can scratch the surface. After cleaning, rinse with water and dry thoroughly to prevent water spots. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. Regular cleaning will help maintain the surface's appearance and prevent corrosion.</p>

- Q: This question asks about the methods used to measure the purity of aluminum.

- <p>The purity of aluminum can be determined through various analytical techniques. One common method is spectroscopic analysis, which includes techniques like atomic absorption spectroscopy (AAS) and inductively coupled plasma mass spectrometry (ICP-MS). These methods can detect trace elements in aluminum, providing a measure of its purity. Another method is gravimetric analysis, where impurities are chemically separated and weighed to determine their concentration. X-ray fluorescence (XRF) is also used for non-destructive testing of aluminum purity. Each method has its advantages and limitations, and the choice depends on the required level of accuracy and the specific impurities of interest.</p>

- Q: Is it possible to create jewelry using pure aluminum?

- <p>Yes, pure aluminum can be used to make jewelry, but it's not commonly used for fine jewelry due to its lower value and potential for oxidation. While it is lightweight and affordable, it lacks the luster and durability of precious metals like gold, silver, or platinum. Aluminum can tarnish and may cause allergic reactions in some individuals. It is more commonly used in costume jewelry or for specific designs where its properties are advantageous.</p>

- Q: How can we improve the efficiency and effectiveness of aluminum recycling?

- <p>Yes, there are several ways to recycle aluminum more efficiently and effectively. First, increase consumer awareness about the benefits of recycling aluminum and the importance of proper sorting. Second, invest in advanced recycling technologies that can process aluminum more quickly and with less waste. Third, collaborate with manufacturers to design products that are easier to recycle and made from more recycled content. Lastly, improve collection systems to ensure a higher percentage of aluminum waste is captured and recycled. These steps can significantly boost aluminum recycling rates and sustainability.</p>

- Q: This question asks for methods to prevent aluminum from seeping into food when cooking with aluminum cookware.

- <p>To prevent aluminum from leaching into food when using aluminum cookware, follow these guidelines: Avoid using aluminum cookware for acidic foods or beverages, as acids can cause aluminum to leach. Do not cook with high heat, as this can increase the risk of leaching. Use a protective coating, such as a non-stick coating or a thin layer of oil, to create a barrier between the food and the aluminum. Regularly replace or repair any damaged cookware to prevent exposure to bare aluminum. Finally, consider using alternative cookware materials, such as stainless steel or cast iron, for long-term cooking and storage.</p>

- Q: Is it possible to use aluminum foil as a substitute for a non-stick surface when cooking eggs in a frying pan?

- <p>While it is technically possible to use aluminum foil to cook eggs in a frying pan, it is not recommended. Aluminum foil can stick to the eggs and make them difficult to remove without breaking. Additionally, aluminum foil can tear or puncture easily, leading to hot oil spills and potential safety hazards. It's better to use a non-stick pan or a well-seasoned cast iron pan for cooking eggs to ensure easy release and even cooking.</p>

- Q: This question asks about the impact of adding magnesium to aluminum alloys and how it changes their characteristics.

- <p>The addition of magnesium to aluminum alloys significantly improves their mechanical properties, particularly strength and rigidity. Magnesium enhances the alloy's resistance to corrosion and increases its formability. It also contributes to better weldability and reduces the likelihood of hot cracking during the welding process. However, the addition of magnesium can also lead to a decrease in electrical conductivity and may increase the alloy's susceptibility to stress corrosion cracking. The overall effect of magnesium on aluminum alloys is to create a material that is lighter, stronger, and more resistant to environmental degradation, making it suitable for various applications in the aerospace, automotive, and construction industries.</p>

- Q: What are the differences between Aluminum Oxide and Aluminum Alloy in terms of their properties and applications?

- <p>Aluminum Oxide and Aluminum Alloy are distinct materials with different properties and uses. Aluminum Oxide, also known as alumina, is a ceramic material with a high melting point, hardness, and electrical insulation properties. It's used in abrasives, electronics, and as a refractory material. In contrast, Aluminum Alloys are composites of aluminum with other elements like copper, magnesium, or silicon, which enhance their strength, corrosion resistance, and malleability. They are widely used in construction, automotive, aerospace, and packaging due to their lightweight and durability.</p>

- Q: What are the various applications of aluminum in the construction industry?

- <p>Aluminum is widely used in construction due to its lightweight, durability, and resistance to corrosion. It is utilized in the manufacturing of window frames, doors, roofing, and facades for its strength and low maintenance requirements. Aluminum is also used in structural components such as beams and columns, and in the construction of bridges and high-rise buildings. Its malleability allows for easy shaping and forming, making it ideal for intricate designs. Additionally, aluminum's thermal conductivity and reflectivity make it suitable for energy-efficient construction.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum in the construction of solar panels.

- <p>Aluminum offers several advantages in solar panel construction, such as its lightweight nature, which reduces the overall weight of the panels and makes them easier to install. It is also highly conductive, enhancing the efficiency of electricity generation. Additionally, aluminum is corrosion-resistant and durable, which means it can withstand harsh weather conditions and last longer. However, there are disadvantages, such as its relatively low strength compared to other metals, which could lead to damage under high stress. Aluminum also has a higher reflectivity, which can reduce the amount of sunlight absorbed by the solar cells. Lastly, while aluminum is abundant, its extraction and processing can have environmental impacts, contributing to carbon emissions and resource depletion.</p>

Send your message to us

Aluminum AA3003 Mill Finished Circles - CC Quality Cookware Grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches