Aluminum Mill Finished Circle for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

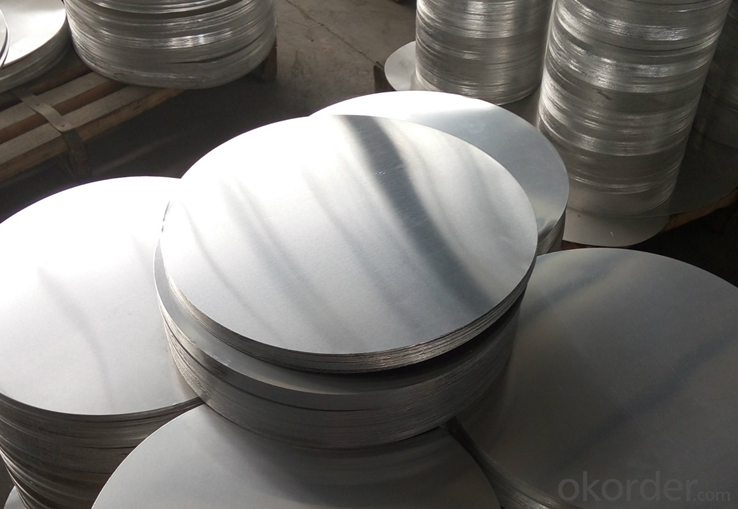

Mill finished Aluminum Circle for Cookware

Specifications

Alloy | AA1050,AA1060,AA1100 AA3003etc. |

Temper | O,H14 |

Thickness | 0.5MM-4MM |

Diagonal | 100-1200MM |

Standard | GB/T 3880-2006 |

The villa with Mediterranean style omits the heavy and complicated sculptures and decorations. It makes people feel that they would recover their original simplicity, and feel that the building is so distinctive, through the simple architectural lines and the perfectly round trimming. The design with the asymmetry features is full of romantic passion in the sunshine.

Housing and Building All the components of the Housing and Building are prefabricated in the manner of factory standardized production, and then assembled on-site, by which the construction mode of component prefabrication and on-site assembly can be realized. Characterized by no wet operation, short construction period, reduction of noise, dust and waste, small impact by climate conditions, easy disassembly and recycling, it is consistent with the requirements on energy conservation and environmental protection of green buildings.

Features:

• High manufacturing accuracy

• Smooth surface

• No waves

• High strength of extension and yield

• Well packaged

Application:

It is used in cookware, engineering, lighting purpose, fried pans, non-sticky pans, cooking pots, kettles, hard anodize cook wire, pressure cooker and house hold utensils, reflector of the light, etc

Benefit:

1. Thermal Insulation

The advanced exterior overall thermal insulation meets the updated state energy-saving standards for buildings. It refrains from the cold and thermal bridges phenomenon, and keeps buildings away from damages such as dampness, distortion, mildew and corrosion.

The unique heat reflection and ventilation layer design can make better insulation effects. Temperature can be reduced by five to eight degrees.

2. Seismic and Wind Resistance

Withstand the shock of 9 on the Richter scale.

The dense light gauge steel and column are connected in flexible method with screws and bolts, which can absorb the energy of earthquake. There are fittings between foundation and wall, which are resistant to pull out and shear. The total weight of the house is light, which is only 1/6 of traditional concrete houses. Therefore it has better anti-seismic performance.

Can endure typhoon of 12 levels

There are special fittings among roof, floor, wall and basement. The strong connection can help resist typhoon of 12 levels.

3. Roof Load-bearing and Fireproof

The roof can withstand 1500mm thickness snow.

The structure can be designed according to climate requirements.

Low-rise building fire resistance meet 2.5h (Grade Ⅱ) design standard.

High-rise building fire resistance meet 3h (Grade Ⅰ) design standard.

Wall and floor slab use special technology which can meet 3h refractory limit.

4. Sound Insulation

Improved technology on sound insulation and shock absorption meet the state building standards for sound insulation. Special methods are performed, especially towards the audio frequency ranging from 250 to 1000 Hz which is the most sensitive to ears, in order to create a quiet and comfortable living environment.

5. Moisture-proof and Ventilation

There is a gap between wall and roof truss, so the air can flow inside.

There is a one-way ventilation layer in the composite wall, which is able to make the wall ‘breathing’. This means moisture can be reduced inside of the door.

6. Durable

90 years structure safety guarantee

Special coating technology enables the structural materials to have the self-restoration function to prevent rust and corrosion.

Envelope materials using new lightweight building materials to achieve fire resistant,anti-corrosion and anti-moth.

7. Energy Efficient and Environmental Protection

FAQ:

1.How about the installation? For example, the time and cost?

To install 200sqm house needs only 45 days by 6 professional workers. The salary of enginner is USD150/day, and for workers, it's 100/day.

2.How long is the life span of the house?

Around 50 years

3. And what about the loading quantity?

One 40'container can load 140sqm of house.

Images:

- Q: What other applications can aluminum be utilized for in the manufacturing industry besides common uses?

- <p>Aluminum has a wide range of alternative uses in manufacturing due to its lightweight, corrosion resistance, and strength. It is used in the automotive industry for car parts to reduce weight and improve fuel efficiency. In aerospace, aluminum is crucial for aircraft construction due to its strength-to-weight ratio. It's also used in the construction of buildings for window frames, roofing, and facades. In the packaging industry, aluminum is used for food and beverage cans, as well as pharmaceutical blister packs. Additionally, aluminum is utilized in electrical components like wiring and transformers due to its excellent conductivity. It's also found in various consumer goods, such as bicycles, sports equipment, and electronic devices.</p>

- Q: This question asks for the benefits or positive attributes that aluminum has compared to other types of metals.

- <p>Aluminum offers several advantages over other metals, including its low density, which makes it lightweight and ideal for applications requiring reduced weight. It also has excellent corrosion resistance, protecting it from rust and other forms of degradation. Aluminum is highly malleable and ductile, allowing it to be easily shaped into various forms. It has high thermal and electrical conductivity, making it suitable for heat exchangers and electrical wiring. Additionally, aluminum is abundant and relatively inexpensive compared to other metals, and it is fully recyclable with minimal loss in quality, contributing to its sustainability.</p>

- Q: Is it possible to join aluminum pieces together using welding techniques?

- <p>Yes, aluminum can be welded. Welding aluminum is a common practice in various industries due to its lightweight and corrosion-resistant properties. Techniques such as Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), and Shielded Metal Arc Welding (SMAW) are used. However, aluminum welding requires specific precautions, such as using a clean, dry surface and a proper shielding gas to prevent oxidation, as aluminum readily reacts with oxygen.</p>

- Q: This question asks for the typical origins of aluminum in the environment.

- <p>Aluminum is the most abundant metal in the Earth's crust, and it is widely present in the environment. Common sources include: 1) Natural weathering of rocks and soil, which releases aluminum into the environment. 2) Industrial processes such as aluminum production, which can release aluminum into the air and water. 3) Food and water, where aluminum can be found naturally or as a result of contamination. 4) Household products like aluminum foil, cans, and cookware, which can contribute to aluminum exposure. 5) Medications and vaccines, which sometimes contain aluminum as an adjuvant. 6) Cosmetics and personal care products, which may contain aluminum compounds. These sources contribute to the overall aluminum exposure in the environment and to humans.</p>

- Q: This question asks for recent applications of aluminum in the transportation industry.

- <p>Aluminum has found new uses in transportation due to its lightweight and high strength properties. It's increasingly used in electric vehicles to reduce weight and extend battery life. Aluminum alloys are also utilized in the construction of high-speed trains and aircraft to improve fuel efficiency and performance. In addition, aluminum is employed in the manufacturing of automotive parts such as engine components, wheels, and body panels. Furthermore, it's used in the production of lightweight bicycles and other transportation infrastructure like bridges and road signs. The trend towards more sustainable and efficient transportation continues to drive innovative uses for aluminum.</p>

- Q: Explain how the incorporation of titanium into aluminum alloys influences their properties and strength.

- <p>Adding titanium to aluminum alloys significantly enhances their mechanical properties and strength. Titanium increases the alloy's strength, hardness, and resistance to corrosion. It also improves the alloy's creep resistance, which is crucial for high-temperature applications. The addition of titanium refines the grain structure, leading to better ductility and toughness. Moreover, titanium helps to reduce the likelihood of stress-corrosion cracking, making the alloy more reliable in aggressive environments. Overall, titanium-aluminum alloys are stronger, more durable, and have a wider range of applications than pure aluminum or simple aluminum alloys.</p>

- Q: This question asks about the safe usage of aluminum in everyday life.

- <p>Aluminum is widely used in daily life due to its lightweight and corrosion-resistant properties. To use aluminum safely, ensure that aluminum cookware is not used for acidic foods as it may leach aluminum into the food. Avoid storing acidic beverages like soda in aluminum cans for extended periods. Use aluminum foil in moderation, especially when cooking at high temperatures, as it can release aluminum into food. Always wash aluminum utensils thoroughly before and after use. For aluminum cans, recycle them to reduce environmental impact and avoid ingestion of aluminum particles from damaged cans.</p>

- Q: Explain the interaction between aluminum and water, including any chemical reactions or properties.

- <p>Aluminum and water do not react directly under normal conditions. Aluminum is a reactive metal, but it is protected by a thin layer of aluminum oxide that forms on its surface when exposed to air, which prevents further reaction with water. This oxide layer is stable and acts as a barrier, making aluminum resistant to corrosion. However, in certain conditions, such as when aluminum is in contact with water and an electrolyte, it can lead to a process known as electrochemical corrosion. Additionally, aluminum can react with steam at high temperatures to form aluminum oxide and hydrogen gas.</p>

- Q: This question asks for innovative applications of recycled aluminum in various industries or everyday life.

- <p>Recycled aluminum is finding new uses in various sectors due to its sustainability and strength. It's being used in the automotive industry to make lighter vehicles, reducing fuel consumption and emissions. In construction, it's used for building materials like window frames and roofing, known for durability and energy efficiency. Recycled aluminum is also employed in the aerospace industry for aircraft parts due to its lightweight and high strength-to-weight ratio. Additionally, it's used in packaging, reducing waste and conserving resources. In electronics, recycled aluminum is used in the manufacturing of various components, contributing to the circular economy.</p>

- Q: This question asks about the general environmental impact of using aluminum.

- <p>The use of aluminum has both positive and negative environmental impacts. On the positive side, aluminum is lightweight and durable, which can reduce the energy needed for transportation. It is also recyclable, and recycling aluminum saves up to 95% of the energy required to produce new aluminum from raw materials. However, on the negative side, the production of aluminum is energy-intensive and generates significant greenhouse gas emissions. The process also produces toxic byproducts, such as fluorides, which can contaminate water and soil. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. Overall, while aluminum has its benefits, its production and use have substantial environmental consequences that need to be managed responsibly.</p>

Send your message to us

Aluminum Mill Finished Circle for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords