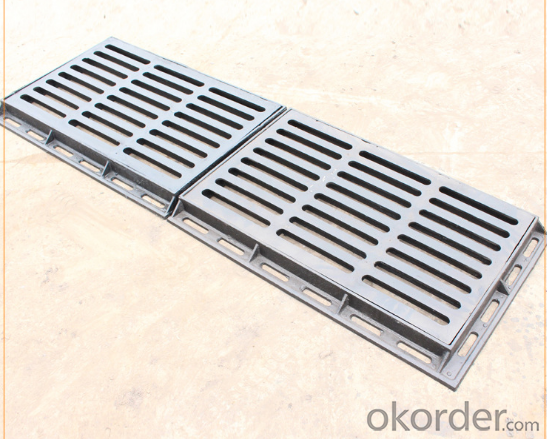

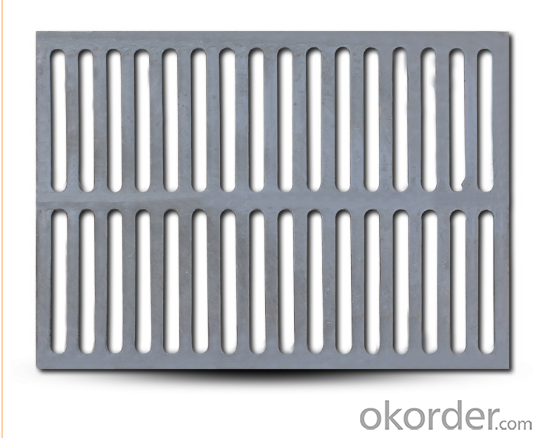

Cast EN 124 ductile iron manhole cover with high quality for industry in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

4) Sand casting

5).we can produce as per customers'drawings

6)ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| TD1221 | D400 | 1220*675 | 1378*831 | 100 | 216 |

| TD1222 | D400 | 1220*675 | 1370*830 | 150 | 80.5 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3.Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

4.Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- 1, gray cast iron: General graphite annealing, to be heat treatment annealing, surface hardening etc.; ductile iron can be various: annealing, normalizing, quenching and isothermal quenching, surface treatment, chemical heat treatment.2. Pouring liquid metal into the casting cavity which adapts to the shape of parts. After cooling and solidification, the casting method is called casting. Castings obtained by casting are called castings. Casting structure design: ensure the working performance and mechanical performance requirements, consider the technical requirements and performance of alloy casting casting casting structure, casting structure design is reasonable or not, the casting quality, productivity and cost has a great influence.3. Heat treatment is a metal hot working process in which the material is in solid state by means of heating, heat preservation and cooling to obtain desired microstructure and properties

- Q: Why do cheap cars like stamping parts instead of casting parts?

- We usually say that the stamping is usually refers to the cold stamping parts, for example, a piece of iron, wants to turn it into a fast food dish, it must design a set of mold, mold is working face plate shape, the pressure plate mold, it becomes you want the dishes, this is the cold stamping die stamping is the direct use of metal materials.Automobile stamping parts are mainly classified according to process, and can be divided into two major parts: separation process and forming process.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What is the difference between forging parts and casting parts?

- Forging is in hot state through the metal hammer or press equipment produced by forging parts. A casting is a metal that is liquid and is poured into a cavity of a specified shape and cooled and solidified. It is the forging metal soft pinch molding, and casting the metal into thin cooling solidification.Forged parts are costly and have long production cycles.

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- Corundum sand: the main mineral composition is corundum alpha -Al2O3, used for investment casting, ceramic mold casting shell materials. The olivine sand: the main mineral composition of olivine (MgFe) 2SiO4, used in cast iron, non-ferrous alloy castings and high manganese steel casting molding sand and the core sand. Silica resources in nature resources, but suitable for casting with high SiO2 content of natural silica sand is not too much. Since 1951, China has carried out a general survey of the casting sand resources in the territory, but mainly limited to the main traffic lines and major industrial cities. Survey results show that Chinese can be used for natural silica sand casting is very rich in resources, a wide range of distribution. Inner Mongolia Zhelimumeng, natural silica sand reserves amounted to hundreds of millions of tons, the particle shape close to the circular, the content of SiO2 is about 90%. Fujian, Jinjiang Dongshan sea sand, the content of SiO2 is 94 to 98%, with a low volume of mud, are good natural silica sand. Are Duchang, Yongxiu Jiangxi County Xingzi, a large number of Quaternary lacustrine deposition of silica sand, the content of SiO2 is about 90%, low iron content, alkaline oxide less, uniform size, is a good lake sand. Guangzhou, Hunan and other places have abundant easily broken weathered sandstone, processing artificial silica sand, the content of SiO2 in more than 96%, can be used for the production of steel castings. Jiangsu Nanjing red sand, sandy mud pure, moderate, strong permeability, good viscosity, high silica content, less water, fine particles, pulls out the casting is smooth, stable quality, can be made of cast iron and non-ferrous metal parts of the sand and core sand

- Q: How much is the amount of electrophoretic paint per square meter used in the casting?

- It was a very simple question, and it was complicated by what you said.In general, when the final thickness of 15-20 microns, cathode electrophoresis paint can be coated per kilogram of 6-8 square meters, the current general cathode electrophoresis paint for the price of 22 yuan / kg, so the cathodic electrophoresis electrophoresis paint cost at 4 yuan / square meters.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- There is a hot knot in the thick area, which easily causes microscopic shrinkage and makes the casting not dense. A riser may be added for shrinkage relief.

- Q: How can the casting be quenched and tempered?

- Cast steel annealing or normalizing parts in strength and toughness is insufficient, can be used in quenching and tempering treatment. It is mainly used for gear, gear and other parts of the cast steel. The conditioning has two kinds: one kind is cast directly after quenching and tempering, with warm water (40---50 degrees) intermittent cooling, suitable for ZG270---500, ZG310----570 and other castings.

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- This is too muchYou do not have a specific list of statistics, but there are many foundries in china!Moreover, car prices are unlikely to be ordered in the local factories!

- Q: What are the general technical requirements for casting parts?

- What kind of casting do you want to know? Copper parts, iron pieces, aluminum pieces??? Their casting conditions are different.

Send your message to us

Cast EN 124 ductile iron manhole cover with high quality for industry in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches