Cast Ductile Iron Manhole Covers D400 C250 for Mining with Competitive Prices Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

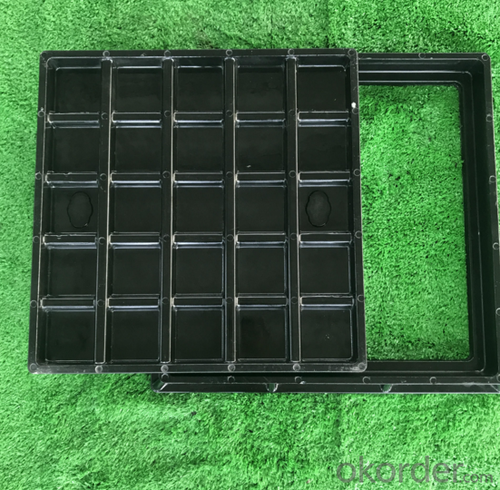

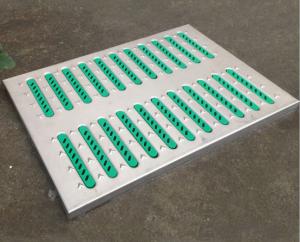

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type: round type and Square type, triangle

4) Sand casting

5) we can produce as per customers' drawings

6) ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| PBC700 | B125 | 600×600 | 700×700 | 40 | 37 |

| PBC800 | B125 | 700×700 | 800×800 | 40 | 47 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3.Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

4.Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

- Q: How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q: Why do cheap cars like stamping parts instead of casting parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute. The purpose of forming processes is to allow the sheet to undergo plastic deformation without breaking the billet and to make the desired shape and size. In actual production, a variety of processes are often applied to a workpiece. Blanking, bending, shearing, drawing, bulging, spinning, and straightening are the main types of stamping machines.

- Q: The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q: Cause of choking of casting parts

- The reason is not in the coated sand, see coating gas evolution, the best use of zircon powder coating (low gas evolution), there is a mold according to a vent needle, this depends on your way is flat or vertical pouring pouring pouring, if vertical pouring, venting pin on the die, and the big piece how could the plane, pouring water flat, a breath, a taboo ah!

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- What kind of work, what kind of material, 204201304316, how big live ah? You ask?Can the 201 pieces of material and 304 of the pieces fit in a single car? Can I use the universal YG8 knife? Straight, knife, pipe thread?You should live to say, understand, say, do not understand, draw a simple drawing with Baidu doodle, marking the important size, this is good to answer ah!

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- (3) to prevent generating white grey cast iron, in addition to taking measures from the process, must make the wall thickness is not too thin (some sources indicate that the corner wall thickness above 15mm, metal type casting must be in the corner, for Aluminum Alloy, magnesium alloy casting casting casting Create fillet should not be less than 3-4m, for casting round cast iron, copper alloy mould casting can see table 1.1-32 selection; (5) because of the metal and the core without let, for the convenience of the casting is taken out and the draw out type, slope casting casting should be suitably large than sand casting metal casting. General 30%-50%, it should be pointed out that in addition to the height of the slope of casting size and alloy type, wall, is also related to the casting surface position, where the cooling and contraction and metal surface of casting surface can be designed from the tendency of small inclination, while casting shrinkage tend to be pressed on the surface of metal castings the type should be given greater inclination, all kinds of metal type alloy casting casting casting.

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting. It is comprehensive. There is no simple comparison of the material to determine the degree of difficulty in processing

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

- Q: What's the cause of the choking of the casting?,

- 2. when casting mold exhaust condition is not good, in the casting material use consider whether and hinder its gas permeability; in the process to consider to release more pores, multi venting; core exhaust is particularly important.

Send your message to us

Cast Ductile Iron Manhole Covers D400 C250 for Mining with Competitive Prices Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords