Cast Ductile Iron Manhole Covers D400 C250 for Industries with Competitive Price in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

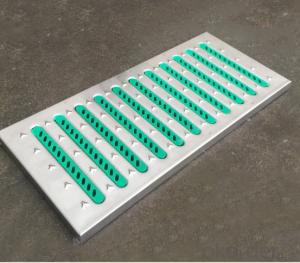

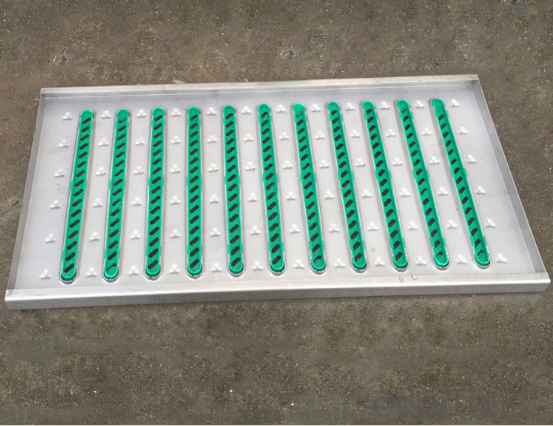

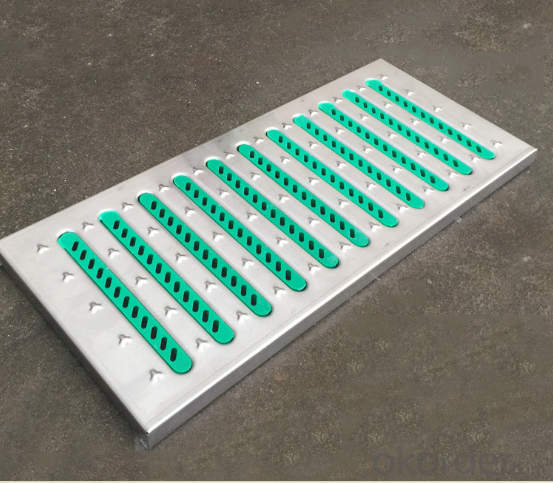

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

4) Sand casting

5).we can produce as per customers'drawings

6)ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| SC42 | C250 | 330*330 | 420*420 | 50 | 20 |

| RGC-01L | C250 | 390*325 | 530*465 | 100 | 23 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. Can I get free samples?

A: Yes, we can provide the free samples, but you need to bear delivery freight.

3. Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your requirement, but it maybe let your purchasing cost changed also.

- Q: What's the effect of casting copper?

- Copper is one of the main corrosion resistant alloys. When the mass fraction of copper in cast iron is from 0.25% to 1%, the corrosion resistance of copper in the industrial atmosphere can be obviously increased. But copper has very little corrosion resistance in lye or salt solution.Copper can increase the flowability of molten iron and improve its casting ability remarkably.Copper can increase the coercive force and residual magnetic force, but the permeability is not affected.Combined use of copper with other alloy elements, such as copper chromium, copper chromium molybdenum, copper molybdenum, copper manganese, copper vanadium, can achieve greater results.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- You oily sludge!Is not the general market on the soil?If it isPlease use two groups of chemicals to reinforce the soilOr suggest your company?Do the putty or paint film after doingThat's better

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: It is generally said that cast iron is re smelted by pig iron. My question is..:1 pig iron for melting iron, is directly cast into products (such as bed cover, etc.); or that is just the first pig iron smelting iron casting, such as to cover, bed and other products, will once again cast iron melt to casting?2, there are many castings to the engine. Are these castings made by the engine manufacturer themselves or bought by others?There is no need to answer all. Thank you!!!

- 1, qualified enterprises will directly iron ore into molten iron, and then poured into the mold, such a good product performance. I work in the cast iron industry, which I can tell you for sure.2, this, like the Great Wall Motor Company has its own parts production department, as well as the corresponding mold center, so it will be their own casting. If the manufacturer does not have these departments, they can only place orders for others to do.

- Q: In theory, which is more expensive, forging parts or casting parts?

- The structure of the casting is relatively flexible in design, and the modeling is easy to realize.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- Radial drilling machine can achieve boring, reaming function, but as much as you want, according to your requirements and material to determine!

- Q: How to cast iron and wrought iron collocation

- So we can only watch and ear distinction: 1, see: Iron fracture is rough, showing a bead (for the sake of coarse grain iron), and wrought iron fracture is generally more smooth; if this is a new fracture, but also to see the dark and shiny born iron wrought iron pig iron is bright; the fracture is generally irregular, because it is very brittle, mostly is interrupted, (which is processed, it is very flat and wrought iron) must not be interrupted, mostly by certain way processed separately, so the fracture is generally neat; if the fracture is that is cutting, wrought iron, iron is not cutting; iron surface will not have pores, familiar iron porosity; if a piece of iron is a significant deformation (bending) that is wrought iron because of poor plasticity It doesn't have to be so deformed, it's really bent, or it's broken, or it's obviously cracked, and it doesn't bend very much. There are some details that can not be made clear. It is necessary to have some experience.

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguishing between forging and casting can be done from the following points:From the principle of distinguishingForging processing of machining by hammer or press and other equipment for forging parts produced in hot state, casting processing of metals into liquid, pouring into the cavity with a specific shape, produced by machining parts after cooling solidification. Simply say that forging is the metal soft pinch molding, and casting the metal into thin cooling solidification.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

Send your message to us

Cast Ductile Iron Manhole Covers D400 C250 for Industries with Competitive Price in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords