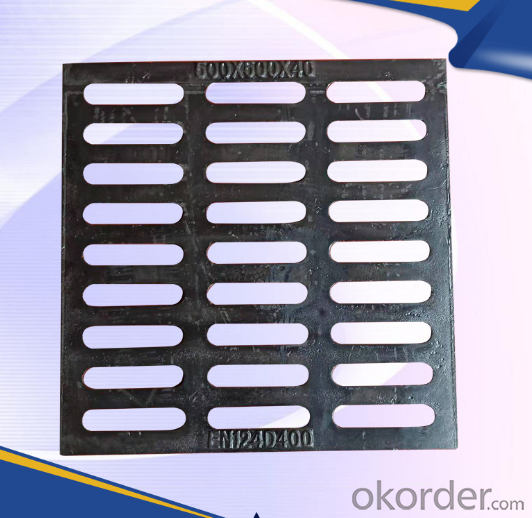

Cast ductile iron manhole cover for mining made in Hebei Province

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) we can produce as per customers'drawings

4) Waterproof and anti-rust

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) |

| CCUC68HK | C250 | 500*700 | 600*800 | 60 |

| CCUC70HK | C250 | 600*600 | 700*700 | 50 |

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

Advantages

Good compressive, bending and impact strength, anti-rust, endurable period (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. Can I get free samples?

A: Yes, we can provide the free samples, but you need to bear delivery freight.

3.How about your service?

A: Free charge of design labels and cartons.

Our products: produced by the hydraulic Press.Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

Professional technical support with free charge.

- Q: Why does the precision casting factory not usually make iron castings?

- Because it is too cheap, the design of materials is cast iron, generally do not have very high requirements.

- Q: What's the effect of casting copper?

- Copper is one of the main corrosion resistant alloys. When the mass fraction of copper in cast iron is from 0.25% to 1%, the corrosion resistance of copper in the industrial atmosphere can be obviously increased. But copper has very little corrosion resistance in lye or salt solution.Copper can increase the flowability of molten iron and improve its casting ability remarkably.Copper can increase the coercive force and residual magnetic force, but the permeability is not affected.Combined use of copper with other alloy elements, such as copper chromium, copper chromium molybdenum, copper molybdenum, copper manganese, copper vanadium, can achieve greater results.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Cast iron has not been done, if it is iron, then in the spray before going through strict pretreatment, the surface can not have a little oil dust

- Q: Is the cast steel a casting part?

- Cast steel is one of the casting parts that you call. The material is made of carbon steel or alloy steel, stainless steel, etc. the method is cast

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- The main content of red sand table (Institute of soil science, China) silica 79.4%. three 1.48%. three 10.55%. two aluminum oxide iron oxide, calcium oxide 0.85%. Magnesium Oxide 0.52%. 1440. refractory mud 3.06% LOI 1.98% red sand with high silicon content, permeability is strong, durable, high refractoriness, good angle, low moisture content, less mud the casting finish is high, the basic requirements of sand should meet the following requirements: Casting of high purity and cleanliness, with silica sand as an example, iron sand SiO2 content of more than 90%, the big steel casting requests the SiO2 content of more than 97%; the high refractoriness and thermal stability; the suitable particle the shape and particle composition; it is not easy to be wetted by the liquid metal; cheap. The particle shape and composition of casting sand particle shape and particle composition permeability properties such as mobility, sand compaction, permeability, strength and resistance to liquid metal effects, is an important indicator of the quality of casting sand.

- Q: How to distinguish the forging parts and casting parts accurately

- Distinguishing between forging and casting can be done from the following points:From the principle of distinguishingForging processing of machining by hammer or press and other equipment for forging parts produced in hot state, casting processing of metals into liquid, pouring into the cavity with a specific shape, produced by machining parts after cooling solidification. Simply say that forging is the metal soft pinch molding, and casting the metal into thin cooling solidification.

- Q: What is the casting material?

- The casting material is usually made of gray cast iron, nodular cast iron and vermicular graphite cast iron

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- Casting parts do not need to provide drawings of casting blank, the casting factory according to your drawings in the required surface will be sufficient allowance, and the rest of the size according to the mechanical design manual and the casting manual can be found.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: What kind of flaw detector is better for casting parts?

- If the casting is very small, can be used for fixed magnetic detection machines, of course with fixed magnetic powder the testing machine, the best first contact the manufacturers, because the fixed magnetic particle testing machine belongs to the non-standard equipment, according to the workpiece size, different shape, manufacturing daily inspection and measurement.

Send your message to us

Cast ductile iron manhole cover for mining made in Hebei Province

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches