Casting ductile iron manhole cover for mining made in Hebei Province

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Overview

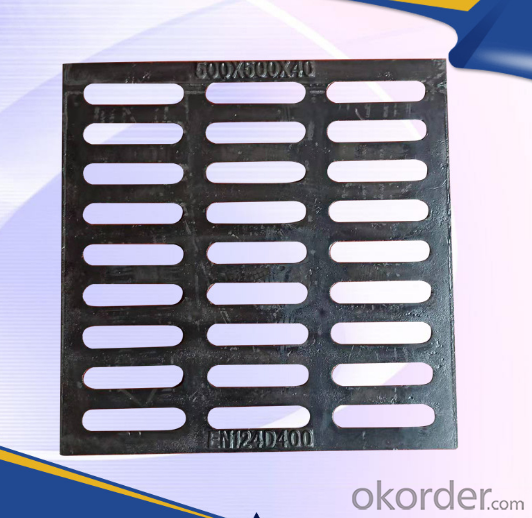

Quick Details

Place of Origin:

Hebei, China (Mainland)

Brand Name:

CMAX

Model Number:

EN124 Standard

Application:

Industry

Material:

Iron

Dimensions:

Customer Required

Standard:

EN124 Standard

Process:

Casting. Deburring .Drilling .threading

Name:

Precision Die Casting Parts

Type:

Moulding Press

Certification:

ISO9001-2008

Color:

Original Color

Surface treatment:

Painting

Service:

OEM ODM

Product name:

OEM Products

Item:

OEM China Die Casting

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) |

| CCUC68HK | C250 | 500*700 | 600*800 | 60 |

| CCUC70HK | C250 | 600*600 | 700*700 | 50 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, endurable period (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film,

Delivery Detail: we will deliver your goods within 30 days after your purchasing of our goods.

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2.How about your time of delivery?

A:Within in 30 days after the order is concluded.

- Q: Domestic large steel castings factory which is better, recommend!

- At least spend money on research and development, then the quality should be all right.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What is the difference between forging parts and casting parts?

- The casting parts are low in cost and short in production period. Because the molten iron has good flow properties, complex shapes can be formed. But because there may be sand holes, pores, shrinkage holes and other defects, the quality is unstable, easy to produce many defects, mechanical properties are not forged well, thus affecting the service life.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- There is a hot knot in the thick area, which easily causes microscopic shrinkage and makes the casting not dense. A riser may be added for shrinkage relief.

- Q: What are the causes of pitting on the surface of a precision casting?

- The quality of the shell surface is out of order. Or shot blasting out of question.

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- Yes, the cast aluminium is polarized and gray, but the key problem is to guarantee the quality of the aluminium casting, and the quality of the other aluminium casting is not good.

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Valve sand core mold drying is not in place, excessive water content

- Q: What are the general technical requirements for casting parts?

- No matter what kind of material casting, there are the following major requirements:Material requirements. Mainly hardness, tensile strength, elongation, impact toughness.Two, dimensional accuracy and shape accuracy. Different castings have different requirements. Different sizes and geometric tolerances and different tolerances are adopted.Three, according to the use requirements, the casting of other defects, acceptance requirements. Such as holes, sand holes, shrinkage, slag, sand, crack.........Four. Requirements for defect repair.

- Q: When the blank is a casting, the margin is evenly distributed, how should rough machining?Please help friends from mechanical classes.There is another problem: in the NC milling plane contour machining, when the rough margin is large, how to deal with.Who can help in time, add 20 reward. Urgently!!

- Personal advice:Because of the large margin, your outline is easy to guarantee;So the key is to consider the assembly and aesthetics of the casting. You have to find the machining criteria;Rough the datum so that it can be machined;After the outline, turn back to the finishing line.If the casting requirement is not high, the benchmark can be directly processed; (not recommended)Over

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- A: in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

Send your message to us

Casting ductile iron manhole cover for mining made in Hebei Province

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches