Carbon Structural Steel Round Bars ST37-2CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Structural Steel Round Bars ST37-2CR

Product Specification

1, Chemical Composition %

| Grade | C | Si | Mn | S | P | Cr |

| ST37-2CR | 0.21-0.25 | ≤0.35 | ≤1.4 | ≤0.045 | ≤0.045 | ≥0.30 |

2, Mechanical Properties

| Strength of Extension σb | Yield Strength σs | Impact AKv |

| 340-470 Mpa | ≥235 Mpa | ≥27J |

3, Diameter: 9mm - 80mm

Application

1, Widely used in construction and engineering structure.

2, Widely used in making reinforcing steel bar or building plant room rack, high voltage transmission tower, bridge, vehicle, boiler, vessel, ship, etc.

3, Widely used in manufacturing mechanical parts which are not required to be with high performance.

Product Main Points

1, Heat Treatment: normalizing, annealing, tempering, quenching

2, Surface Treatment: black, grinding, bright, polish

3, Product Process: hot rolled, cold drawn, forged

FAQ

1, Payment Terms:

30% T/T deposit & 70% T/T before delivery.

Irrevocable L/C at sight

2, Trade Terms:

EXW, FOB, CIF, CNF

3, Delivery Time:

Normally 30-40 days. According to quantity.

4, Manufacture or Trading Company:

CNBM is a state-owned fortune global 500 trading company. We have intergrated supply system.

There are about 20 overseas locations in different countries.

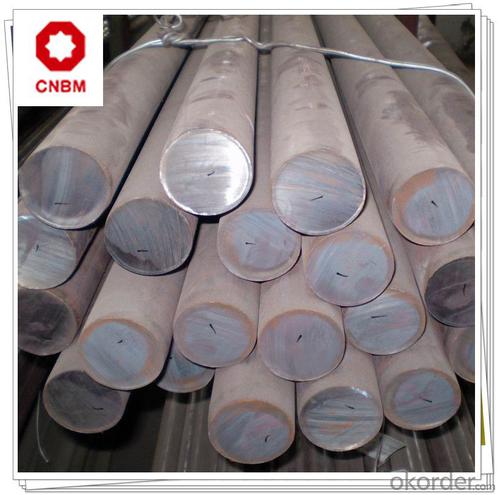

Product Show

Work Shop

About Us

- Q: What is the hardness of a steel round bar?

- The hardness of a steel round bar can vary depending on the specific type of steel used and the manufacturing process, but it is typically measured on the Rockwell or Brinell hardness scales.

- Q: What is the maximum weight that can be lifted using a steel round bar as a lifting rod?

- The lifting capacity of a steel round bar depends on several factors, including its diameter, length, material composition, and lifting technique. Different steel round bars have different load-bearing capacities based on their dimensions and grade. Engineering principles and specific formulas can be used to calculate the load-bearing capacity of a steel bar based on its material and geometry. To determine the maximum weight that can be lifted with a particular steel round bar, it is important to consider its ultimate tensile strength, yield strength, and factor of safety. The ultimate tensile strength represents the maximum stress the material can handle before failure, while the yield strength is the stress at which permanent deformation occurs. The factor of safety is a design parameter that takes uncertainties into account and ensures structural integrity. To obtain accurate and reliable information about the load-bearing capacity of a specific steel round bar, it is crucial to consult engineering references, standards, or professionals. They can provide the necessary calculations, considering the bar's diameter, length, material properties, intended lifting application, and safety requirements. In conclusion, the maximum weight that can be lifted using a steel round bar as a lifting rod depends on various factors and cannot be determined without considering the specific characteristics of the bar and the lifting scenario. Consulting engineering resources or experts is essential to ensure safe and accurate calculations.

- Q: What is the standard length of a steel round bar?

- The standard length of a steel round bar can differ based on the specific industry and its intended usage. Nevertheless, in most cases, a steel round bar typically measures 20 feet or 6 meters. This particular length finds extensive application in construction, manufacturing, and engineering sectors. It is worth mentioning that custom lengths can also be acquired to align with the specific needs of a project or application.

- Q: What are the different heat treatment methods for steel round bars?

- Some of the common heat treatment methods for steel round bars include annealing, normalizing, quenching, tempering, and case hardening.

- Q: Can steel round bars be coated or painted?

- Yes, steel round bars can be coated or painted. Coating or painting steel round bars serves several purposes, such as preventing corrosion, enhancing aesthetics, and providing additional protection against environmental factors. Coatings and paints can be applied to steel round bars using various methods, including powder coating, electroplating, or wet paint application. These processes involve preparing the surface of the steel round bar by removing any existing rust or contaminants, followed by the application of the chosen coating or paint. The type of coating or paint used will depend on the specific requirements of the steel round bars, such as the intended use, environmental conditions, and desired appearance. Coating or painting steel round bars can significantly extend their lifespan, improve their visual appeal, and ensure their durability in various applications.

- Q: Can steel round bars be used for making tie rods?

- Indeed, tie rods can be fashioned from steel round bars. Owing to their robustness and endurance, steel round bars find widespread usage in the realm of construction and engineering. By offering structural reinforcement and stability, tie rods serve a vital purpose, and steel round bars are particularly appropriate for this task. Possessing remarkable tensile strength, they can withstand substantial loads and tension, rendering them a perfect selection for tie rods. Moreover, steel round bars enable effortless fabrication and welding, thereby allowing for adaptability and versatility in the creation and assembly of tie rods.

- Q: What are the advantages of using high-strength steel round bars?

- There are several advantages to using high-strength steel round bars in various applications. Firstly, high-strength steel round bars are known for their exceptional strength-to-weight ratio. This means that even though these bars are lighter in weight compared to other materials, they possess a significantly higher strength. This advantage allows for the construction of structures that are both sturdy and lightweight, making them ideal for applications where weight reduction is crucial, such as in the aerospace and automotive industries. Secondly, high-strength steel round bars offer excellent resistance to wear, fatigue, and impact. This characteristic makes them highly durable and able to withstand heavy loads and repeated stress, enhancing the overall lifespan and performance of structures or components made from these bars. This advantage is particularly beneficial in applications such as construction, where the materials are subjected to extreme conditions and must maintain their structural integrity over time. Furthermore, high-strength steel round bars provide improved design flexibility due to their versatility. They can be easily shaped, machined, and welded, allowing for the creation of complex and customized structures or components. This advantage enables engineers and designers to optimize their designs and achieve specific performance requirements, resulting in more efficient and innovative solutions. In addition, high-strength steel round bars offer enhanced resistance to corrosion, making them suitable for applications where exposure to harsh environmental conditions or corrosive substances is a concern. By utilizing high-strength steel round bars, structures or components can maintain their integrity and functionality for extended periods, reducing the need for frequent maintenance and replacement. Finally, using high-strength steel round bars can lead to cost savings in the long run. Although the initial cost of these bars might be higher compared to other materials, their superior strength and durability can significantly reduce maintenance, repair, and replacement costs over time. Additionally, the lightweight nature of high-strength steel round bars can contribute to fuel efficiency, resulting in cost savings in transportation and other industries. Overall, the advantages of using high-strength steel round bars include high strength-to-weight ratio, excellent resistance to wear and fatigue, improved design flexibility, enhanced corrosion resistance, and potential cost savings. These benefits make high-strength steel round bars a preferred choice for a wide range of applications, ranging from construction and manufacturing to transportation and infrastructure.

- Q: Can steel round bars be painted or coated?

- Yes, steel round bars can be painted or coated with various types of protective coatings to enhance their durability and prevent corrosion.

- Q: What are the different grades of stainless steel round bars for marine applications?

- For marine applications, stainless steel round bars come in various grades. The commonly used grades are 304, 316, and 316L stainless steel. Grade 304 stainless steel is a versatile alloy known for its good corrosion resistance, high strength, and excellent formability. It is often utilized in marine applications that require moderate corrosion resistance. Grade 316 stainless steel is similar to grade 304 but contains additional molybdenum. This enhances its corrosion resistance, especially against chlorides and other aggressive marine environments. Grade 316 is preferred in marine settings that demand increased resistance to corrosion. Grade 316L stainless steel is a low carbon version of grade 316. Its resistance to sensitization and intergranular corrosion is further improved. This makes it highly suitable for marine applications that involve welding, reducing the risk of corrosion at the welds. Apart from these grades, there are specialized stainless steel alloys like duplex stainless steel. These alloys combine the advantages of austenitic and ferritic stainless steels, offering even greater corrosion resistance and strength. They are suitable for demanding marine applications. When choosing stainless steel round bars for marine applications, it is crucial to consider specific environmental conditions such as exposure to saltwater, chemicals, or high temperatures. Seeking guidance from a materials specialist or referring to industry standards can help ensure the appropriate grade is selected for the specific marine application.

- Q: What are the different types of steel round bars used in the power generation industry?

- In the power generation industry, various types of steel round bars are utilized for different applications. These round bars are specifically chosen for their unique properties and characteristics that are required in various power generation processes. Some of the different types of steel round bars commonly used in the power generation industry include: 1. Carbon Steel Round Bars: Carbon steel round bars are widely used due to their affordability, strength, and ease of fabrication. They are commonly used in power generation equipment such as turbines, generators, and boilers. 2. Alloy Steel Round Bars: Alloy steel round bars are made by combining carbon steel with other elements such as chromium, nickel, and molybdenum to enhance their mechanical properties. These bars offer increased strength, corrosion resistance, and heat resistance, making them suitable for high-pressure and high-temperature applications in power plants. 3. Stainless Steel Round Bars: Stainless steel round bars are highly corrosion-resistant and exhibit excellent heat resistance. They are commonly used in power generation equipment that comes into contact with water or steam, such as condensers, heat exchangers, and valves. 4. Tool Steel Round Bars: Tool steel round bars are known for their exceptional hardness, wear resistance, and toughness. They are commonly used in power generation equipment that undergoes frequent machining, cutting, or forming processes, such as drilling equipment and turbine blades. 5. High-Speed Steel Round Bars: High-speed steel round bars are specifically designed to withstand high temperatures and maintain their hardness and cutting ability at elevated speeds. They are commonly used in power generation equipment, such as cutting tools, drills, and milling machines. 6. Duplex Steel Round Bars: Duplex steel round bars are a combination of austenitic and ferritic stainless steels, offering excellent strength, corrosion resistance, and weldability. They are commonly used in power plants for applications such as piping systems, pressure vessels, and heat exchangers. It is worth noting that the specific steel round bars used in the power generation industry can vary depending on the requirements and operating conditions of each power plant. Therefore, it is essential to consult with engineers and experts to determine the most suitable type of steel round bars for a particular power generation application.

Send your message to us

Carbon Structural Steel Round Bars ST37-2CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords