Carbon Structural Steel Square Bars SAE1018CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Structural Steel Square Bars SAE1018CR

Product Specifiction

1, Chemical Composition %

| Grade | C | Si | Mn | S | P | Cr | Ni | Cu |

| SAE1020CR | 0.15-0.20 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 |

2, Mechanical Properties

| Strength of Extension σb | Yield Strength σs | Elogation δ5 | Reduction of Area ψ | Hardness |

| ≥410(42) Mpa | ≥245(25) Mpa | ≥25 % | ≥55 % | ≤156HB |

Application

Carbon steel applies to chemical industry, shipping industry,manufacturing industry, construction, decorate industry, electric power, pump shafts, sanitary wares, furniture handles, boiler, high temperature resistant, low temperature resistant, corrosion resistant.

Product Main Points

1, Heat Treatment: normalizing, annealing, tempering, quenching

2, Surface Treatment: black, grinding, bright, polish

3, Product Process: hot rolled, cold drawn, forged

FAQ

1, Payment Terms:

30% T/T deposit & 70% T/T before delivery.

Irrevocable L/C at sight

2, Trade Terms:

EXW, FOB, CIF, CNF

3, Delivery Time:

Normally 30-40 days. According to quantity.

4, Manufacture or Trading Company:

CNBM is a state-owned fortune global 500 trading company. We have intergrated supply system.

There are about 20 overseas locations in different countries.

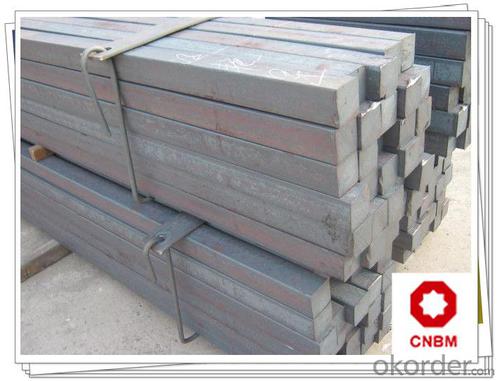

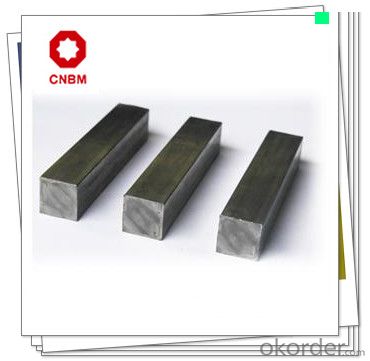

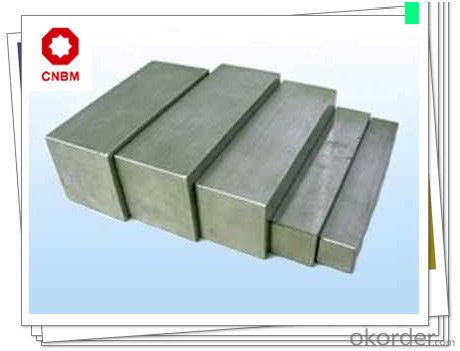

Product Show

Work Shop

About Us

- Q: What are the advantages of using vanadium-alloy steel round bars?

- There are several advantages of using vanadium-alloy steel round bars. Firstly, vanadium increases the strength and toughness of the steel, making it highly durable and resistant to wear and tear. This makes it ideal for applications that require high strength and reliability, such as construction, automotive, and machinery industries. Secondly, vanadium-alloy steel has excellent heat resistance, allowing it to withstand high temperatures without losing its mechanical properties. This makes it suitable for use in environments with elevated temperatures or in applications involving heat treatment processes. Lastly, vanadium-alloy steel offers improved corrosion resistance, reducing the risk of rust and corrosion, and increasing the lifespan of the round bars. Overall, the use of vanadium-alloy steel round bars provides enhanced performance, durability, and reliability, making them a preferred choice in various industrial applications.

- Q: What are the cost considerations for steel round bars?

- The cost of steel round bars can vary depending on several factors. Firstly, the cost can be greatly influenced by the type and grade of steel used in production. Different types of steel, such as carbon steel, alloy steel, or stainless steel, have varying costs due to differences in their composition and properties. Higher grade steel, which offers superior strength and durability, tends to be more expensive compared to lower grade options. Secondly, the cost is affected by the size and dimensions of the round bars. Larger diameter and length of the bars require more raw material and additional processing, resulting in higher costs. Moreover, specialized shapes or custom sizes may necessitate extra manufacturing steps or tooling, which can increase the overall price. The quantity or volume of round bars ordered can also impact the cost. Bulk orders typically benefit from economies of scale, leading to reduced unit costs. Additionally, longer-term contracts or partnerships with suppliers can result in better pricing agreements. It is important to consider transportation and logistics expenses as well. The cost of shipping steel round bars can vary based on factors such as distance, mode of transportation, and handling requirements. International shipping, for example, may involve additional customs duties and taxes. Lastly, market conditions and fluctuations in the steel industry can have an impact on the cost of round bars. Factors like supply and demand, raw material costs, and currency exchange rates can all influence the final price. It is crucial to stay updated with market trends and work closely with suppliers to negotiate favorable pricing. To ensure that the cost of steel round bars aligns with your budget and meets your specific requirements, it is essential to conduct thorough research, compare quotes from multiple suppliers, and evaluate the quality-to-price ratio before making a decision.

- Q: Are steel round bars resistant to chemicals or acids?

- Yes, steel round bars are generally resistant to chemicals and acids due to their high corrosion resistance properties. However, the level of resistance may vary depending on the specific type of steel and the concentration and temperature of the chemicals or acids involved.

- Q: Can steel round bars be used for making turbine blades?

- No, steel round bars are typically not used for making turbine blades. Turbine blades are often made from materials such as titanium or nickel-based superalloys, which provide the necessary strength, heat resistance, and aerodynamic properties required for efficient turbine operation.

- Q: What are the safety precautions when handling steel round bars?

- When handling steel round bars, there are several important safety precautions that should be followed to minimize the risk of accidents or injuries. 1. Personal Protective Equipment (PPE): Always wear appropriate PPE such as safety goggles, gloves, steel-toed boots, and a hard hat. These protective gears help protect against potential hazards such as flying debris, sharp edges, and heavy objects. 2. Proper Lifting and Carrying Techniques: Steel round bars can be heavy and cumbersome, so it is important to use proper lifting techniques to avoid strain or injury. Lift with your legs, keeping your back straight, and avoid twisting or jerking motions. If the bars are too heavy to lift alone, ask for assistance or use mechanical aids like forklifts or cranes. 3. Secure Storage and Stacking: When storing or stacking steel round bars, ensure they are properly secured and organized. Use appropriate storage racks or A-frames to prevent them from tipping over or falling, which could cause serious injuries. If stacking multiple bars, use spacers or shims to maintain stability. 4. Avoid Sharp Edges: Steel round bars may have sharp edges or burrs, so be cautious when handling them. Wear gloves to protect your hands and avoid dragging or sliding the bars, as this can cause cuts or abrasions. 5. Proper Handling Techniques: When moving steel round bars, always maintain a firm grip and be aware of your surroundings. Do not swing or throw the bars, as they could hit someone or cause damage. Instead, walk slowly and steadily, ensuring clear paths and ample space to maneuver. 6. Inspection for Defects: Before using steel round bars, inspect them for any defects or damage. Look for cracks, dents, or deformities that could compromise their structural integrity. If any issues are found, do not use the bars and report them to a supervisor or quality control personnel. 7. Fire Safety: Steel round bars are highly flammable when exposed to extreme heat or sparks. Therefore, avoid working near open flames or hot work areas. Keep fire extinguishers nearby and ensure everyone is trained in fire safety protocols. By following these safety precautions, you can significantly reduce the risks associated with handling steel round bars and create a safer work environment.

- Q: Specifications of the same kind of galvanized round bar more expensive than round steel?

- The general market price than ordinary steel galvanized steel bar of your 2000-3000 dollars per ton, according to your purchase requirements, price range of relatively large fluctuations, such as whether to open a formal invoice, transport distance, purchase quantity, relationship with your level of economic development, the developed area of fierce market competition, the price is relatively low. The prices and prices of large factories and small factories are not the same. The prices of big factories are generally high, and the prices of small factories are low.

- Q: Three - grade thread Phi 10 steel can replace a grade Phi 12 round bar? Which elder knows, trouble pointing.

- According to the substitution of steel bars, one method, equal strength substitution, equal area substitution and equal root substitution can be obtained by substitution. Three grades of thread Phi 10, steel replaced by a grade Phi 12 of the round steel, I think it may appear: does not meet the minimum reinforcement ratio requirements and reinforcement construction regulations. Don't change it for the best. But must change, must pass the design.

- Q: How are steel round bars tested for tensile strength?

- Steel round bars are tested for tensile strength using a method called a tensile test. This test measures the resistance of a material to a stretching force, and it is commonly used to determine the mechanical properties of metals. To perform a tensile test on a steel round bar, a sample is taken from the bar in the form of a cylinder or a rectangular shape. The sample is then prepared by removing any surface imperfections or irregularities. Next, the sample is inserted into a testing machine called a tensile testing machine. The machine consists of two grips, one at each end, which securely hold the sample. One grip is fixed while the other is movable. The testing machine applies an increasing force to the sample, causing it to stretch until it eventually breaks. As the force is applied, the machine measures the amount of force required to stretch the sample and records the elongation or deformation of the sample throughout the test. The test results are used to calculate various mechanical properties of the steel round bar, including its ultimate tensile strength. This is the maximum amount of stress the material can withstand before it breaks. Other properties such as yield strength, elastic modulus, and elongation at break can also be determined from the test. Tensile testing is a critical method for determining the quality and suitability of steel round bars for various applications. It helps ensure that the material meets the required specifications and can withstand the expected loads and stresses in its intended use.

- Q: What is the difference between a centerless ground and a hot rolled steel round bar?

- The main difference between a centerless ground steel round bar and a hot rolled steel round bar is the manufacturing process. Centerless grinding involves removing material from the bar's outer diameter using abrasive wheels, resulting in a precise and smooth finish. On the other hand, hot rolling involves heating the steel and passing it through a series of rollers to shape it into a round bar, often resulting in a rougher surface. Additionally, centerless ground bars tend to have tighter dimensional tolerances and better surface quality compared to hot rolled bars.

- Q: What are the different testing methods used for steel round bars?

- Steel round bars undergo various testing methods to guarantee their quality and suitability for different applications. These methods encompass: 1. Visual Inspection: In this preliminary step, the bars are visually assessed for any discernible defects, such as cracks, surface irregularities, or incorrect dimensions. 2. Dimensional checks: To verify their diameter, length, and straightness, steel round bars are subject to dimensional scrutiny. Accurate measurements are imperative to meet specified requirements. 3. Ultrasonic Testing: Internal defects like cracks, voids, or inclusions are detected by passing ultrasonic waves through the round bars. This method identifies potential weaknesses that could compromise the bars' structural integrity. 4. Magnetic Particle Inspection: By utilizing a magnetic field and magnetic particles, this method identifies surface and near-surface defects like cracks, seams, or laps. It is especially advantageous for ferromagnetic materials like steel. 5. Dye Penetrant Inspection: This technique involves applying a colored dye to the round bars' surface and subsequently wiping it off. The dye seeps into any surface cracks or defects, making them visible under ultraviolet light. 6. Hardness Testing: To gauge the hardness of steel round bars, hardness testing is conducted using methods like Rockwell or Brinell scales. It assists in determining the material's ability to withstand external forces and ensures compliance with required hardness specifications. 7. Tensile Testing: This test measures the maximum load a steel round bar can bear before fracturing, providing insight into the material's strength and ductility. 8. Chemical Analysis: Chemical analysis is performed to ascertain the composition of the steel round bars, including the presence of elements like carbon, manganese, sulfur, phosphorus, and others. It guarantees adherence to the required chemical composition standards. These testing methods are vital in ensuring that steel round bars meet industry standards and customer requirements in terms of quality, reliability, and compliance. Employing a combination of these tests is essential to ensure overall quality and performance in various applications.

Send your message to us

Carbon Structural Steel Square Bars SAE1018CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords