Carbon Structural Steel Round Bars SAE1018CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Structural Steel Round Bars SAE1018CR

PRODUCT USE

Carbon steel applies to chemical industry, shipping industry,manufacturing industry, construction, decorate industry, electric power, pump shafts, sanitary wares, furniture handles, boiler, high temperature resistant, low temperature resistant, corrosion resistant.

PRODUCT MAIN POINTS

1, Heat Treatment: normalizing, annealing, tempering, quenching

2, Surface Treatment: black, grinding, bright, polish

3, Product Process: hot rolled, cold drawn, forged

FAQ

1, Payment Terms:

30% T/T deposit & 70% T/T before delivery.

Irrevocable L/C at sight

2, Trade Terms:

FOB, CIF, CNF

3, Delivery Time:

Normally 30-40 days. According to quantity.

4, Manufacture or Trading Company:

CNBM is a state-owned fortune global 500 trading company. We have intergrated supply system.

There are about 20 overseas locations in different countries.

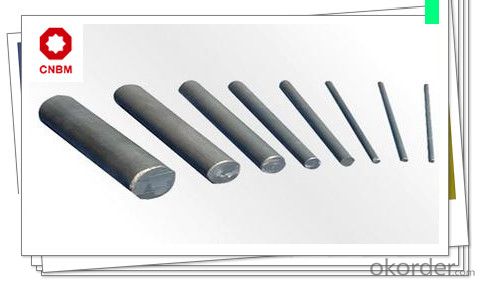

PRODUCT SHOW

PRODUCT SPECIFICATION

1, Chemical Composition %

| Grade | C | Si | Mn | S | P | Cr | Ni | Cu |

| SAE1020CR | 0.15-0.20 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 |

2, Mechanical Properties

| Strength of Extension σb | Yield Strength σs | Elogation δ5 | Reduction of Area ψ | Hardness (no heat treatment) |

| ≥410(42) Mpa | ≥245(25) Mpa | ≥25 % | ≥55 % | ≤156HB |

ABOUT US

- Q: How are steel round bars tested for tensile strength?

- Steel round bars are tested for tensile strength using a method called a tensile test. This test measures the resistance of a material to a stretching force, and it is commonly used to determine the mechanical properties of metals. To perform a tensile test on a steel round bar, a sample is taken from the bar in the form of a cylinder or a rectangular shape. The sample is then prepared by removing any surface imperfections or irregularities. Next, the sample is inserted into a testing machine called a tensile testing machine. The machine consists of two grips, one at each end, which securely hold the sample. One grip is fixed while the other is movable. The testing machine applies an increasing force to the sample, causing it to stretch until it eventually breaks. As the force is applied, the machine measures the amount of force required to stretch the sample and records the elongation or deformation of the sample throughout the test. The test results are used to calculate various mechanical properties of the steel round bar, including its ultimate tensile strength. This is the maximum amount of stress the material can withstand before it breaks. Other properties such as yield strength, elastic modulus, and elongation at break can also be determined from the test. Tensile testing is a critical method for determining the quality and suitability of steel round bars for various applications. It helps ensure that the material meets the required specifications and can withstand the expected loads and stresses in its intended use.

- Q: What are the common sizes of steel round bars?

- The specific application and industry standards determine the varying common sizes of steel round bars. Depending on these factors, the sizes can range from 1/4 inch to 24 inches in diameter. The availability of these sizes is often in increments of 1/8 inch or 1/4 inch. It is worth noting that the sizes may differ based on the country or region. Moreover, metric sizes are also an option, with diameters generally ranging from 6mm to 600mm. The extensive selection of steel round bar sizes enables a wide range of applications across different industries.

- Q: Can steel round bars be used for making fencing?

- Indeed, fencing can be made using steel round bars. In the construction industry, steel round bars find wide usage for diverse purposes, one of which is fencing. Thanks to its robustness and durability, steel proves to be an appropriate material for creating a strong and enduring enclosure. By welding or bolting steel round bars together, various fencing designs and configurations can be effortlessly formed. Moreover, steel can be galvanized or coated to augment its resistance against corrosion, rendering it suitable for outdoor fencing purposes. All in all, steel round bars are a versatile and dependable option for constructing fencing structures.

- Q: Are steel round bars suitable for electrical conductivity?

- Steel round bars are not typically known for their electrical conductivity. Steel is a good conductor of heat but has relatively poor electrical conductivity compared to other metals such as copper or aluminum. This is because steel is primarily composed of iron, which is a poor conductor of electricity. However, the electrical conductivity of steel can be improved by adding certain alloying elements such as chromium or nickel. These alloying elements can enhance the electrical conductivity of steel, making it more suitable for specific applications where electrical conductivity is required. Nonetheless, if high electrical conductivity is a critical requirement, other materials like copper or aluminum are usually preferred over steel round bars.

- Q: Can steel round bars be used in the manufacturing of bearings?

- Typically, steel round bars are not utilized in the production of bearings. Bearings necessitate materials with distinct qualities, such as exceptional strength, hardness, and resistance to wear. Steel round bars may not possess these attributes to the necessary extent. Instead, bearings are usually crafted from top-notch steel alloys that are specifically engineered for bearing purposes, such as bearing steel or stainless steel. These materials undergo specialized heat treatment procedures to attain the desired properties essential for bearing manufacturing, including the ability to bear heavy loads, minimal friction, and long-lasting endurance.

- Q: Can steel round bars be used for making fasteners or bolts?

- Certainly! The utilization of steel round bars is viable for the production of fasteners and bolts. Steel is widely employed as a material for these components due to its exceptional robustness, longevity, and resistance against corrosion. The round bars, crafted from steel, can be effortlessly manipulated and threaded, enabling the creation of an array of fasteners and bolts such as screws, nuts, and threaded rods. The selection of the precise steel grade hinges upon the specific application and desired strength properties. Nevertheless, it is imperative to bear in mind that the manufacturing process and stringent quality control are paramount in guaranteeing the dependability and performance of the end product.

- Q: How are steel round bars used in the construction of airports and runways?

- Steel round bars are commonly used in the construction of airports and runways due to their strength, durability, and versatility. These bars are primarily used in the reinforcement of concrete structures, ensuring that the airport infrastructure can withstand heavy loads and extreme weather conditions. In the construction of airport runways, steel round bars are commonly used to reinforce the concrete pavement. The bars are placed within the concrete during construction, providing additional tensile strength to the runway. This reinforcement helps to prevent cracking and crumbling under the weight of aircraft, ensuring a safe and reliable surface for landing and takeoff. Additionally, steel round bars are used in the construction of airport terminals and other buildings within the airport complex. They are often utilized in the framework of the structures, providing support and stability. The bars are commonly used in the construction of columns, beams, and foundations, ensuring the overall structural integrity of the buildings. Furthermore, steel round bars are employed in the construction of ancillary facilities such as hangars, control towers, and fuel storage facilities. These bars are used to reinforce the concrete foundations and walls, providing additional strength and stability to these critical structures. In summary, steel round bars are essential components in the construction of airports and runways. Their use reinforces concrete structures, providing the necessary strength and durability to withstand heavy loads and harsh environmental conditions. From runways to terminals and ancillary facilities, steel round bars play a crucial role in ensuring the safety and reliability of airport infrastructure.

- Q: How do you measure the diameter of a steel round bar?

- In order to determine the diameter of a steel round bar, there are two tools that can be utilized: a caliper or a micrometer. First and foremost, it is crucial to ensure that the round bar is devoid of any dirt, debris, or rough edges. Place the round bar on a level and smooth surface. If a caliper is available, open it and place one jaw on one side of the round bar and the other jaw on the opposite side. It is important to guarantee that the jaws are perpendicular to the bar and in contact with its outer surface. Gradually close the caliper until both jaws are firmly pressed against the bar. The measurement can be read from the caliper's scale or digital display, providing the diameter of the round bar. Alternatively, if a micrometer is at hand, open it and adjust the thimble to zero. Position the anvil, which is the stationary part, against one side of the round bar, and the spindle, which is the moving part, against the opposite side. Rotate the thimble until the spindle makes firm contact with the bar. The measurement can be read from the thimble's scale or digital display, along with the corresponding number on the barrel. This will yield the diameter of the round bar. It is important to remember that in order to ensure accuracy, multiple measurements should be taken at various points along the bar, as the diameter may not be perfectly uniform throughout its length.

- Q: Can steel round bars be machined easily?

- Yes, steel round bars can be machined easily due to their excellent machinability properties.

- Q: What are the corrosion resistance properties of steel round bars?

- Due to the presence of alloying elements like chromium, nickel, and molybdenum, steel round bars possess exceptional corrosion resistance. These elements combine to form a protective oxide layer on the steel's surface, effectively preventing contact with corrosive substances. By reacting with oxygen in the air, chromium in steel round bars forms a thin, unnoticeable layer of chromium oxide. This layer plays the role of a barrier, shielding the steel from further oxidation and corrosion. Additionally, nickel and molybdenum enhance the corrosion resistance of steel by increasing its ability to withstand pitting, crevice corrosion, and chloride-induced stress corrosion cracking. Apart from alloying elements, the manufacturing process can also impact the corrosion resistance of steel round bars. For example, stainless steel round bars are frequently subjected to passivation, a process that eliminates free iron and other contaminants from the surface. Passivation contributes to the steel's corrosion resistance by creating a clean and inert surface that is less susceptible to corrosion. In conclusion, steel round bars are renowned for their remarkable corrosion resistance, which makes them well-suited for a wide array of applications across various industries, including construction, marine, automotive, and aerospace.

Send your message to us

Carbon Structural Steel Round Bars SAE1018CR

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords