Carbon fiber shear

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mechanical Properties

| SFRC-0 | SFRC-1.0 | SFRC-1.5 | SFRC-2.0 |

Compressive strength Compressive strength(MPn) | 43.6 | 49.8 | 51.2 | 55.3 |

100% | 114.20% | 117.40% | 126.80% | |

Chop adn tension strength(MPn) | 3.74 | 4.89 | 5.7 | 6.58 |

100% | 129.90% | 152.40% | 175.90% | |

Bending strength with initial cracks(MPn) | 5.18 | 6.98 | 7.78 | 8.94 |

100% | 134.70% | 150.20% | 172.60% | |

Max.anti-deformation(MPa) | 5.6 | 9.4 | 10.7 | 13.9 |

100% | 167.80% | 191.10% | 248.20% | |

Toughness with initial cracks(Nmm) | 185.2 | 394.1 | 832.1 | 1161.1 |

100% | 212.80% | 449.30% | 627.00% |

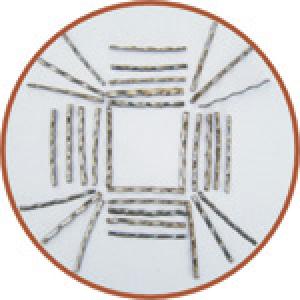

Application in projects

Project Type | Length(mm) | Diameter(equilavent diameter mm) | Length/Diameter |

Ordinarily laid steel fiber concrete | 20-60 | 0.3-0.9 | 30-80 |

Steel fiber injected concrete | 20-35 | 0.3-0.8 | 30-80 |

Steel fiber concrete with earthquake resistant frame joints | 35-60 | 0.3-0.9 | 50-80 |

Steel fiber concrete railway sleeper | 30-35 | 0.3-0.6 | 50-70 |

Laminated steel fiber concrete complex road surface | 30-120 | 0.3-1.2 | 60-100 |

- Q: What are the different types of stainless steel wire electrodes?

- There are several different types of stainless steel wire electrodes, including types 308, 309, and 316. These electrodes are distinguished by their chemical compositions, which determine their specific properties and suitability for different applications.

- Q: What are the different types of stainless steel wire for different levels of conductivity?

- There are several different types of stainless steel wire available, each with varying levels of conductivity. 1. Austenitic Stainless Steel Wire: This type of stainless steel wire is commonly used in applications that require a high level of corrosion resistance. While it offers good mechanical properties, it has a relatively low electrical conductivity compared to other types of stainless steel wire. 2. Ferritic Stainless Steel Wire: Ferritic stainless steel wire is known for its magnetic properties and offers good resistance to corrosion. However, it has a lower electrical conductivity compared to austenitic stainless steel wire. 3. Martensitic Stainless Steel Wire: Martensitic stainless steel wire is characterized by its high strength and hardness. It has moderate corrosion resistance and relatively low electrical conductivity. 4. Duplex Stainless Steel Wire: Duplex stainless steel wire combines the properties of both austenitic and ferritic stainless steels. It offers good corrosion resistance and moderate electrical conductivity. In general, if high electrical conductivity is a requirement, other materials like copper or aluminum wires may be more suitable. However, stainless steel wires can still be used in certain applications where corrosion resistance and durability are more important factors.

- Q: What are the common applications of stainless steel wire?

- Stainless steel wire has a wide range of applications due to its unique properties. It is commonly used in industries such as construction, automotive, aerospace, and electronics. Some common applications include wire mesh for filtration and sieving purposes, reinforcement in concrete structures, fencing and security barriers, electrical wiring, and cable ropes. Additionally, stainless steel wire is used in medical devices, kitchen utensils, and jewelry, thanks to its corrosion resistance and aesthetic appeal.

- Q: Can stainless steel wire be used for wire bending?

- Yes, stainless steel wire can be used for wire bending. Stainless steel is a strong and durable material that can be easily manipulated and shaped without breaking, making it suitable for various wire bending applications.

- Q: What are the different types of stainless steel wire surface finishes?

- Different types of surface finishes are available for stainless steel wire, each with its own unique characteristics and advantages. Some of the most commonly used finishes are as follows: 1. Achieving a highly reflective and smooth surface, the Bright Annealed (BA) Finish involves annealing the stainless steel wire in a controlled atmosphere. It is frequently utilized for decorative purposes, where a shiny and visually appealing look is desired. 2. Known as a hot-rolled annealed and pickled (HRAP) finish, the No. 1 Finish is obtained through hot rolling, followed by annealing and pickling. It exhibits a dull and rough appearance, often preferred for industrial applications where aesthetics are not a primary concern. 3. For a smooth and even appearance, the No. 2B Finish is attained by cold rolling the wire, followed by annealing and descaling. It displays a moderately reflective surface and finds common usage in applications such as kitchen appliances and architectural components. 4. The No. 4 Finish is achieved by progressively polishing the wire with finer abrasives until a uniform and smooth surface is obtained. It presents a brushed appearance and is commonly employed in applications where both aesthetics and functionality hold importance, such as elevator doors and decorative elements. 5. Referred to as a mirror or reflective finish, the No. 8 Mirror Finish involves further polishing the wire to achieve a highly reflective and mirror-like surface. It is often utilized in decorative applications, where a high-end and luxurious appearance is desired. 6. The Electro-Polished (EP) Finish entails subjecting the wire to an electrochemical process that eliminates surface imperfections and enhances corrosion resistance. This process produces a smooth and bright surface finish, making it a popular choice in industries where hygiene and cleanliness are critical, such as pharmaceutical and food processing. It should be noted that the choice of the appropriate surface finish depends on several factors, including the intended application, desired appearance, and specific requirements of the wire.

- Q: How does stainless steel wire resist staining?

- Stainless steel wire possesses exceptional resistance to staining due to its unique chemical composition and surface properties. Its ability to resist stains is primarily attributed to the presence of chromium, which forms a thin layer of protective oxide on the wire's surface. This protective layer, known as the passive layer, acts as a barrier, preventing the penetration of oxygen and moisture into the underlying metal. Moreover, the passive layer has the remarkable ability to self-heal. In the event of any damage or scratches, it can swiftly regenerate and restore its protective qualities. This inherent capability to self-repair significantly contributes to the overall stain resistance of stainless steel wire. Furthermore, stainless steel wire frequently incorporates additional alloying elements like nickel and molybdenum, which further enhance its resistance to staining. These elements not only augment the wire's corrosion resistance but also enable it to withstand exposure to various chemicals and environments. Additionally, the smooth and non-porous surface of stainless steel wire plays a crucial role in its stain resistance. Unlike other materials, stainless steel wire lacks microscopic cracks or pores that could trap and retain staining substances. Consequently, it is easier to clean and maintain its appearance over time. In conclusion, the exceptional stain resistance of stainless steel wire can be attributed to a combination of factors, including chromium content, presence of other alloying elements, self-repairing properties, and smooth surface. These qualities make stainless steel wire the preferred choice for a wide range of applications where aesthetics and durability are of utmost importance.

- Q: What are the different types of stainless steel wire ropes used in agriculture?

- In agriculture, there exists a variety of stainless steel wire ropes that serve different purposes and possess distinct characteristics. 1. The 6x19 Class Wire Rope, for instance, is composed of 6 strands, with each strand containing 19 wires. It finds its common usage in agricultural activities like fencing, vineyard trellising, and orchard support. Thanks to its strength and flexibility, it can handle heavy loads and provide stability. 2. Similarly, the 7x19 Class Wire Rope also consists of 7 strands with 19 wires in each. It offers increased flexibility and is often employed in agricultural machinery and equipment, such as pulley systems and winches. Due to its durability and versatility, it is well-suited for various agricultural operations. 3. In contrast, the 1x19 Class Wire Rope is constructed using a single strand tightly wound with 19 wires. It is frequently utilized in agricultural applications that require both high strength and minimal stretch, such as animal enclosures and livestock handling equipment. Its rigid structure ensures stability and reliability. 4. Another type of wire rope is the 7x7 Class Wire Rope, which consists of 7 strands, each containing 7 wires. It is commonly found in agricultural activities that necessitate moderate strength and flexibility, such as greenhouse construction, shade netting, and crop support systems. Its pliable nature allows for easy installation and adjustment. 5. Lastly, the 7x19 Vinyl Coated Wire Rope is coated with vinyl, providing an additional layer of protection against corrosion and wear. It is extensively used in agricultural applications that demand resistance to harsh weather conditions, for example, outdoor fencing, animal enclosures, and trellis systems. The vinyl coating also aids in reducing potential damage to crops or livestock. To ensure the appropriate selection of stainless steel wire rope for agricultural purposes, several factors must be considered, including load requirements, environmental conditions, and desired flexibility.

- Q: What are the different types of stainless steel wire fasteners?

- A variety of stainless steel wire fasteners can be found on the market, offering different options for various needs. Some commonly used types include: 1. Stainless steel screws: These fasteners have threads and are used to join objects together. They come in different lengths, diameters, and head styles to accommodate different applications. 2. Stainless steel bolts: Similar to screws, bolts are threaded fasteners, but they usually have a larger diameter and require a nut to secure the joint. They are commonly used in heavy-duty situations. 3. Stainless steel nuts: Nuts are used together with bolts to secure joints. They come in various shapes and sizes, such as hexagonal, square, and winged nuts. 4. Stainless steel washers: Washers are thin, flat metal discs used to evenly distribute load and protect the material's surface. They come in different sizes and shapes, including flat washers, lock washers, and fender washers. 5. Stainless steel rivets: Rivets are permanent fasteners inserted into materials, deforming the end to join them together. They are commonly used in industries like automotive, aerospace, and construction. 6. Stainless steel clips and clamps: Clips and clamps are used for securing or holding objects in place. They come in various designs, such as spring clips, hose clamps, and pipe clamps. 7. Stainless steel nails: Nails are pointed fasteners used in woodworking and construction to secure materials together. 8. Stainless steel pins: Pins are cylindrical fasteners used to hold components or align parts together. They come in different shapes, like dowel pins, cotter pins, and hitch pins. 9. Stainless steel hooks: Hooks are curved fasteners used for hanging or suspending objects. They are commonly used in applications such as hanging plants, tools, or decorative items. It should be noted that these examples are just a small selection of the stainless steel wire fasteners available. The specific choice of fastener will depend on factors like the application, load requirements, and environmental conditions.

- Q: How long does stainless steel wire last?

- Stainless steel wire is known for its excellent durability and corrosion resistance, making it a highly reliable option for various applications. The lifespan of stainless steel wire can vary depending on several factors such as the environment it is exposed to, the quality of the stainless steel used, and the level of maintenance it receives. However, on average, stainless steel wire can last for several decades, if not more. In indoor or non-corrosive environments, stainless steel wire can last indefinitely without showing any signs of degradation. In more aggressive environments, such as marine or industrial settings, the lifespan of stainless steel wire can be reduced, but it still outperforms other materials. Regular cleaning and maintenance can significantly prolong the life of stainless steel wire and ensure its continued functionality and aesthetic appeal. Overall, stainless steel wire is renowned for its longevity, making it a cost-effective choice for a wide range of applications.

- Q: What are the different types of stainless steel wire rope thimbles?

- There is a wide variety of stainless steel wire rope thimbles available in the market, each serving specific needs and applications. The designs and constructions of these thimbles vary. The first type is the standard thimbles, which are commonly used in different industries. They are made of stainless steel and have a simple design with a smooth surface. These thimbles provide basic protection and support to the wire rope, preventing any damage or fraying. Next, we have the heavy-duty thimbles that are specifically designed to withstand higher loads and offer increased strength and durability. They are commonly utilized in heavy lifting or rigging scenarios where the wire rope is exposed to extreme stress or tension. Open thimbles come with a gap or opening on one side, enabling easy installation or replacement of the wire rope. They are frequently used when the wire rope needs frequent adjustments or changes. For added protection against corrosion and abrasion, there are plastic-coated thimbles. These thimbles have a plastic coating or sleeve that extends the lifespan of the wire rope by preventing direct contact with moisture or harsh chemicals. Wire rope clip thimbles consist of both a thimble and a wire rope clip, working together to securely fasten the wire rope in place. They are commonly employed in applications where preventing slippage is crucial. Lastly, we have swage thimbles that are crimped or swaged onto the wire rope, creating a strong and permanent attachment. They are commonly used when a reliable and secure connection is required. To ensure you choose the most suitable stainless steel wire rope thimble for your specific needs, it is essential to consider the requirements of your application and consult with a knowledgeable supplier or engineer.

Send your message to us

Carbon fiber shear

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords