430 Stainless Steel Wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

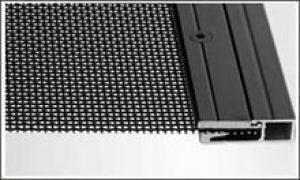

Stainless Steel Wire

1.Grade: SS 200,300,400 series

2.Dia: 0.1mm-100mm

3.Length:500m-2000m/Reel

4.Surface: Bright

5.Certificate: Fortune 500, SGS, ISO 9001:2008

6.Test: Salt Spray over200 hours

7.MOQ:500kg

8.Delivery: Within 20 days

9.Packing: Reel, wooden box or according to your requirement

10.Payment terms: China Main Port or CIF ANY PORT

11. Application: Tie wire, pins, lashing, forming wire, filters, gaskets, elevators, safety wire, shaped and flat wire, conveyors, jewelry, springs, brush welding, electrical, wire line, craft and many more applications.

|

Main Grades |

C % |

Si % |

S % |

P % |

Mn % |

Cr % |

Ni % |

Mo % |

Cu % |

|

S30400 |

<0.08 |

<0.75 |

<0.015 |

<0.045 |

<2 |

18.05-19 |

8.01--8.25 |

<0.6 | |

|

304H |

0.04-0.1 |

<0.75 |

<0.015 |

<0.045 |

<2 |

18.05-19 |

8.01--8.25 |

<0.5 | |

|

304Hc1 |

0.03-0.05 |

<0.75 |

<0.015 |

<0.045 |

<2 |

18.05-19 |

8.01-8.25 |

1.2-1.6 | |

|

304Hc |

0.03-0.05 |

<0.75 |

<0.015 |

<0.045 |

<2 |

18.05-19 |

8.01--8.25 |

2-3 | |

|

304Hc3 |

0.03-0.05 |

<0.75 |

<0.015 |

<0.045 |

<2 |

18.05-19 |

8.01--8.25 |

3-3.5 | |

|

304ES |

<0.08 |

<0.75 |

<0.015 |

<0.045 |

2-3 |

16.05-17 |

6.01-6.3 |

1.5-3 | |

|

304M2 |

0.05-0.08 |

<0.75 |

<0.015 |

<0.045 |

2-3 |

18-18.5 |

7-8.1 |

<0.6 | |

|

304M3 |

0.05-0.08 |

<0.75 |

<0.015 |

<0.045 |

2-3 |

18-18.5 |

8.01-8.25 |

<0.6 | |

|

304L |

<0.035 |

<0.75 |

<0.015 |

<0.045 |

<2 |

18.05-19 |

8.01--8.25 |

<0.6 | |

|

321 |

0.04-0.08 |

<0.75 |

<0.015 |

<0.045 |

<2 |

17-18 |

8.01--8.25 |

||

|

316L |

<0.035 |

<0.75 |

<0.015 |

<0.045 |

<2 |

16.05-17 |

10.01--10.35 |

2.01-2.2 |

<1 |

|

316 |

0.04-0.08 |

<0.75 |

<0.015 |

<0.045 |

<2 |

16.05-17 |

10.01--10.35 |

2.01-2.2 |

<1 |

|

316LCu |

<0.035 |

<0.75 |

<0.05 |

<0.045 |

<2 |

16-17 |

10-10.5 |

2-2.25 |

|

|

ER316L |

<0.04 |

0.65 |

<0.03 |

<0.04 |

1.0-2.5 |

18-20 |

11.1-12 |

||

|

201CU |

<0.08 |

<0.75 |

<0.015 |

<0.045 |

8-9.5 |

13.05-14 |

4.01-4.25 |

2-3 | |

|

D667 |

<0.08 |

<0.75 |

<0.015 |

<0.045 |

13-14 |

13-14 |

0.7-1.5 |

1.5-3 | |

|

D665B |

<0.08 |

<0.75 |

<0.015 |

<0.045 |

14-16 |

10.05-11 |

<1.2 |

0.5--1.5 | |

|

202B |

0.1-0.15 |

<0.75 |

<0.015 |

<0.045 |

9-10 |

17.05-18 |

4.5-5 |

||

|

D669 |

0.08-1.0 |

<0.75 |

<0.015 |

<0.045 |

14.5-16 |

11-12 |

<1.2 |

0.5-1.5 | |

|

200CU |

<0.08 |

<0.75 |

<0.015 |

<0.045 |

11-12 |

13-14 |

1-2 |

1.5-2.5 |

- Q: Is it necessary to make barbecue with argon arc welding wire (stainless steel)?

- Because the composition of stainless steel wire itself is higher than stainless steel purity, high-grade, and ordinary stainless steel nowCan also be used in the medical, food machinery industry.

- Q: Can stainless steel wire be used for wire forms?

- Yes, stainless steel wire can be used for wire forms. Stainless steel is a versatile and durable material that can be easily shaped into various forms, making it suitable for a wide range of applications including wire forms. It offers excellent corrosion resistance, strength, and flexibility, making it an ideal choice for creating wire forms that require durability and longevity.

- Q: Can stainless steel wire be used for jewelry-making?

- Yes, stainless steel wire can be used for jewelry-making. It is a popular choice due to its durability, resistance to tarnishing, and affordability. Stainless steel wire allows for the creation of various types of jewelry such as necklaces, bracelets, and earrings.

- Q: Can stainless steel wire be used for cable railing?

- Yes, stainless steel wire can be used for cable railing. In fact, it is one of the most popular materials used for this purpose. Stainless steel wire offers several advantages for cable railing systems. Firstly, it is highly durable and resistant to corrosion, which makes it suitable for outdoor applications where it may be exposed to different weather conditions. Additionally, stainless steel wire provides a sleek and modern aesthetic, making it a popular choice for contemporary architectural designs. Furthermore, stainless steel wire is strong and can withstand the tension required for cable railing systems, ensuring the safety and stability of the railing. Overall, stainless steel wire is an excellent choice for cable railing due to its durability, aesthetic appeal, and strength.

- Q: Can stainless steel wire be used for fishing tackle?

- Yes, stainless steel wire can be used for fishing tackle. Stainless steel wire is known for its strength, durability, and resistance to corrosion, making it a popular choice for various fishing applications. It is commonly used to make leaders, which are the sections of line that connect the main fishing line to the hook or lure. Stainless steel wire leaders are particularly useful when targeting predatory fish species with sharp teeth or abrasive mouths, as they provide a tough and reliable barrier against bite-offs. Additionally, stainless steel wire can also be used to make fishing rigs, such as spreader bars or wire traces, which are used in certain fishing techniques. However, it is important to note that the specific type and thickness of stainless steel wire used should be suitable for the target fish species and fishing conditions to ensure optimal performance and safety.

- Q: Can stainless steel wire be used for musical instrument strings?

- Yes, stainless steel wire can be used for musical instrument strings. In fact, stainless steel is a popular choice for guitar, piano, and other string instrument strings due to its durability and corrosion resistance. Stainless steel strings offer a bright and crisp tone, making them suitable for various musical genres. They also tend to have a longer lifespan compared to other materials like nickel or bronze. However, it's worth noting that the choice of string material ultimately depends on the instrument and the desired sound, so it's always recommended to consult with a professional or experiment with different types of strings to find the best fit for a specific musical instrument.

- Q: What are the typical packaging options for stainless steel wire?

- The typical packaging options for stainless steel wire can vary depending on the manufacturer and the specific requirements of the customer. However, there are some common packaging options that are commonly used in the industry. One of the most common packaging options for stainless steel wire is spools. Spools are cylindrical containers made of plastic or metal, with the wire wound around them. Spools are convenient for storing and transporting stainless steel wire, as they prevent tangling and allow for easy unwinding during usage. They come in various sizes and can accommodate different lengths and diameters of wire. Another packaging option is coils. Coils are similar to spools, but instead of being wound on a cylindrical container, the wire is wound into a circular shape directly. Coils are commonly used for smaller quantities of stainless steel wire or for thicker gauges where spools may not be practical. Coils are often wrapped with plastic or paper to protect the wire during transportation and storage. In addition to spools and coils, stainless steel wire can also be packaged in bundles. Bundles are groups of wire tied together using straps or wires. Bundles are typically used for larger quantities of wire or for thicker gauges that cannot be easily wound onto spools or coils. They are often wrapped with plastic or metal sheets to provide protection during storage and transportation. Furthermore, some manufacturers may also offer custom packaging options based on specific customer requirements. This can include packaging stainless steel wire in boxes, crates, or on pallets, depending on the quantity and dimensions of the wire. Overall, the typical packaging options for stainless steel wire include spools, coils, and bundles. These packaging options are designed to ensure the safe storage, transportation, and usage of stainless steel wire while minimizing tangling and damage.

- Q: Can stainless steel wire be used for weaving?

- Yes, stainless steel wire can be used for weaving. Stainless steel wire is known for its strength, durability, and corrosion resistance, making it an excellent choice for various weaving applications. It can be woven into different patterns, such as plain weave, twill weave, or satin weave, to create different textures and designs. Stainless steel wire can be used for weaving various items, including baskets, jewelry, wire mesh screens, and even intricate artworks. Additionally, its resistance to heat and chemicals makes it suitable for weaving projects that require exposure to extreme conditions.

- Q: What are the different sizes available for stainless steel wire?

- There are various sizes available for stainless steel wire, ranging from very thin diameters, such as 0.001 inches or 0.0254 millimeters, to thicker gauges, such as 0.250 inches or 6.35 millimeters. The specific sizes available depend on the manufacturer and the intended application of the wire.

- Q: Can stainless steel wire shelves be used for storage in wet environments?

- Yes, stainless steel wire shelves can be used for storage in wet environments. Stainless steel is highly resistant to corrosion and rust, making it ideal for use in areas with high moisture or humidity levels. It is a durable and hygienic material that can withstand exposure to water without deteriorating or causing any damage to the stored items.

Send your message to us

430 Stainless Steel Wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords