Cantilever Formwork with Remarkable Performances and Trustful Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

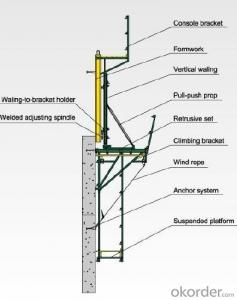

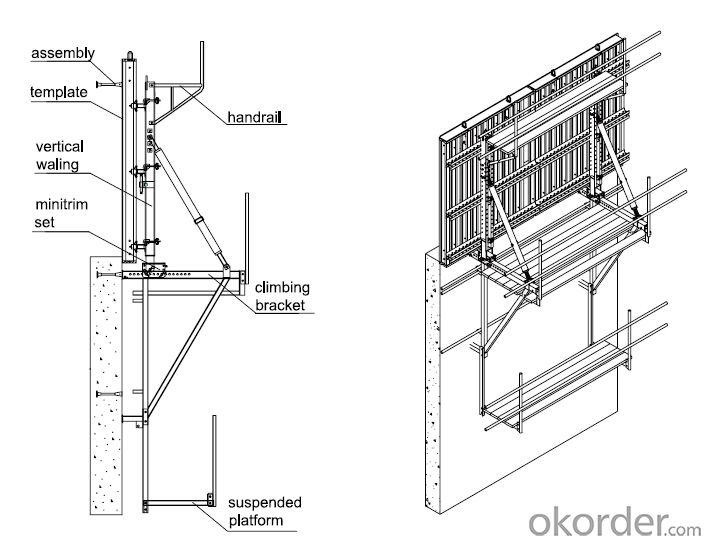

1. Structure of Cantilever Formwork Description

Cantilever Formwork is mainly used in the concrete pouring of pier, high buildings, and so on. The concrete lateral pressure is entirely supported by anchor system and the wall-through tie-rods, additional reinforcement is not needed. The construction is easy, rapid and economical. A single pouring height is high and the finished concrete surface is perfect. Cantilever formwork has several types, the structure is similar, and has its own different characteristic. Can use them according to actual demand.

Main cantilever Formwork:PJ200 & PJ240,CB-240 etc.

2. Main Features of Cantilever Formwork

-easy to assemble

-simple structure.

-easy, rapid and economical.

3. Cantilever Formwork Images

4. Cantilever Formwork Specifications

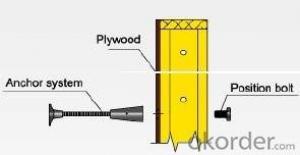

Anchor system

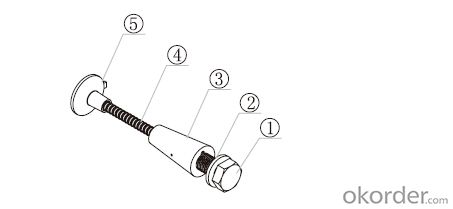

Anchor system is the most important supporting part. The system is made of five parts shown below. There into, tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusing after the concrete pouring.

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤Ancor plate D15

5.FAQ of Cantilever Formwork

1) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

2) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

- Q: Steel tube scaffolding construction labor time? Whether the demolition of construction

- And can be roughly divided as follows: 2.1 according to the material of the bar1) single specification steel pipe scaffold. It only uses a steel pipe specifications, such as steel tubular scaffolding, welded steel pipe using only 48 * 3.5.2) a variety of specifications of steel pipe scaffolding. The utility model is composed of two or more steel pipes of different specifications, such as a door type scaffold. 3) steel tubular scaffolding. As to the steel pipe, and combined with other type of steel pieces composed of scaffolding, such as the channel has a base in the backwater or scaffolding, connecting steel scaffolding and so on.

- Q: In the first scaffold scene, which is at the beginning of the book with Hester's sentencing of three hours on the scaffold. This is when Pearl is still a baby. And the last scene where things are being revealed at the end of the book. What time of day are both of those? Like afternoon, evening; month; season, etc. Do you guys have any info about that? It doesn't have to be all I listed just something that says the time they occurred.Thanks.:)

- At the beginning of the Market Place chapter..it starts off with The grass plot before the jail, in Prison Lane, ona certain summer morning.... so that one is morning and in the summer and the last one....is probably in mid morning b/c its after a sermon and also..i think in the forest chapter it says something about it being in autumn *.*

- Q: I want to talk my mum into it.She might let me because it fits my school's regulations (two piercings/earrings per ear) but she might not because the holes are permanentI was wondering if the holes you get are a certain size, they might close up if you don't wear the earring for a while?And also, I'd like to know some health risks associated to getting one.Thanks.

- The okorder for more info on industrials. There are plenty of personal experience stories and information on them. Keep in mind that industrials take 6 months to a year to heal and you will need to take special care durring that time. If its worth the work to you, enjoy your piercing =)

- Q: What's your opinion of them?

- love , i think they look really good.

- Q: What were Hester's three appearances on the scaffold?1 was prosecution and another was dimmesdale's death and confession. What was the third?

- I think that's where she meets Dimmesdale at night with their daughter, and they watch the comet fly over their heads. She was coming back, from doing work with her needlework (it's either the gloves or the shroud, if that helps). Dimmy sees her, they meet, and the red comet shoots by. The residents thing that it means Angel, since I think that it made an A shape in the sky.

- Q: Why does this discovery both confuse and frighten her?quot;The Scarlet Letterquot;

- her husband, he has been in England while she was in America for a year or 2 can't remember; I think she thought he was dead or not coming cannot remember. It frightens her because she has a kid that cannot be his.

- Q: Okay, so I got a scaffolding/industrial piercing today I'm really happy with it. Now all I'm wondering about is cleaning it. People have recommended that I bathe it in salt solution for a few minutes each day to keep it clean soothe it. I have a couple little syringes, minus the needles, that my dad brought home from work, (he's a nurse). They are completely sterile, infact new out of the packet. Would squirting the salt solution directly onto the piercing wounds be equally good to clean it ? Or does anyone else have any suggestions for taking care of said piercings ?

- nonono, industrials or infamous for infections. in case you do no longer sparkling it, think of how lots bacteria is going to be close to it considering all of the folds of the ear and the oils or your hair. I sparkling my business a minimum of two times on an primary basis, and that i've got yet to get an infection although. What I do is Sea Salt Soaks interior the morning and nighttime. I placed a sprint emu oil to advoid hypertrophic scarring. and that i've got saved my hair up on a daily basis considering getting it pierced to confirm my hair does not worsen it jointly as its nevertheless in its early healing section.

- Q: What is the previous version of the scaffold fastener (JGJ166-2008) for construction? That is, the implementation of the current version of JGJ166-2008 will soon be replaced by 2009.7.1 version.

- What does the previous version mean? Once the new version comes out, the previous version is cancelled

- Q: Cost of rent per day per month per ton of scaffolding

- The rent of the wheeled scaffold varies from place to place, with different regions

- Q: Standard Specification for steel tubes for ladder type scaffolding

- 1, multi function: the construction according to the specific requirements of different groups composed of frame sizes, shapes and bearing capacity of single and double row scaffolding, supporting frame, support columns, material lifting frame, climbing scaffolding, cantilever frame construction equipment and other function. Can also be used to set up construction shed, shed, lighthouse and other structures. The utility model is especially suitable for building curved surfaces and heavy load support frames.2, high efficiency: commonly used rod in the longest 3130mm, weight 17.07kg. The speed of the whole frame is 3 to 5 times faster than that of the conventional one, and the assembling and disassembling is quick and labor-saving, and the workers can complete all the operations with a hammer, which avoids the inconvenience caused by the bolt operation.3, versatility: the main components are the use of ordinary fastener type steel pipe scaffolding, can be used with ordinary steel pipe connection, universal.

Send your message to us

Cantilever Formwork with Remarkable Performances and Trustful Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords