Cantilever Formwork with Great Performnce and Trustful Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

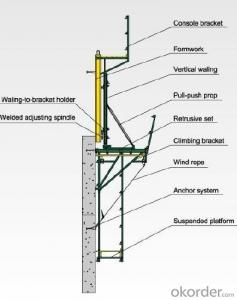

1. Structure of Cantilever Formwork Description

Cantilever formwork is used in dams, piers, retaining wall and cooling tower etc. All the concrete side-pressure is borne by the anchors and the brackets. As there is no through-wall tie-rod, the concrete is very clean.

The formwork can be moved backward by 600mm for cleaning the formwork and fixing the reinforcing steel bar. Waler connector is used for connecting the form to ensure form alignment.

Form can be pushed to the already cast concrete by turning the adjust carriage to avoid concrete offset or leakage.The formwork can be moved freely as you request. The formwork can be inclined backward and forward. Max. angle: 30°. High standard elements can be widely used.

2. Main Features of Cantilever Formwork

-easy to assemble

-simple structure.

-easy, rapid and economical.

-Economical and safe anchoring

The M30/D20 climbing cones have been designed especially for single-sided concreting using cantilever formwork in dam construction, and to allow the transfer of high tensile and shear forces into the still fresh, unreinforced concrete. Without wall-through tie-rods, finished concrete is perfect.

3. Cantilever Formwork Images

4. Cantilever Formwork Specifications

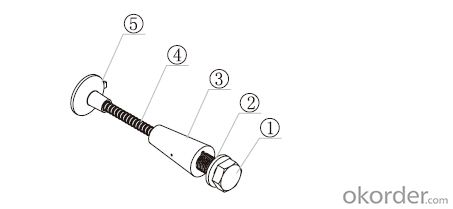

Anchor system

Anchor system is the most important supporting part. The system is made of five parts shown below. There into, tensile bolt, anchor shoe and bowl-climbing cone can be taken out for reusing after the concrete pouring.

① Tensile bolt M30/L= 110

② Anchor shoe

③ Bowl-climbing cone M30/D15

④ High-strength rod D15

⑤Ancor plate D15

5.FAQ of Cantilever Formwork

1) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

2) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

- Q: What is the height limitation of the standing braces in ringlock scaffolding system?

- Hi addla, I do not know, but I am sure you do and please tell us all addla.

- Q: Single double scaffolding distinctionPlease list the sketch map

- Single row of scaffolding is generally used for internal wall plastering, brush paint, and so do not need to bear the work of a single row of scaffolding need to hold the pole against the wallChinese now used in the steel pipe scaffold material made of steel tubular scaffolding, bowl button steel scaffolding, socket type steel pipe scaffolding, scaffolding doors, and every kind of the scaffolding, hanging scaffold steel pipe scaffolding and other materials. The materials and structures to proceed, and can be roughly divided as follows:Material division according to bar

- Q: What is the difference between the bowl buckle steel tube scaffold and the steel pipe scaffold

- (6) the main component is welded with the steel pipe with the diameter of * * * 3.5, Q235, the manufacturing process is simple, the cost is moderate, and the existing fastener type scaffolding can be directly processed and reformed without complicated processing equipment.(7) it is not easy to lose: the scaffold is not easy to lose the fastener, reduce the loss to the minimum degree.(8) repair less: the scaffolding component eliminates the bolt connection. The components are subject to impact resistance. The general corrosion does not affect the demolition operations, without special maintenance, maintenance;

- Q: Buckle scaffolding problem, now used more or less? Why don't we use it?

- We're all talking about wooden scaffolding! But also very easy to use ah

- Q: Can you shorten the distance of the bowl buckle scaffold? That is, regardless of the length of the pole, the distance can be set to 60, 90, 120cm. Thank you

- Must be 120 steps according to the distance control, set up close to the bottom plate beam always available for 60 or 90 bars and the adjustable bracket is adjusted.

- Q: Bowl buckle scaffold theory weight table who has, the distance is how much?

- The bridge supports the use of bowl buckle scaffold in the majority, but also the use of portal scaffolding

- Q: why the scaffold nned to be inspected within the preceding seven(7) days?

- To make sure that it is constructed properly and things haven';t slipped out

- Q: Bowl buckle type steel pipe scaffold and full fastener type scaffolding are long what kind of? What is the difference

- In general, all scaffolding are used to build a bowl buckle scaffold, and rarely use fastener scaffolding to take,

- Q: The latest version of the external scaffolding erection norms and template engineering construction quality acceptance specification which two ah? Thank you

- . No nameSpecification for "template engineering construction quality acceptance specification". Template engineering construction quality acceptance requirements, in GB50204-2015 "concrete structure engineering construction quality acceptance specification".

- Q: Why does this discovery both confuse and frighten her?quot;The Scarlet Letterquot;

- her husband, he has been in England while she was in America for a year or 2 can't remember; I think she thought he was dead or not coming cannot remember. It frightens her because she has a kid that cannot be his.

Send your message to us

Cantilever Formwork with Great Performnce and Trustful Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords