Calcium Silicate Insulation Block Sheet Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Calcium Silicate Boards) Description

1.Obtained CE, KR and ISO9001;

2.Heat resistance temperature is up to 1100 degree centigrade;

3.Low price and best quality.

Description of our products

Calcium Silicate Board is a kind of high efficiency energy-saving and Environmentally friendly materials with temperature limited 1150 cent-degree. They are recommended as thermal insulations of equipment in power station, steel mill and petrochemical industries as well as other various fields. It can be used in washrooms as the ceiling, partition and backer boards. Additionally, Due to the features of fire prevention, thermal insulation, mildew proof and moisture proof, are also applicable to places where high security is needed.

Advantages of our products

1. we have own factory to produce the boards, and we are not the trading company, so we would have the directly customer service and the warranty of our boards is very good;

2. We obtained CE, KR and ISO9001;

3. The highest heat resistance temperature is up to 1100 degree centigrade;

4.The maximum flexural strength is up to 0.7MPa, all technical parameters are the best in China, it is better than other calcium silicate board in the market.

5.Our factory is corporate with the big power plant, uses the steam of the power plant to product the board, it is different from other factories to produce with the boiler. The product use the steam, the quality is better than use the boiler, so the technical parameters of our product are the best in factory. And it is very easy to mass product and reduce the waste, the cost is lower than our factory use boiler. So that the product from our factory is best quality and cheapest price.

2,Main Features of the (Calcium Silicate Boards)

Types of products

1. Standard type Calcium Silicate Board

2. JN High-temp Type Calcium Silicate Board

3. High density Calcium Silicate Insulation material Board

4. High strength calcium silicate boards

5. Core Board of Fire Door

6.External wall calcium silicate board

7.Thermal insulation pipe cover

8. Light weight low thermal conductivity calcium silicate board 130kg/m³

Product advantage :

Excellent chemical stability

Low thermal conductivity;

Low heat capacity;

Excellent sound absorption and noise reduction performance

Physical performance data:

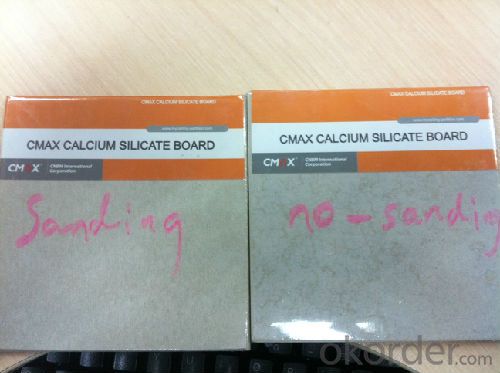

3,(Calcium Silicate Boards) Images

4,(Calcium Silicate Boards) Specification

Physical tech datas | 170 | 220 | 240 |

Density(kg/m3) | 170 | 220 | 240 |

Quality moisture content(%) | ≤7.5 | ≤7.5 | ≤7.5 |

Compressive strength(Mpa) | ≥0.40 | ≥0.50 | ≥0.50 |

Flexural strength(Mpa) | ≥0.20 | ≥0.30 | ≥0.30 |

Termal conductivity(W/m.k) | 0.058 | 0.062 | 0.062 |

Work temperature | 650 | 650 | 650 |

Linear shrinkage(%) | ≤2 | ≤2 | ≤2 |

Size | 600*300*25-100mm, 500*500*25-100mm | ||

Length(±3 mm) mm | Width(±3 mm) mm | thickness(+2 mm-1.5mm) |

1260 | 1260 | 50--120 |

1000 | 500 | 50--120 |

600 | 400 | 40--120 |

600 | 300,150 | 30--140 |

500 | 500 | 50--120 |

400 | 250 | 25--140 |

Products with max. service temp. of 1050°C are also available here.

5,FAQ of (Calcium Silicate Boards)

Application:

Petrochemical industry

Iron & steel industry

Cement industry

Glass industry

Shipping industry

- Q: Calcium silicate board is not asbestos?

- Some, that is, "no asbestos calcium silicate board." The fiber mainly uses paper fibers instead of asbestos, but relatively speaking, the strength will be lower. If you are helpful, please add points.

- Q: Paper gypsum board, calcium silicate board, silicon calcium board difference

- Gypsum board is built with gypsum (that is, CaSO4) as the main raw material, mixed with the right amount of additives (adjust the rate of condensation) and fiber to do the core, with a special plate for the face, the processing of the plate. High, impatient

- Q: What is calcium silicate board?

- Part of my finishing part of the hair you see: fiber reinforced calcium silicate board (referred to as calcium silicate board) is inorganic mineral fiber or cellulose fiber and other loose fiber as a reinforcing material to calcium - siliceous material as the main cementing material , By the pulp, into the blank and high pressure steaming and other processes made of new environmentally friendly energy-saving sheet.

- Q: There is no material similar to calcium silicate board. Can replace the calcium silicate board. Texture is almost the same?

- What is the use of the ceiling or wall? If you do ceiling, then, or calcium silicate board cost-effective. If you do the wall, then you can use cement board instead, similar performance, but the cement board to be slightly more expensive.

- Q: Calcium silicate board fire board can do air conditioning ducts do

- Yes, apply 93 decorative quota: 3-84 fire board attached to the wood base layer (the most appropriate) other related: 2-150 fire board wood keel base wall wall skirt 2-160 fire board wood keel base beam and column.

- Q: I need a tool that can cut calcium silicate board, Bo deep good, where can I buy Wuxi?

- Bo deep specifically for the development of calcium silicate special saw blade, the company used it, the effect is good, the tool does not know if they have

- Q: Calcium silicate board can be ground?

- Yes, you can ceiling, floor, etc. are possible, calcium silicate board light, waterproof, sound absorption is very easy to use

- Q: What is the difference between perforated calcium silicate wallboard and gypsum board?

- Perforated calcium silicate wallboard as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, in the practical use of a wide range of applications. Our unit is used in Jiangsu Sanxian Architectural Acoustics System Co., Ltd. production of perforated calcium silicate wallboard.

- Q: Will silicon calcium plate become moldy?

- Calcium silicate mainly composed of calcium silicate, composed of siliceous materials (diatomaceous earth, bentonite, quartz powder, etc.), calcium material, reinforced fiber as the main raw material, after pulping, billet, steam curing, And other processes made of lightweight plate.

- Q: What is the difference between calcium silicate board and mineral wool board?

- Mineral wool board mineral wool dust particles are easy to inhale the human body, and is a high carcinogen. Silica calcium board is the name of the fiber reinforced calcium silicate board, which is made of siliceous materials (diatomaceous earth, bentonite, quartz powder, etc.), calcium material, reinforced fiber as the main raw material, after pulping, Support, surface sanding and other processes made of lightweight sheet. Silicon calcium board light, high strength, moisture, corrosion, easy processing, not as mineral wool board that can not be processed In terms of health and environmental protection, mineral wool board mineral wool dust particles are easy to inhale the human body, and high carcinogenic substances;

Send your message to us

Calcium Silicate Insulation Block Sheet Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords