Butterfly Valve DN700 BS5163 with Hand Wheel Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

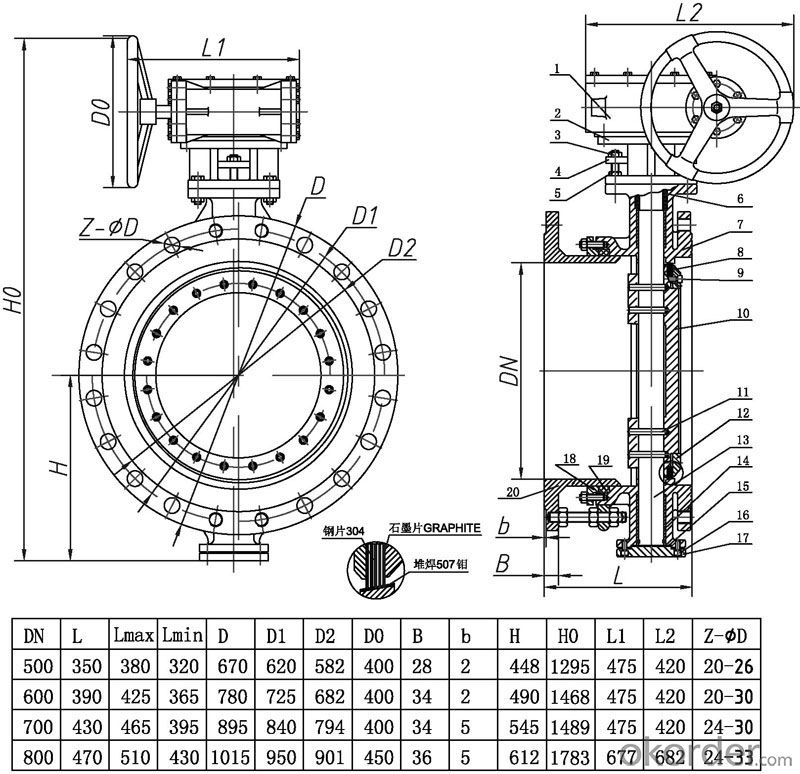

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: Transformer butterfly valve and pressure relief valve difference

- The butterfly valve is usually fitted with an oil immersed transformer between the tank and the radiator to control the flow of oil between the transformer tank and the heat sink. When large power transformers are delivered, the radiators are usually individually packed to reduce transport sizes. The butterfly valve is closed to prevent the outside air or water from entering the transformer tank. When the transformer is transported to the installation site, the radiator is installed on the butterfly valve one by one. When the radiator is installed, the butterfly valve can be opened so that the oil flow between the transformer, the oil tank and the radiator can be circulated, so as to play the role of heat dissipation.When the transformer is running, it is found that when the radiator has seepage, the butterfly valve can be closed to avoid further leakage of transformer oil, and a new radiator can be replaced.

- Q: What is the electric butterfly valve? Please, great God!

- Therefore, this butterfly valve is the best matching product of automatic fire sprinkler system. The structure characteristics and working principle: the top design electrical device the butterfly valve of the worm and the worm gear driving device, and with the stem straight connecting transmission. In the closed precision electromechanical device, opening mechanical instructions and imported electrical components and parts with rust proof valve.

- Q: How do i use a valve spring compressor. It looks like a c-clamp, so don't tell me how to use a smaller one, but the bigger one.Thanks

- save yourself the hassle and throw that thing away go back to your local auto parts store and buy the l shaped spring compresser should be about twenty dollars make sure vehicle is at tdc remove rocker arm bolt remove rocker arms going valve by valve do not mix them up must go in exactly the same order they came out now lightly tap the top of valve with a rubber mallet will help loosen retainers place compresser on rocker arm stud take r.a. nut and tighten till valve locks fall out or can be removed very small dont lose use compressed air to hold valves in place at tdc sorry that should have been first not hard but not easy to do rebuilt 350 motor from the guts out spent alot of money on spring compressers only to find out the simplest one worked the best the one like u got will give u hell i tried napas version craftsman all of them trust me use the L bar

- Q: I have 1993 Seville 4.9. I got a new EGR valve but it didn't help. I tested it with vacuum pump, it won't hold pressure at all, same with old one. Is that new EGR valve bad or just different type of EGR that vacuum pump won't work? Thanks!

- The first source, pages 20-22, lists all 9 basic types of EGR valves. Not all the types are vacuum operated, but check out #5 and #6 - they behave very differently from each other without a real live exhaust system connected to them.

- Q: What does the model D373H-16C of butterfly valve mean?

- For example: Z543H-16C bevel gear flange plate valve, nominal pressure 1.6MPa, the valve body is made of carbon steel valves valve name according to the mode of transmission, connection form, structure, lining material and type name. But here in the name of the content shall be omitted: (1) the connection form: "flange" (2. Structure: a): valve "rod" and "flexible" and "rigid" and "single gate"; B: "straight" stop valve and throttle valve; C: ball "floating" and "one-stop"; D: butterfly valve "vertical plate type"; E: the diaphragm valve "roof"; F: Cock "filler" and "one-stop"; G: check the "one-stop" and "single"; H: "safety valve is not closed. (3) the valve seat sealing surface material in the material name Said. I have just engaged in the valve industry, mainly to do www.ssfmsh traps, but also hope that we learn from each other and make progress together

- Q: Function of signal butterfly valve in fire sprinkler system

- The signal butterfly valve is generally installed in two parts: floor level, dry pipe, flow indicator front end, trunk pipe, wet alarm valve, front end.Floor level pipe installation is a function of the signal valve, when the floor spraying system needs repair, close the valve, open the end of the floor drain, emptying the water in the spray system, maintenance; two is the sprinkler system is not allowed inside water, when the butterfly is closed, will transmit a signal to the the fire alarm system, fire alarm system receives a monitoring signal (so called signal butterfly valve), fire sprinkler system that the floor is anhydrous state, fast repair.Wet alarm valve at the front of the signal butterfly valve with the main floor of the main role of the butterfly valve, first, maintenance, and two is the prompt sprinkler system, there is a signal butterfly valve closed, should be repaired as soon as possible.

- Q: What does the butterfly valve model d344h, d345h, d346h, d347h mean?

- According to the international standard of the letters and numbers apart to explain D344H D is a unit of butterfly valve, two unit 3 is driving mode: turbine, three unit 4 connection: flange connection, four unit 4 Structure: seal type linkage, five unit H sealing material: Cr13 stainless steelD345H compare yourself to the above. Unit 5 four is a sealed, single eccentric structureD346H four unit 6 is an unsealed center vertical plateD347H four unit 7 is unsealed double eccentricIn general, there is only one difference between them: the structural form is different!

- Q: Gate valve, butterfly valve and so on can do the valve so that?

- Do a lot of use valve and butterfly valve, pneumatic / hydraulic, or electric device, automatic control valve, adjust its switch angle, so as to achieve the purpose of regulation. For example, in the factory, in order to ensure the top pressure, then the pressure regulating valve, the valve is automatically adjusted by a butterfly valve! And there is also pressure regulator, pressure regulator valve series is used independently. Of course the more, is mainly used to adjust the flow!

- Q: Butterfly D371X5-16ZB1 what does each letter stand for?

- Daily valve pressThe regular model is out of step with you. I can only explain the regularD371X5-16ZB1D is butterfly valve3 is the turbine drive7 is the clamp connection1 is the display opening signX is a rubber seal16 is 16 kg pressureI don't know the other superfluous letters

- Q: When i waa replacing the valves in the las 4 valves , they dropped and i dont know how to make them go back up, and i dont want to take the engine out of the car, is there any tool to make the valve go back up or there is any way to do it?? People told me that i can crank it by and , but i dont know how to do it where do i have to do it, i need help please im begging for help!

- Engine dis-assembly is now required .

Send your message to us

Butterfly Valve DN700 BS5163 with Hand Wheel Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords