Hot Sell Butterfly Valve Concentric Rubber Wafer PTFE 360 Hard-Backed ISO 5211 Shaft Support

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

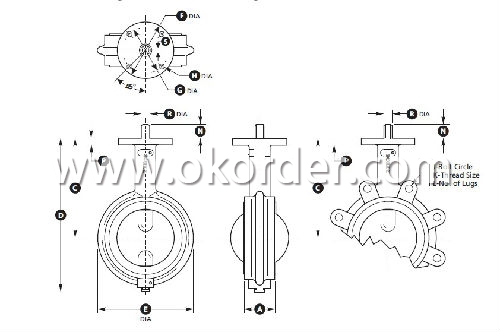

Description of Butterfly Valve

Concentric Butterfly Valve has a resilient rubber seat with a metal disc. This type of butterfly valves can be used for isolating or regulating flow.

Wafer, Lug or U type flanged body style fit between FF or RF flanges

PTFE bushing ensure the maximum shaft support and centralized alignment

360°polished disc assures positiveon-off

Hard-Backed Cartridge seat or Edge-Boot seat

The pin,spline or square connection are all available

Universal ISO 5211 mounting pad

Technical Data of Buttefly Valve

| Size | DN40-DN1200 |

| General Design | ISO 5752/BS 5155/API 609 |

| Mounting Pad | ISO 5211 |

| Face to Face | API 609/EN 558-1 20 series etc. |

| Flange Drilling | DIN 2501 PN10/16 |

| Inspection and Test | API 598 |

﹡For all available general design, face to face standard and flange drilling,please kindly contact CNBM directly.

Materials of Parts of Butterfly Valve

| Parts | Description | MaterialMaterial |

| 1 | Body | Cast Iron/Ductile Iron/WCB |

| 2 | Bushing | PTFE/Bronze |

| 3 | O-ring | EPDM/NBR |

| 4 | Shaft | Stainless Steel |

| 5 | Disc | Stainless Steel/Al-Bronze/Ductile Iron |

| 6 | Seat | EPDM/NBR/VITON/PTFE |

| 7 | Pin | Stainless Steel |

﹡For other material request,please kindly contact CNBM directly.

- Q: How warm is the PTFE butterfly valve?

- Ordinary PTFE clip butterfly valve normal temperature tolerance of about 120 degrees, instantly to about 150 degrees

- Q: Function of signal butterfly valve in fire sprinkler system

- The signal butterfly valve is connected with the fire alarm system to monitor the switch status of the valve, thus effectively preventing misoperation

- Q: How do hydraulic butterfly valves work?

- Butterfly valve hydraulic drive device working principle1. manual operationWhen the hydraulic system suddenly fails, the valve can not move when the butterfly plate at any stop. Then, shaking the manual device, the guide block guide block in front of the manual shaft together with the driving shaft end, the cogging and drive shaft spline manual corresponding to the slot. Then, by dialing the driving device, the dial is shifted to the left end, and the transmission spline is connected with the manual shaft by a gear sleeve (the driving device is provided with a limit for preventing the tooth sleeve from jumping up), and the crank is disengaged from the hydraulic cylinder to disengage the hydraulic cylinder. Then turn the manual device and use the manual device to realize the disc movement.2. hydraulic operationWhen the hydraulic system returns to normal operation, the actuating device needs to be operated by hand. First, adjust the hydraulic cylinder to its initial state (0 digits) or at any position. Then manually adjust the opening of the disc to the position corresponding to the cylinder stroke (by observing whether the mark on the gear sleeve is in accordance with the mark on the crank, and judge the position of the disc and the cylinder). Then pull the gear sleeve and engage the spline on the crank by poking the driving device. Then fix the shift to prevent jumping. At this point, start the hydraulic system to restore fluid flow.

- Q: Gate valve, butterfly valve and so on can do the valve so that?

- Yes, but the accuracy of the adjustment is not high. Just about. To adjust the flow, please use flow control valve.

- Q: For example, the arrow above is from left to right, and the direction of my current is from right to left. Is that ok? I have a diameter of 700 of the hard seal butterfly valve is so installed, but it will leak water, it will not leak, very serious

- The direction of the arrow on the valve body refers to the direction of the medium.Also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control the flow of air, water, steam steam, all kinds of corrosive medium, mud, oil, metals and radioactive liquid media and other types of fluid. On the pipeline, mainly from cutting and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation.

- Q: Butterfly valve, two-way pressure and one-way pressure what is the difference?

- One way sealing butterfly valve is the front of the butterfly valve. When it closes, it must face the direction of the medium. The medium flows only in one direction, and the arrow on the valve body indicates the direction of the flow direction of the medium. Attention should be paid to the flow direction of the medium during installation. Two way butterfly valve is butterfly plate can face or back to the media flow direction, installation without attention to medium flow direction, in the valve body also does not indicate the direction of the medium flow arrow. Two way sealing butterfly valve stem force is greater than one-way butterfly valve stem. Design, the same diameter, pressure butterfly valve, two-way sealing butterfly valve rod diameter than one-way sealing butterfly valve stem diameter.

- Q: what are the step i need to do so i can change the valve seals my truck has been smoky.,,, any websites i want todo it myself... 1989 chevy silverado 2500 350 engine 5.7L

- If it only puffs blue smoke when you start it and then burns off after a second then its the valve stem seals that need to be replaced which is common on 350 and 305 engine prior to 1990 and have over 150,000 miles or so. The Chilton repair manual explains the procedure on how to replace these.Now if it smokes all the time then it could be caused by worn out rings on your pistons .

- Q: DN80 flange butterfly valve, DN80 flange butterfly valve DN80, flange butterfly valve DN80 what is the difference?

- Of course there are differences, the general market sales of the DN80 are many flange plate copper rod butterfly valve, quality can not reach the national standard, to use copper rod copper butterfly valve quality is king.

- Q: How to control the single acting pneumatic butterfly valve?

- There are single acting pneumatic head, we must pay attention to often open or normally closed, we must pay attention to.

- Q: I did a compression check on my 350 chevy. I have low compression of 175psi on one cylinder.The other seven cylinders range from 195psi to 205psi Could the valves be too tight on the cylinder with 175 psi compression?

- unless they have been tampered with that wouldn't be it,they usually wont tighten up on their own,i would suspect maybe a valve with a slight burn place on it that's causing that to happen or a ring causing you to loose that much compression,try adding a small amount of oil in the cylinder and then do the compression test again,that will tell you if its a ring or a valve,that's a big loss of compression ,and when you see that much of drop its usually a burnt valve.good luck.

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 2006 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;North America;Asia;Africa |

| Company Certifications | ISO9001:2008 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 20-50 |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 8,350 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hot Sell Butterfly Valve Concentric Rubber Wafer PTFE 360 Hard-Backed ISO 5211 Shaft Support

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords