Butterfly Valve DN550 Made in China Britain Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

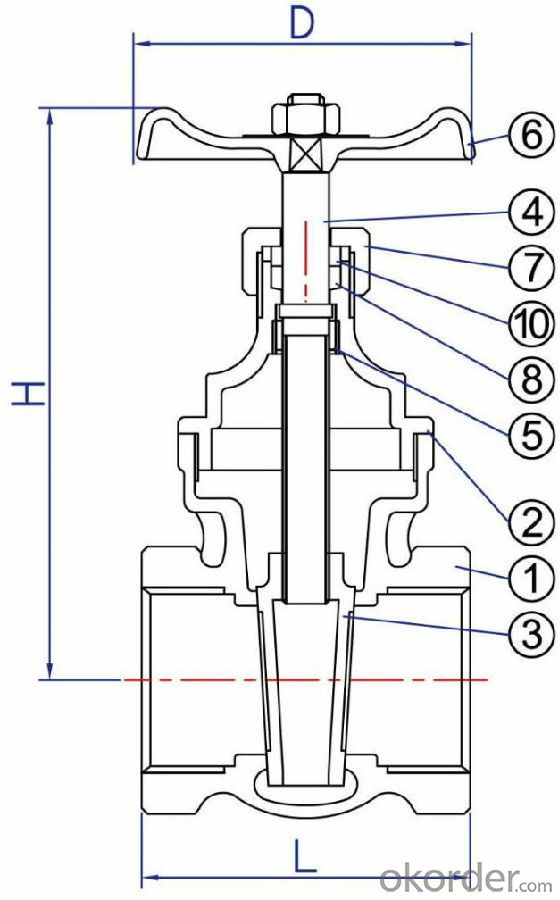

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: What does "D341X-16Q" mean?What do D341-16Q letters and numbers mean for butterfly valves?

- D - valve type code: Butterfly valve;3 - valve drive mode code: worm gear;4 - valve connection form code: flange;1 - valve structure type code: vertical plate type;X - seat sealing surface or lining material code: rubber;16 - nominal pressure value: PN1.6MPa;Q - body material code: QT400 - 15.

- Q: The difference between butterfly valve d71x_10s and d341s-10

- Before distinguishing between the two, you must first read the identification of the valve type:D stands for butterfly valves,3 means that the worm gear is connected and the drive does not indicate the handle7 and 4 indicate pipe to clamp connection, pipe flange connection, respectively1 means single eccentric, that is, the stem is not in the center of the butterfly plateThe former S indicates the material name of the valve body - plastic, X means sealing and the lining material is rubberThe latter S indicates the sealing lining material code ---- plastic, and the valve body is cast iron.10 means stress.

- Q: How do i use a valve spring compressor. It looks like a c-clamp, so don't tell me how to use a smaller one, but the bigger one.Thanks

- the forked end of it will go over the spring part and the solid will work on the valve ,you can only use this one if the head is off though,the smaller ones work good if the head is still on the car,the c-clamps style though is the best one to use its safer and wont allow the springs to fly off,good luck.

- Q: What does the model D373H-16C of butterfly valve mean?

- For example: Z543H-16C bevel gear flange plate valve, nominal pressure 1.6MPa, the valve body is made of carbon steel valves valve name according to the mode of transmission, connection form, structure, lining material and type name. But here in the name of the content shall be omitted: (1) the connection form: "flange" (2. Structure: a): valve "rod" and "flexible" and "rigid" and "single gate"; B: "straight" stop valve and throttle valve; C: ball "floating" and "one-stop"; D: butterfly valve "vertical plate type"; E: the diaphragm valve "roof"; F: Cock "filler" and "one-stop"; G: check the "one-stop" and "single"; H: "safety valve is not closed. (3) the valve seat sealing surface material in the material name Said. I have just engaged in the valve industry, mainly to do www.ssfmsh traps, but also hope that we learn from each other and make progress together

- Q: What is the effect of nylon coating on butterfly valve plate? Thank you

- Mainly media will not be contaminated by rust on the body, you should say that the central soft sealing butterfly valve, the central valve is generally cast steel or cast iron material, so useNylon coatingLining up. There are soft seals, sealing performance is relatively high

- Q: What do you mean by manual butterfly valve DN100 D341X-10?

- DN100 refers to the inside diameter of the butterfly valveD stands for butterfly valves3 represents the turbine drive4 represents the flange connectionThe 1 represents straight throughX is the representative of the Dengqen rubber seal10 represents the pressure of 1.0Mpa (10 kg)Butterfly valve (English: butterfly valve) refers to the closure of parts (valve or butterfly plate) for the disk, around the valve shaft to achieve rotation and closure of a valve, the main cut off on the pipe and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation. Butterfly valve is fully open to fully closed is usually less than 90 degrees, butterfly and butterfly stroke itself has no self-locking capability, in order to position the disc to install the valve stem on the worm gear. Using worm gear reducer, not only can the butterfly plate have self-locking ability, so that the butterfly board stops at any position, but also can improve the operation performance of the valve.

- Q: What are the functions and uses of butterfly valves?

- Butterfly valve (English: butterfly valve) refers to the closure of parts (valve or butterfly plate) for the disk, around the valve shaft to achieve rotation and closing of a valve, the main cut off on the pipe and throttling role. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation.

- Q: Which is expensive, butterfly valve?

- Gate valve and butterfly valve can not simply take the price there to compare, look at the actual design requirements of the project. General small caliber are selected by the valve, because of better sealing performance, service life is long, the maximum diameter of valve is usually choose to use the butterfly valve to the pipeline DN800800 above, because the valve is cheap, the price is only half of the large diameter valve. Also some pipes from the use of quality point of view, will choose the gate valve. How to use it, please mark the map

- Q: Hi guys, i asked a question before pertaining to the amount of cylinders and asking if it meant V4 or V6 or whatever.I actually meant to say VALVES, not cylinders. IS there a direct correlation between VALVES and Clyinders..Eg, My car, which is a 2001 Neon LE states right on the engine block quot;16 VALVEquot; in bright letters. I am sure this is a 4 cylinder engine. I haven't had a car that broadcasted the number of VALVES before. Another car I had broadcast that is was a 3.3 Liter V6 right on the engine.Is there a mathematical relationship between VALVES and cylinders, or would my car be braodcasting 16 VALVES, because a 4 cylinder doesn't typically HAVE 16 valves, or what is the story??Recently, I was looking at an altima, and it said 24 valves. Can you tell just by the number of valves if it is a 4 cylinder or 6 cylinder or whatever??Thanks.

- All engines require one intake and one exhaust valve per cylinder. Period. That said, some engines are equipped with two intake and two exhaust valves per cylinder. So a four cylinder engine will be labeled as either an 8 valve or a 16 valve engine. And so forth for a six cylinder or an eight cylinder engine. In the motorcycle world, there are the rare engines equipped with either three valves per cylinder or five valves per cylinder. So if a manufacturer is advertising the number of valves per cylinder right on the car or engine, you can bet that engine is equipped with four valves per cylinder. 4 valves per cylinder is more expensive to manufacture than a 2 valve engine, but there is better performance with 4 valves per cylinder. To the last part of your question, 24 valves equates to a 6 cylinder engine. 24/4 = 6 (cylinders). I know of no engines with 6 valves per cylinder. Also Altimas are not available with 8 cylinder engines. Good Luck

- Q: Hey YA! I am looking at getting an 01 Honda Prelude this month and valve adjustment keeps coming up when people discuss this car and other cars as well. What is this? Does it cost a lot to do, and is it important? Thank you!

- An import shop can probably do this in two hours and cost should be in the general range of $200-300 I'd estimate. There is a camshaft that acts on the valves, and there is a predetermined amount of play or slop in the system that is within specs. As the valve seat wears, the valve gets pulled further into the head, and this lessens the play as it wears. If it gets too tight and fails to have any play, the valve won't be held tight against the seal and it will leak, lose power and possibly burn the valve. So yea, get it set. Also may want to factor in timing belt cost and ask about that and water pump as those aer replaced together.

Send your message to us

Butterfly Valve DN550 Made in China Britain Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches