Butterfly Valve DN500 BS5163 Made in China Britain Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

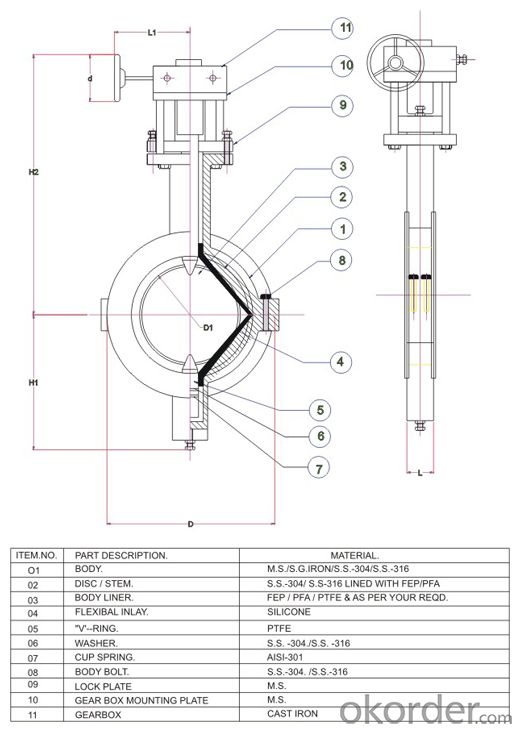

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

1)Size: DN40-DN1400

2)Material:body-CI/DI/WCB/SS

disc:DI/CF8/CF8M/C95400

3)Professional Maufacturer for more than 10 years

PRESENTATION:

1) Sizes:

DN40mm-DN1400mm

2) Materials:

a) Body: CI(cast iron ,GG25 )/ DI (ductile iron ,GGG40)

b) Disc: DI / CF8 / CF8M / C95400

c) Seat: EPDM / NBR / TEFLON / VITON

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: Does the wet alarm valve group need to install the signal butterfly valve?

- two is the sprinkler system is not allowed inside water, when the butterfly is closed, will transmit a signal to the the fire alarm system, fire alarm system receives a monitoring signal (so called signal butterfly valve), fire sprinkler system that the floor is anhydrous state, fast repair.

- Q: i have a slightly small mitral valve leak in my heart. my cardiologist say nothing to worry about, but i am not sure. can some one explain if it would eventually lead to some complications?

- Dear Madam, I am a cardiologist sending this article for you. Hope it helps you. Mitral valve prolapse, sometimes called MVP, is a common heart valve disorder. The mitral valve is between the left atrium and the left ventricle of the heart. It has two leaflets (flaps) that control the blood flow. MVP occurs when one or both of the leaflets are enlarged or have extra tissue. MVP is usually harmless. However, major complications can occur, including a blood clot in the brain and an infection called infective endocarditis involving the mitral valve as well as other valves. MVP appears twice as often in women as in men. It is most commonly a hereditary disorder. Some people with MVP have no symptoms. However, most patients experience a rapid or irregular heartbeat, shortness of breath, light-headedness, and chronic fatigue. Many patients also suffer from migraines, eating and sleeping disorders, an overactive or inflamed thyroid gland, diarrhea, and cold hands and feet. Emotional stress often magnifies the symptoms. Doctors generally prescribe regular exams and aerobic exercise for people who have MVP. Patients also are advised to restrict their intake or use of high-carbohydrate foods, caffeine, and decongestants. Some patients may need beta-blockers and specific antiarrhythmic medication. More severe cases may require surgery to repair or replace the valve or to insert an electronic regulator, such as a pacemaker or defibrillator.

- Q: Why anti condensation of aluminum alloy anti condensation butterfly valve?

- High performance materials have a lot of outstanding advantages: such as low water absorption, corrosion resistance, insulation, cold insulation performance, etc., is 4 times the ordinary material butterfly valve.Anti condensation butterfly valve body adopts ultra light aluminum alloy valve body, its weight is only 1/3 of the traditional butterfly valve, the torque is small, the use and installation is convenient, and the corrosion is avoided.

- Q: What's the difference between a clip on handle butterfly valve and a turbo butterfly valve? Where are they used?

- Depending on the size of the valve and the opening and closing torque, the transmission mode is different (handle or turbine).

- Q: Butterfly valve model D344H and D343 difference

- [2]: butterfly valve also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control the air water, steam, and all kinds of corrosive media, mud, oil, metals and radioactive liquid media and other types of fluid flow. On the pipeline, mainly from cutting and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation.The answer is recommended by Gu Fengxiang, a member of the science education category

- Q: How can one - way sealed butterfly valves and two-way sealed butterfly valves be distinguished?

- Two way hard sealing butterfly valve:Two way butterfly valve on the valve body usually does not indicate the direction of the media arrow sign, in the design of two-way sealing butterfly valve stem force is greater than one-way butterfly valve stem. The same diameter, pressure butterfly valve, two-way sealing butterfly valve rod diameter than one-way sealing butterfly valve stem diameter. At the time of installation, the butterfly plate can face or back the direction of the medium, without considering the flow direction of the medium.

- Q: How big is the butterfly valve with a diameter of 80?

- Generally speaking, especially small caliber, the butterfly valve will not use the variable diameter. Therefore, the butterfly valve DN and pound class selection, according to the field pipeline flange DN and pound level.So, in a strict sense, the caliber of the butterfly valve and the diameter of the pipe have not much relationship.Specific to your pipe diameter, there are questions: 80 diameter refers to the outer diameter or inside diameter? Yes, there is no flange on the site. Do you need a pair of flanges to be supplied?

- Q: Import electric butterfly valve which brand is more reliable?

- Recommend Sichuan Ding Heng petroleum machinery company sales agent SPM butterfly valve and FMC butterfly valve, we are partners for many years, have been working together are very happy.

- Q: Butterfly D371X5-16ZB1 what does each letter stand for?

- Daily valve pressThe regular model is out of step with you. I can only explain the regularD371X5-16ZB1D is butterfly valve3 is the turbine drive7 is the clamp connection1 is the display opening signX is a rubber seal16 is 16 kg pressureI don't know the other superfluous letters

- Q: What's the meaning of butterfly valve d371po?

- According to the provisions of the JB/T 308-2004 valve type programming method:D== butterfly valve3== transmission: worm gear7== connection mode: clip type1== structure: midlinePo== sealing surface material: lining PoPo== propylene oxide (PO)

Send your message to us

Butterfly Valve DN500 BS5163 Made in China Britain Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches