Brushed Aluminum Adhesive Sheets - Grey Color Back Coated Aluminum Sheet Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of PVDF AluminumCoil:

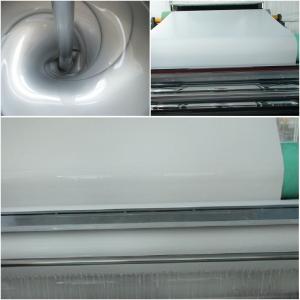

1. Adopting precision rollingcoating technology, our PE coated coil can ensure excellent adhesive withoutcoating omission.

2. For the PVDF coatedaluminum sheet we produced, there are various colors for your choice.

3. Using infrared heatingtechnology to protect environment from pollution.

4. Our coated aluminum coilhas four-roller coating line, uniform coating thickness and good features.

Raw Material of the PVDFCoated Aluminum Coil:

1. Aluminum Coil: highstrength aluminum with alloy of AA1100 (aluminum alloy is available withAA3003, AA3005, AA5005 according to customer)

2. Surface Paint: PE, PVDF andspecial paints.

Specification of the PVDFCoated Aluminum Coil:

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm,505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

Performance and usage

PVDF coated aluminum coils are specially processedthrough the technics of roller coating and baking with precise paints fromBECKER INDUSTRIAL COATINGS in

Performance of the coating

Aluminum Thickness | Coating Thickness | MEK | T Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥25μm | ≥100 Times | ≤2T | 50kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.28mm | ≥25μm | ≥100 Times | ≤2T | 20kg•cm | 0 Grade | ≥HB | no change within 2 hours |

Color of Card

Our PVDF coated aluminum coil is made offluorine carbon resin, pigment, ester solvent after high temperature roastingand baking. The paint of this PVDF coated aluminum coils are solidified to dryfilm with super weather resistance. PVDF coating also can be classified astraditional PVDF and nanometer PVDF coating.

A. Traditional PVDF Coating, with KYNAR500 PVDF and two or three times forcoating and baking, has good properties of anti-acid, anti-alkali and isdurable in atrocious weather and environment, keeping 15 years no unwontedfading. In view of these facts, we recommend this PVDF coated aluminum coilsare applied for external wall cladding.

B. Nanometer PVDF Coating, which different with traditional PVDF, is the clearcoating. It contains nanometer element, which can protect panel from pollution,because nanometer has self-cleaning effect, it is easy to get rid of dust andpollution by raining or water.

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, soit is suggested all panels are placed in one order for same project. And keepsame direction as arrow on protective film when installing to avoid any colordifference by vision.

PE Aluminum Coating Coils for ACP

Featuresof PE Aluminum Sheet:

1.Adopting precision rolling coating technology, our PVDF and PE coated coil canensure excellent adhesive without coating omission.

2. For thePE coated aluminum coil we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wallpanels, advertisement boards, counters, home appliances, decoration in and outof autos and boats.

Performance of thecoating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: Can aluminum sheet withstand heavy loads?

- Yes, aluminum sheet can withstand heavy loads. Aluminum is known for its high strength-to-weight ratio, making it an excellent choice for applications that require durability and load-bearing capabilities. Aluminum sheets are commonly used in industries such as aerospace, automotive, construction, and marine, where heavy loads are involved. Additionally, aluminum's inherent corrosion resistance further enhances its ability to withstand heavy loads over extended periods. However, it is important to consider the specific grade and thickness of the aluminum sheet, as different alloys and thicknesses have varying load capacities.

- Q: Is it possible to use aluminum sheets as a material for interior walls?

- <p>Yes, aluminum sheets can be used for interior walls. They are known for their durability, resistance to corrosion, and ease of maintenance. Aluminum sheets can also be painted or finished in various ways to match different interior design styles. They are lightweight, which makes them easy to install, and they provide good thermal insulation. However, it's important to consider the acoustic properties and the need for proper insulation to prevent condensation, especially in colder climates.</p>

- Q: I need to know what composite bats do and how (or if) they are better than aluminum bats.

- This Site Might Help You. RE: What is the difference between composite bats and aluminum bats? I need to know what composite bats do and how (or if) they are better than aluminum bats.

- Q: My understanding of the periodic table, the transitional metals all rust because the S shells are higher energy then the D shells. So all transitional metals have 2 valence electrons. (Roughly...some electrons like to move around and give different apparent charges.) So why does aluminum corrode if it doesn't have a 2+ charge?

- 'Rusting' commonly refers to the corrosion (oxidation) of iron so when talking about other metals, it is better to use the term 'corrosion' or 'oxidation'. Aluminum can corrode and the fact that it has a general oxidation number of +3 doesn't really matter. Many elements which have a charge that is different from +2 can oxidize. Alkali metals for instance (which have a charge of +1) can oxidize. Lithium can form lithium oxide (Li2O), sodium can form sodium oxide (Na2O) and so on. However, aluminum is known to be quite resistant to corrosion (oxidation) because it spontaneously forms a thin (solid) oxide layer at it's surface protecting it from further oxidation whereas iron, for an example, will easily lose that thin layer (it ''peels off easily'') exposing more iron to corrosion. So since Al has a +3 charge and O has a -2 charge, you'll need 2 atoms of Al and 3 atoms of O to make an electrically neutral compound. 2 atoms of Al = +6 charge 3 atoms of O = -6 charge Hence Al2O3 which is aluminum oxide. I hope it helps.

- Q: How much is a square inch of a millimeter aluminum plate?

- Weight 2.68 kg / square meterThis explanation is not difficult to explain the same square metre. Why is the weight different?

- Q: How do aluminum sheets compare to steel sheets in terms of weight?

- Aluminum sheets are significantly lighter than steel sheets, as aluminum has a lower density compared to steel.

- Q: What is the typical sheet size tolerance for aluminum sheets?

- The typical sheet size tolerance for aluminum sheets is typically around +/- 0.005 to 0.010 inches.

- Q: What is the standard thickness of aluminum sheets used for exterior building applications?

- <p>The typical thickness of aluminum sheets used for building exteriors ranges from 0.7mm to 1.2mm. This range is suitable for applications such as facades, cladding, and roofing. The specific thickness can vary depending on the structural requirements, wind loads, and the overall design of the building. Thicker sheets may be used for more robust structures or in areas with higher wind pressures, while thinner sheets can be used for lighter applications or when a more aesthetically pleasing finish is desired.</p>

- Q: This question asks about the structural integrity and suitability of aluminum sheets for use in the construction of high-rise buildings.

- <p>Aluminum sheets are not typically used as the primary structural material in high-rise buildings due to their lower strength compared to steel and concrete. However, aluminum is known for its high strength-to-weight ratio, making it suitable for non-structural applications such as facades, window frames, and roofing. In high-rise construction, aluminum can be used in combination with other materials to provide a lightweight and aesthetically pleasing exterior while maintaining structural integrity with stronger materials like steel and concrete.</p>

- Q: How do aluminum sheets compare to copper sheets in terms of conductivity?

- Aluminum sheets have lower conductivity compared to copper sheets.

Send your message to us

Brushed Aluminum Adhesive Sheets - Grey Color Back Coated Aluminum Sheet Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords