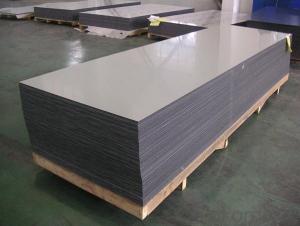

Brushed Aluminium composite panel ACP composite panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Brushed Aluminium composite panel ACP composite panel

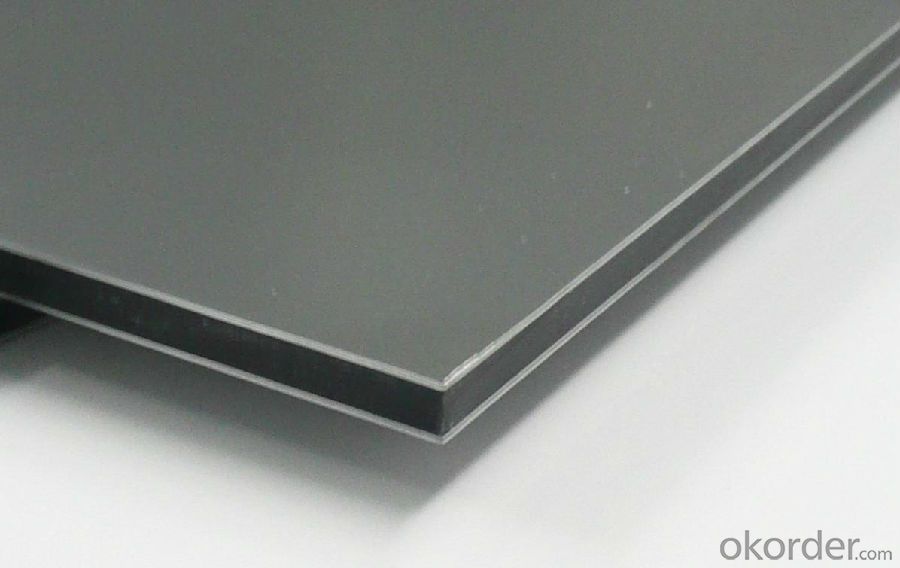

1. Standard:

according to GB/T 17748-1999 standard

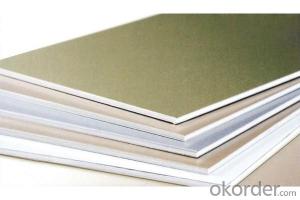

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

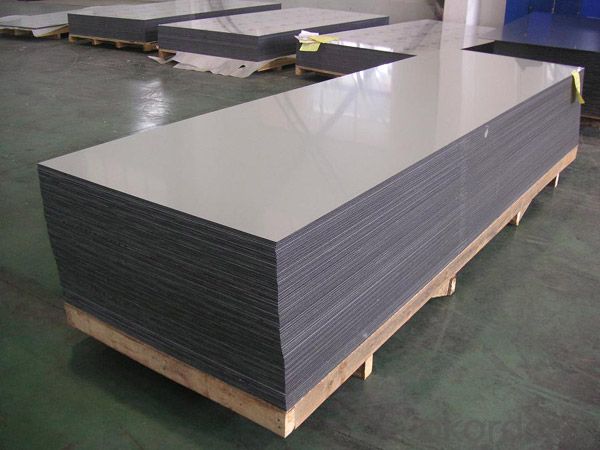

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

7) Industrial materials, materials for vehicles and boats

Production Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Coating line | WANGUAN | 2 | 4.5 | Acceptable |

| Aluminum plastic composite line | FB1600 | 4 | 3.5 | Acceptable |

| Embossing line | No information | 1 | 1.0 | Acceptable |

Testing Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Bending machine | No information | 1 | 8.0 | Acceptable |

| Visual comparison of the colour device | MSBS-1 | 1 | 5.0 | Acceptable |

| Drying oven | PULUO | 1 | 5.0 | Acceptable |

- Q: How to adjust the length of the aluminum plate

- According to the current production situation, many manufacturers already have the width of the custom, the standard width of 1220 mm, of course, can also provide 1100 mm and 1570 mm width, as other widths such as 1000 mm or 1600 mm, can be achieved.

- Q: Can aluminum plate prevent radiation?

- Probably only the lead plate to radiation, did not hear that there are other materials have this performance.

- Q: How to paste the wallpaper on the aluminum plate

- No problem, sticky bar but to choose a good glue, the aluminum plate will not be damaged

- Q: 3d board and aluminum plate prices? What kind of price?

- Three-dimensional board, including polymer composite board, aluminum plate, color plate and other molding materials, in general, polymer composite board, aluminum plate are in the price is higher than the aluminum-plastic plate.

- Q: What are the hazards of aluminum-plastic panels?

- Mercury (Hg) affects the nerves, appetites and the brain in charge of the central nervous system, the immune system

- Q: How to clean and keep the aluminum plate

- The surface of the aluminum composite panel requires regular and regular cleaning and maintenance. This cleaning is not just to keep the walls of the building clean and beautiful, but to regularly spread the paint on the surface of the paint The removal of the stain to ensure the long-term quality of the paint. The cycle of cleaning is mainly determined by the environmental conditions of the project location and the extent of the actual contamination of the board. Our proposal is that the building wall should be cleaned at least once a year. The interior wall should be cleaned according to the actual degree of corruption The

- Q: Are there any differences between aluminum slabs and aluminum panels?

- Nature is not the same, Encyclopedia check more clearly

- Q: Is the aluminum-plastic board protective film toxic?

- Aluminum plastic plate life is short, good antioxidant capacity, are generally used in the door or store decoration, home improvement generally do not use aluminum-plastic plate. If you take into account the environmental protection, it is recommended to use your favorite panel and then brush on the favorite color.

- Q: 30-storey residential building roof concrete flower frame decorated with aluminum-plastic plate, please apply to apply lightning belt can not do? Using aluminum-plastic plate grounding

- But the conductivity can not have a metal component can also be depending on whether the material connection insulation.

- Q: How much is the bigger the better

- Which relates to one of the raw materials of aluminum-plastic plate aluminum foil or aluminum skin, the thickness of the commonly used silk to express. Such as 0.10 mm, it is called 10 silk, 0.50 mm thick aluminum is called 50 silk.

Send your message to us

Brushed Aluminium composite panel ACP composite panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords