PE coating Aluminium composite panel ACP Aluminium

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

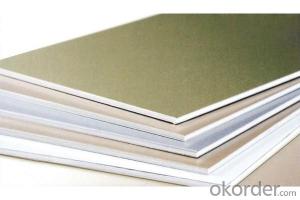

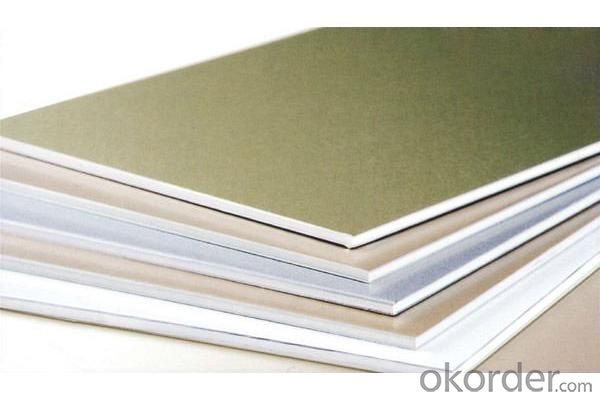

PE coating Aluminium composite panel ACP Aluminium

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

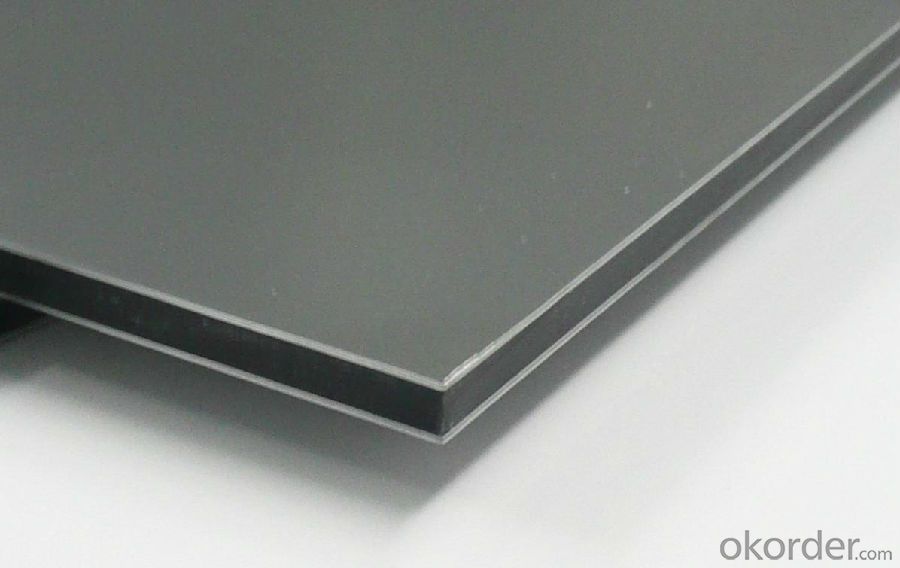

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

7) Industrial materials, materials for vehicles and boats

Production Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Coating line | WANGUAN | 2 | 4.5 | Acceptable |

| Aluminum plastic composite line | FB1600 | 4 | 3.5 | Acceptable |

| Embossing line | No information | 1 | 1.0 | Acceptable |

Testing Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Bending machine | No information | 1 | 8.0 | Acceptable |

| Visual comparison of the colour device | MSBS-1 | 1 | 5.0 | Acceptable |

| Drying oven | PULUO | 1 | 5.0 | Acceptable |

- Q: What is the difference between aluminum-plastic and plastic?

- Is a product of two different names only.

- Q: Aluminum plate casting machine pit how to get out of aluminum

- 1000 series 1050 aluminum plate. Food, chemical and brewing industry with extrusion coil, all kinds of hoses, smoke pollen 1060 aluminum plate. Requirements of corrosion resistance and formability are high occasions, but the strength is not high, chemical equipment is its Typical use 1100 aluminum plate. For processing need to have good formability and high corrosion resistance but does not require high strength parts parts

- Q: Is the aluminum-plastic plate plastic? What is the difference between the two? What are their uses?

- They belong to the same kind of decorative material. Its advantages are: surface smooth, uniform color, long life, simple construction and so on. (But the price is more expensive). Generally used for building facades, store decoration (should use better quality brand) can also be used for home interior decoration.

- Q: What are you doing? Why is it so familiar with the knowledge of aluminum-plastic panels? Do you think there is now a market for getting aluminum-plastic composite panels? Thank you!

- Many peers say that aluminum-plastic plate is sunset products, only five years of development. I now feel that the aluminum-plastic plate industry is not very good to do, to seek new industries

- Q: Today, just started to do LED electronic light box, with aluminum-plastic plate openings, plug lights, even lights, street controller, that is done well. Ready to power, check with multimeter, find! shock! The Aluminum-plastic plate side is aluminum foil, conductive! The The 1 how to do? The The LED electronic light box, not using aluminum plate to do it? The

- There is a problem with your production method. Or learn it well

- Q: Heroes are good, I would like to know that aluminum-plastic plate is one side of the aluminum, one side of the kind of material is plastic? About three or four millimeters thick! Is it done with this board?

- One side is aluminum foil side is pvc or plastic

- Q: On the report of the project price per square meter engineering requirements is to use 50 * 5 angle iron keel with 4mmA grade aluminum-plastic plate dry hanging

- Skeleton production and installation of aluminum-plastic composite board for the plastic layer are pressed up and down a layer of aluminum sheet, and then in the aluminum plate surface by roller coated with fluorinated vinyl resin, made by baking, aluminum plate using mechanical milling, And leave a 0.3mm thick core material, so as not to hurt the inner surface of the panel. After the cut, fold, strengthen the ribs of the security system. Install the finished parts after installation

- Q: To ask you to install the acrylic LED aluminum-plastic edge light-emitting words with self-tapping to install the aluminum plate, then the side of the font cone hole can cone it? Fear the cone to the board above the board?

- Can drill, do not drill too much inside. This kind of word is usually coated with foam double-sided adhesive plus glass. Do not have a screw

- Q: The minimum thickness of single-layer aluminum and aluminum-plastic composite panels for curtain walls

- Single-layer aluminum thickness of not less than 0.2mm

- Q: What is the difference between aluminum and aluminum curtain wall aluminum veneer? That cost is high!

- Composite aluminum is also known as aluminum composite panels,

Send your message to us

PE coating Aluminium composite panel ACP Aluminium

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords