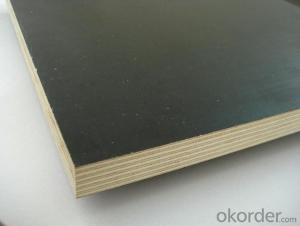

Brown Film Faced Plywood, Concrete Formwork Shuttering Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

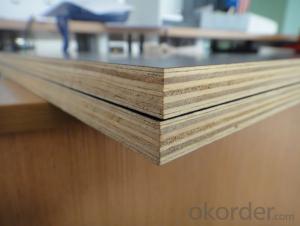

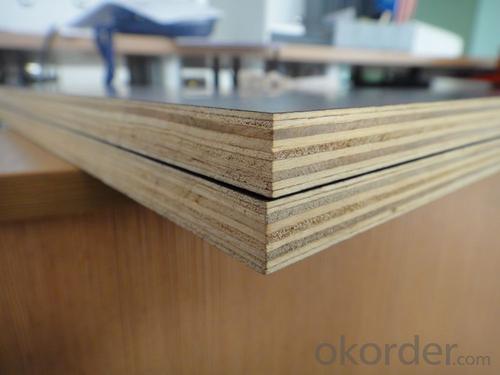

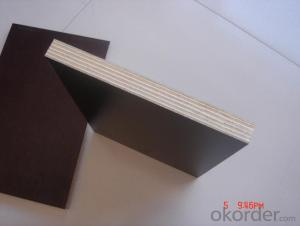

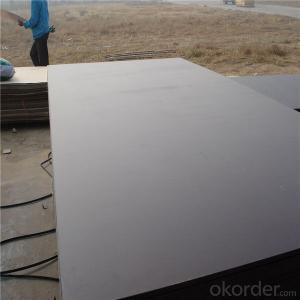

Item Name:Film Faced Plywood/Shuttering Plywood

Size:1220x1440mm,1250x2500mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,other thickness as requested

Description

Item | Film Faced Plywood | |

Face/back |

black film or brown film,logo available | |

Core Material | poplar,hardwood,combi,finger jointg board,etc. | |

Size(mm) | 1220x2440, 1200x2400, 1250x2500, 1830x915,610x2440,etc. | |

Thickness | 9mm 12mm 15mm 18mm 21mm | |

Grade | One time hot press, two times hot press,three times hot press | |

Length(width) tolerance | 1mm | |

Thickness tolerance | +/-0.5mm or +-1mm | |

Glue | WBP(phenolic), MR, WBP MELAMINE | |

Mositure content | 8%-16% | |

Main market | Saudi Arabia,South America,Africa,Europe, India,Southeast Asia,South Korea,Thailand,etc | |

packing | Inside:pallet is wrapped with 0.2mm plastic bags; outside:pallets are covered with caton paper or plywood ,and then PVC/steel tape for strength | |

Loading quantity | 20GP | 8pallets/20M3 |

40GP | 16pallets/42M3 | |

40HQ | 18pallets/55M3 | |

Usage | Widely used for concrete formwork,shuttering work,construction,truck flooring,etc. | |

Minimum Order | 1*20GP | |

Payment | T/T or L/C at sight | |

Delivery Time |

10-30 days according to order quantity | |

Features

1) Good Raw Materials and High quality

2) More repeated using times

3) Good packing and fast shipment

4) Delivery the right products according to different level of requirement

5) High performance/price ratio

FAQ

A. Quality :

With the skilled worker ,mature technology and ten years experience ,all our plywood are steady quality .

B. Price:

Due to the skilled worker ,mature technology and an experienced operating system , we can

quote you competitive price , so that you will have the price advantage to capture your market.

C.Service:

7*24hours , if any need, you can email or call us,we will do our best to meet your demand

D.

Export experience:

Over ten years experience for exporting ,We are much familiar with

the export operation .

Packaging:

The pallet lined with 0.2mm plastic bag, the outside is coverd by 2.3mm commercial plywood, and then with steel tape for strength.

Shipping:

All the goods will be delivery within 20 days after we get the deposit or L/C

Products Photos

- Q: What are the allowable quantity differences in printed packaging materials?

- Light, bright colors for screen printing in India due to the leakage characteristics, so it can use a variety of ink and paint, not only can use the slurry, binder and pigment can also use coarse pigment. In addition, the method of screen printing ink preparation is simple, for example, it can be directly transferred into the light pigment ink, which is another main feature of screen printing. Screen printing products have strong light and have great advantages. Practice shows that the black ink coated paper embossing by measuring the scope of the use of the maximum density value, compared to 1.4, 1.6 and 1.8 letterpress, gravure, screen printing of the maximum density deviation range of 2 can be, therefore, the light screen printing products than other types of printing products lightfastness stronger resistance that is more suitable for outdoor advertising, signs of purpose.

- Q: What's the printing process for PC material? Is the print content on PC or other surfaces?

- As a screen printing material, semi automatic screen printing machine for printing or anti India, in particular circumstances, is usually anti India, India will.

- Q: Carton printing process and materials

- Single-sided corrugated production line adopts plastic gravure printing process composite paper carton packaging, paper printing also need to be completed if the light coating film, and large volume production, can be printed on the paper, and the way for gravure printing gravure printing on plastic film, and with white plastic film and paper and then the first printed composite, and then complete the box according to the conventional carton forming process.The process is characterized by:(1) the cost of making cartons is low. When the production batch is large, the printing cost and the material cost of the facial tissue can be greatly reduced by the process. Because the paper does not need to be printed, the uncoated white board paper can be used so as to greatly reduce the cost of the facial tissue.(2) beautifully printed. Because the plastic gravure printing is adopted, the printing effect can be compared with the offset printing effect. The process requires special attention. In the process of printing, it is necessary to take full account of the plastic film size changes and deformation; otherwise, the carton paper will be inconsistent with the lower paperboard.

- Q: What are the materials used in screen printing?

- Divided into printed screen and printed material, screen according to different processes are divided into water-based and solvent based, printed material according to different substrate is divided into ink and ink

Send your message to us

Brown Film Faced Plywood, Concrete Formwork Shuttering Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords