3M Shipping Packaging Tape - BOPP Tape Water Based Acrylic Clear Transparent

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Bopp Tape is of Bopp film as the carrier, coating with water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Bopp Tape: widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

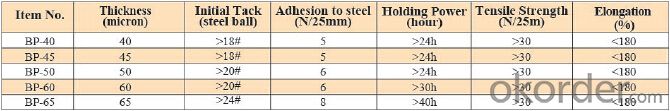

Typical Physical Reports of PVC Electrical Tape

Packaging

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1280mm; length according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Can packaging tape be used for sealing metal boxes?

- Yes, packaging tape can be used for sealing metal boxes. Packaging tape is designed to provide a secure and durable seal on various surfaces, including metal. It offers a strong adhesive that can effectively stick to metal surfaces, ensuring that the box remains sealed during transportation or storage. However, it is important to choose a packaging tape that is suitable for heavy-duty applications and can withstand the weight and pressure that may be exerted on the metal box. Additionally, it is recommended to clean the metal surface before applying the tape to ensure proper adhesion.

- Q: What materials are commonly used for packaging tape?

- The most commonly used materials for packaging tape are polypropylene, PVC, and paper.

- Q: Can packaging tape be used for sealing retail or product packaging?

- Yes, packaging tape can definitely be used for sealing retail or product packaging. Packaging tape is specifically designed for sealing boxes and packages, providing a secure and durable seal. It is commonly used in various industries, including retail, e-commerce, and product packaging. Packaging tape is typically made of strong adhesive material, ensuring that the package remains sealed during transportation and handling. It is easy to use, as it can be applied quickly and efficiently. Additionally, packaging tape is available in different sizes and strengths, allowing it to meet the specific needs and requirements of different types of retail or product packaging. Overall, packaging tape is a reliable and effective option for sealing retail or product packaging.

- Q: What are the alternatives to packaging tape?

- There are several alternatives to packaging tape that can be used for securing packages or boxes. Some of the popular alternatives include: 1. Duct Tape: Duct tape is a strong adhesive tape that can be used as an alternative to packaging tape. It is known for its durability and ability to stick to various surfaces. 2. Masking Tape: Masking tape is a type of adhesive tape that is less sticky compared to packaging tape. It is commonly used in painting or crafting projects, but can also be used to secure packages. 3. String or Twine: String or twine can be used to secure packages by wrapping it around the box and tying it securely. This method is often used for packages that do not require strong adhesion. 4. Packaging Straps: Packaging straps are commonly made of plastic or polyester and can be used to secure packages by strapping them tightly around the box. They provide a strong and secure alternative to packaging tape. 5. Adhesive Glue: Adhesive glue can be used as an alternative to packaging tape, particularly for small packages or envelopes. It is essential to choose a glue that is strong enough to securely seal the package. 6. Paper or Kraft Tape: Paper or kraft tape is a water-activated tape that is commonly used for sealing packages. It requires wetting the tape to activate the adhesive, providing a strong and secure seal. 7. Zip Ties: Zip ties are plastic ties that can be used to secure packages by fastening them tightly around the box. They are commonly used for securing large or heavy packages. When considering alternatives to packaging tape, it is important to assess the specific needs of the package, such as its size, weight, and handling requirements, to determine the most suitable option.

- Q: Is packaging tape resistant to chemicals or solvents?

- Yes, packaging tape is generally resistant to chemicals or solvents. Most packaging tapes are made from materials such as polypropylene or polyvinyl chloride (PVC) which have good chemical resistance properties. These materials are designed to withstand exposure to a wide range of chemicals and solvents commonly encountered in industrial or commercial environments. However, it is important to note that the specific resistance of packaging tape can vary depending on the brand, type, and quality of the tape. Therefore, it is always recommended to check the product specifications or consult the manufacturer for detailed information on the chemical resistance of a specific tape.

- Q: Can packaging tape be used for sealing moving boxes?

- Indeed, when it comes to sealing moving boxes, packaging tape proves to be quite useful. Its design is specifically tailored to secure boxes and packages during transit, boasting durability and strength that ensure a tight seal, preventing boxes from opening or items from spilling out. Moreover, its application is quick and effective, making it an easy-to-use option. It is worth noting that packaging tape often possesses resistance against moisture and can withstand diverse weather conditions, which makes it an ideal choice for long-distance moves or storage purposes. In summary, packaging tape is a dependable solution for sealing moving boxes and guaranteeing the safety of your belongings throughout the moving process.

- Q: Can packaging tape be used for sealing sports equipment or gear?

- Yes, packaging tape can be used for sealing sports equipment or gear. Packaging tape is designed to have strong adhesive properties, making it ideal for securing and sealing various items, including sports equipment. It can help keep equipment and gear securely fastened, preventing them from coming apart or getting damaged during transportation or storage. However, it's important to consider the specific needs and requirements of the sports equipment or gear being sealed, as some items may require more specialized tapes or sealing methods for optimal protection.

- Q: How do I prevent packaging tape from tearing during application?

- To prevent packaging tape from tearing during application, make sure to use a high-quality tape that is specifically designed for packaging. Additionally, ensure that the surface of the package is clean and dry before applying the tape. Avoid using excessive force while pulling the tape, instead apply it smoothly and evenly. If you're still experiencing tearing, you can try using a tape dispenser or moistening the tape slightly to make it more pliable.

- Q: What are the benefits of using reinforced packaging tape?

- Reinforced packaging tape offers numerous advantages. To begin with, it is specifically designed to provide greater strength and durability compared to regular tape. By incorporating a layer of robust fiberglass or nylon threads into the tape, it significantly enhances its resistance to tearing and breaking. This added strength makes it perfect for securely sealing heavy or bulky packages, guaranteeing their integrity during transportation or storage. Furthermore, reinforced packaging tape adds an extra layer of security to your shipments. The presence of reinforced fibers within the tape makes it much more challenging to tamper with or remove without detection. This serves as a deterrent against theft or unauthorized access, ensuring that your packages reach their destination safely and intact. Moreover, reinforced packaging tape boasts exceptional adhesive properties. It securely adheres to various surfaces, including cardboard, plastic, and other commonly used packaging materials. This strong adhesion ensures that the tape remains firmly in place and does not easily peel off, even under demanding conditions like extreme temperatures or rough handling during shipping. Additionally, reinforced packaging tape often possesses water-resistant or even waterproof qualities. This is particularly crucial when packages are exposed to moisture or unfavorable weather conditions. The tape's resistance to water helps shield the contents of your packages from potential damage caused by water or humidity. Lastly, the utilization of reinforced packaging tape can lead to cost savings and waste reduction. Its exceptional strength and durability allow you to use less tape to secure your packages, resulting in fewer tape rolls being used and less waste generated. Over time, this can lead to substantial cost savings and contribute to a more sustainable packaging process. In conclusion, the utilization of reinforced packaging tape offers a range of benefits, including increased strength, enhanced security, strong adhesion, water resistance, and potential cost savings. By investing in high-quality reinforced tape, you can ensure the reliable protection of your packages during transit, providing both you and your customers with peace of mind.

- Q: Is packaging tape safe to use on painted surfaces?

- Packaging tape is generally safe to use on painted surfaces, but there are a few factors to consider. Firstly, it is important to ensure that the paint is fully cured before applying any tape. This typically takes around 30 days, depending on the type of paint used. Applying tape to fresh or uncured paint can cause damage when the tape is removed. Secondly, the type of tape used can also make a difference. Most packaging tapes are designed to be easily removable without leaving residue or causing damage to surfaces. However, some low-quality tapes or tapes with strong adhesives may leave behind sticky residue or even peel off the paint when removed. It is recommended to use high-quality packaging tape that is specifically labeled as safe for painted surfaces. To be on the safe side, it is always a good idea to test the tape on a small, inconspicuous area of the painted surface before applying it extensively. This will help you ensure that the tape does not cause any damage or leave residue behind. If there are any concerns, it is advisable to consult the manufacturer's instructions or seek professional advice. Overall, when used properly and on fully cured paint, packaging tape should be safe to use on painted surfaces. However, it is important to exercise caution and choose the right tape to prevent any potential damage.

Send your message to us

3M Shipping Packaging Tape - BOPP Tape Water Based Acrylic Clear Transparent

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords