Duty Shipping Packaging Tape - Aluminum Foil Tape Synthetic Rubber Based 30micron

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

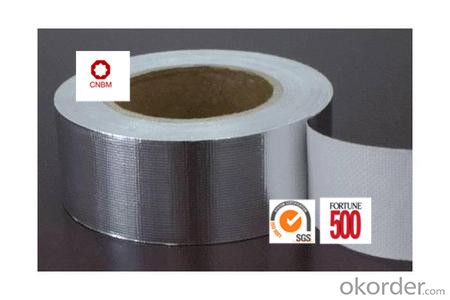

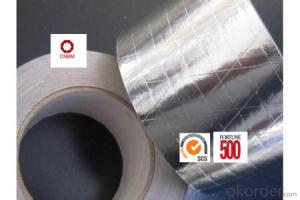

Synthetic Rubber Based Aluminum Foil Tape is of aluminum foil as the carrier, coating with solvent based acrylic, synthetic rubber-resin, or water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Synthetic Rubber Based Aluminum Foil Tape: widely used for seaming and jointing bonding of various vapor barriers, fixing thermal fin in refrigerators. Provide fast and permanent bond performance for vapor barrier against the moisture.

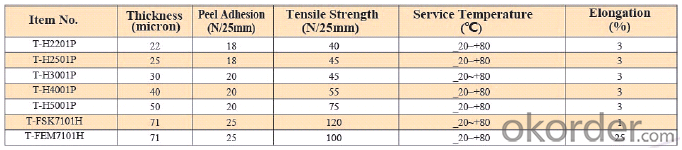

Typical Physical Reports of Synthetic Rubber Based Aluminum Foil Tape:

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1200mm; length according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Aluminum Foil Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Can scotch tape wrap wires?

- No, it's not safe. We should use electrical tape. We have a lot of transparent tapes for the last time

- Q: How do you remove packaging tape without leaving residue?

- To remove packaging tape without leaving residue, you can try using a hairdryer to gently heat the tape. This will help loosen the adhesive, making it easier to peel off without leaving any sticky residue behind. Additionally, using a rubbing alcohol or vinegar solution can help dissolve any stubborn residue that may be left behind. Just apply the solution to a cloth and gently rub the area until the residue is gone.

- Q: Can packaging tape be used for sealing glass bottles?

- Yes, packaging tape can be used for sealing glass bottles. However, it is important to note that it may not provide the same level of security and protection as specialized bottle sealing methods such as corking or using bottle caps. Packaging tape may not be as effective in preventing leakage or maintaining the freshness of the contents.

- Q: Selection of tapes

- So how do you choose the tape? In fact, the adhesive tape in the use of good and bad there are two criteria, one is the initial viscosity, one is to maintain the force, the two are inversely proportional. Under normal circumstances, adhesive force less than 10 adhesive tape is glue coated, teach less, usually only about 20 microns, such as stationery, tape, ordinary promotion belt used adhesive tape. The initial adhesive force of the normal sealing tape is between 15-20. The thickness of the adhesive tape is 22-28 microns. Is the standard thickness. But the tape on the market are mostly mixed with impurities, so the increase of the thickness of shielding impurities, the glue is also mixed with the toner, so transparent tape appeared egg yellow, light green, this tape is generally inferior.

- Q: Does packaging tape have a specific shelf life?

- Indeed, there is a designated lifespan for packaging tape. The duration of this lifespan fluctuates depending on the type and caliber of the tape. In general, the majority of packaging tapes possess a shelf life spanning from one to two years. Nevertheless, this lifespan can be elongated or abbreviated due to certain factors such as storage circumstances and exposure to sunlight or extreme temperatures. It is crucial to consult the manufacturer's guidelines or packaging for any explicit instructions regarding the tape's shelf life. To guarantee optimal performance and adhesive potency, it is advisable to employ packaging tape within its designated shelf life.

- Q: Can packaging tape be used for sealing office supplies or stationery?

- Certainly, office supplies or stationery can be sealed using packaging tape. This adhesive tape is highly versatile and frequently employed for sealing packages and boxes. Yet, it is crucial to take into account the size and weight of the item when using packaging tape for sealing smaller objects like office supplies or stationery. If the item is lightweight and the packaging tape is not excessively wide or bulky, it can serve as a convenient and effective option for sealing. Nevertheless, for smaller items, it might be more appropriate to utilize alternative types of tape, such as clear tape or double-sided tape, which are specifically designed for sealing stationery and office supplies.

- Q: Is packaging tape safe for use on leather or fabric items?

- Packaging tape is not recommended for use on leather or fabric items. While it may temporarily adhere to these surfaces, it can cause damage or leave adhesive residue when removed. It's best to use specific tapes or adhesive products designed for leather or fabric to ensure their safety and preservation.

- Q: How do I prevent packaging tape from becoming too sticky?

- To prevent packaging tape from becoming too sticky, there are a few measures you can take: 1. Store tape in a cool and dry place: Heat and humidity can often cause the adhesive on packaging tape to become stickier. Ensure that you store the tape in a cool and dry environment to maintain its proper consistency. 2. Avoid contact with dust and debris: Dust and debris can stick to the adhesive side of the tape, increasing its stickiness. Keep the tape away from dusty surfaces and make sure the areas where you will apply the tape are clean and free from any loose particles. 3. Use a tape dispenser: A tape dispenser can help regulate the amount of tape you apply and prevent excessive stickiness. It allows for a more controlled application and ensures you don't use more tape than necessary. 4. Don't stretch the tape excessively: Stretching the tape too much while applying it can cause it to become stickier. Apply the tape smoothly without pulling or stretching it excessively, as this can activate the adhesive further. 5. Consider using low-tack or removable tape: If you consistently face issues with sticky packaging tape, you can opt for low-tack or removable tape. These types of tape have less aggressive adhesive properties and are easier to remove without leaving sticky residue. By following these tips, you can maintain the desired level of stickiness on your packaging tape and make your packaging process more efficient.

- Q: Can packaging tape be used for sealing glass bottles?

- Indeed, glass bottles can be sealed using packaging tape. Nevertheless, it is crucial to acknowledge that packaging tape is not explicitly crafted for the purpose of sealing glass bottles; hence, it may not offer the equivalent level of robustness and air-tightness as dedicated bottle sealing techniques. Moreover, the adhesive on packaging tape may fail to adhere effectively to glass surfaces, potentially resulting in leakage or breakage. To guarantee optimal outcomes, it is advisable to employ appropriate bottle sealing methods like cork stoppers, screw caps, or specialized bottle sealing tapes specifically designed for glass bottles.

- Q: How wide is standard packaging tape?

- Standard packaging tape is typically 2 inches wide.

Send your message to us

Duty Shipping Packaging Tape - Aluminum Foil Tape Synthetic Rubber Based 30micron

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches