Packaging Supplier Tape - BOPP Adhesive Tape for Packing with Water Based Acrylic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

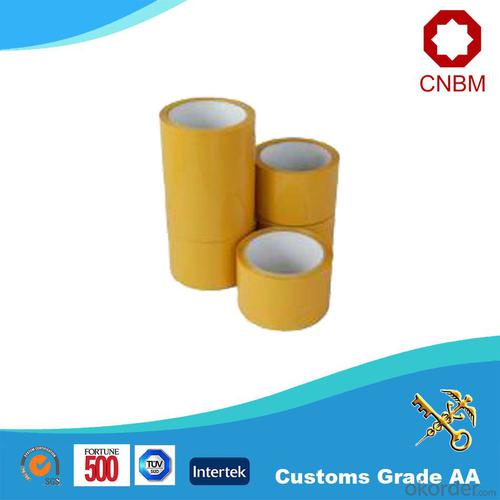

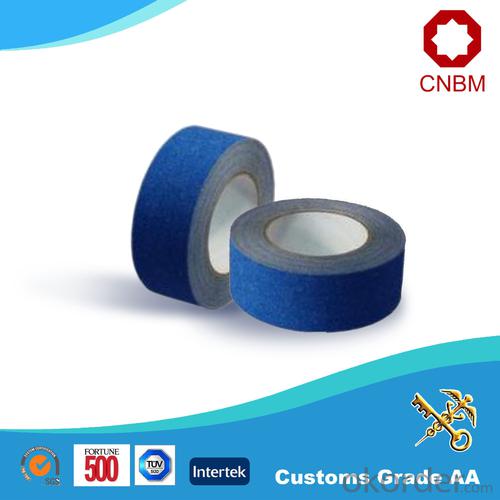

Bopp Adhesive Tape for Packing with Water Based Acrylic

1. Structure of Bopp Tape Description

Bopp Tape is of Bopp film as the carrier, coating with water based acrylic adhesive. It is widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

2. Main Features of Bopp Tape

Excellent in adhesion and flame retardant

Resistance to cold, heat and aging.

High Temperature stability

High mechanical strength and good impact resistance

Ideal for use in dispensers

Printable

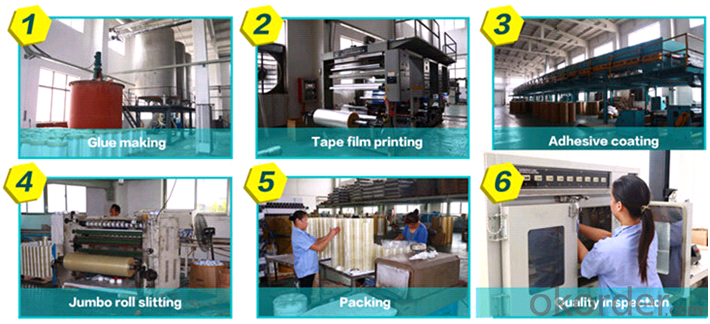

3. Bopp Tape Images

4. Bopp Tape Specification

| Standard size | 48mm*66m, 50mm*50m, 1.28m*4000m, etc |

| Thickness (micron) | 40 |

| Color | All Color Available |

| Initial Tack (steel ball) | >18# |

| Adhesion to steel (N/cm) | 5 |

| Holding Power (hour) | >24h |

| Tensile Strength (N/cm) | >30 |

| Elongation | <180 |

| Delivery | With 10-25days after receiving deposit |

| Payment | T/T & LC |

5. FAQ

Q1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Q2. What can we do for you?

Professional consultation on your local market

Custom-made advices for your need

Free samples

Your inquiry will be replied within 12 hours.

24 hours service for you

Satisfactory sales service

Q3. Delivery time

7-25 days after receiving the deposit

- Q: Can packaging tape be used for sealing plastic clamshell packaging?

- Yes, packaging tape can be used for sealing plastic clamshell packaging. Packaging tape is designed to securely seal various types of packaging materials, including plastic clamshell packaging. It provides a strong adhesive bond that holds the clamshell packaging together and prevents it from opening during shipping or handling. Additionally, packaging tape is durable and tear-resistant, ensuring that the clamshell packaging remains sealed and protected throughout the entire distribution process.

- Q: Is packaging tape safe to use on plastic hangers?

- Yes, packaging tape is generally safe to use on plastic hangers. It adheres well to most surfaces, including plastic, and provides a secure hold. However, it is recommended to use a moderate amount of tape to avoid damaging or leaving residue on the hangers.

- Q: Can packaging tape be recycled?

- Packaging tape can indeed be recycled, but its recyclability depends on the type of tape and the recycling facilities in your area. The commonly used clear or brown polypropylene tape, for example, cannot be recycled along with regular paper or plastic waste. However, certain recycling centers do accept specific types of tapes for recycling, such as those made from paper or with water-based adhesives. It's crucial to contact your local recycling center to determine their policy on packaging tape recycling and any specific requirements they may have. Furthermore, taking the tape off cardboard boxes before recycling them can enhance the recycling process. If recycling is not feasible, it is recommended to either reuse the packaging tape or dispose of it properly in the regular trash.

- Q: How does packaging tape perform on fabric or textile surfaces?

- Packaging tape typically does not perform well on fabric or textile surfaces. While it may adhere temporarily, it does not provide a strong bond on these materials and is not designed to withstand the flexibility and movement of fabrics. Additionally, the adhesive on packaging tape may leave residue on the fabric or even damage it when removed. Therefore, it is not recommended to use packaging tape on fabric or textile surfaces. Instead, it is advisable to use specialized fabric tapes or sewing techniques for any applications involving fabrics.

- Q: Can packaging tape be used for securing pallet loads?

- Yes, packaging tape can be used for securing pallet loads. It is commonly used to reinforce and stabilize palletized goods by securing them together, preventing shifting or toppling during transportation or storage.

- Q: What's the ingredient of 610#3m tape?

- Oil throwing test method:1. Objective: To evaluate the adhesion of paint coatings in products.2. scope: the product has injection / pad / foil / silk screen.3. equipment: 3M610 tape, knife4. program:4.1 before the test, make sure the paint coating surface is completely dry

- Q: Does packaging tape come in different colors for organization purposes?

- Indeed, packaging tape is available in a range of colors to aid in organization. Numerous companies provide packaging tape in diverse hues like red, blue, green, yellow, and black. These distinct colors can be utilized to classify and arrange assorted package types or to distinguish between shipments bound for various locations. They prove particularly advantageous in warehouses or shipping departments where numerous packages necessitate effortless identification and sorting. Furthermore, colored packaging tape can serve decorative functions, such as embellishing gift wrapping or crafting visually captivating packaging for retail merchandise.

- Q: Is packaging tape resistant to extreme pressure or weight?

- The purpose of packaging tape is to secure packages with a strong and reliable seal. However, the ability of the tape to withstand extreme pressure or weight can differ depending on its type and quality. Typically, packaging tapes are crafted from resilient materials such as polypropylene or polyester, enabling them to endure typical handling and transportation pressures. Nevertheless, it should be noted that packaging tape might not withstand excessively heavy loads or excessive pressure. In such instances, it is suggested to enhance the tape's strength by adding extra layers or employing heavy-duty tapes that are explicitly designed for high-pressure or weight-bearing purposes.

- Q: What are the considerations for using packaging tape on glossy surfaces?

- When using packaging tape on glossy surfaces, there are a few considerations to keep in mind. Firstly, the adhesive on the tape may not adhere as effectively to glossy surfaces compared to matte or rough surfaces. Therefore, it is important to ensure that the surface is clean and free of any dust, oil, or moisture that could hinder the tape's adhesion. Additionally, it is recommended to apply the tape firmly and evenly, exerting pressure to ensure proper contact. Lastly, it is advisable to test a small area first to assess the tape's adhesion and potential damage to the glossy surface, as some tapes may leave residue or could potentially damage the surface upon removal.

- Q: How does packaging tape perform in high-pressure conditions?

- Packaging tape is designed to reliably adhere and seal in various conditions, including high-pressure environments. When faced with high-pressure conditions like shipping or transportation, packaging tape excels due to its powerful adhesive properties and robust construction. Typically, pressure-sensitive adhesive (PSA) is used in packaging tape, allowing it to stick to surfaces when pressure is applied. This enables the tape to form a secure bond with the packaging material, even under high-pressure circumstances. The tape's adhesive strength guarantees that it remains firmly attached to the package, preventing any potential damage or tampering during transit. Furthermore, packaging tape is often crafted from sturdy materials such as polypropylene or PVC, further enhancing its performance in high-pressure situations. These materials possess exceptional tensile strength, enabling them to endure significant pressure without breaking or tearing. As a result, the tape maintains its integrity and keeps the package sealed and safeguarded. Moreover, packaging tape frequently exhibits resistance against moisture, temperature fluctuations, and other environmental factors that can impact its performance. This resistance ensures that the tape sustains its adhesive strength and structural integrity, even in demanding conditions like high-pressure environments. In summary, packaging tape is specifically engineered to excel in high-pressure conditions. Its potent adhesive properties, durable materials, and resistance to various environmental factors make it a dependable choice for preserving package integrity and protection during shipping or transportation.

Send your message to us

Packaging Supplier Tape - BOPP Adhesive Tape for Packing with Water Based Acrylic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches