Branded Packaging Tape South Africa - Bag Sealing Tape Jumbo Roll

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days/20' roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

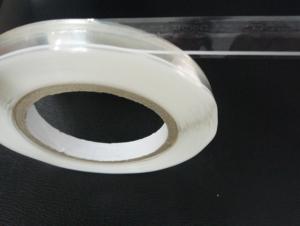

Genearal Information of bag sealing tape jumbo roll

Suitable for sealing plastic bags such as OPP or PP .PE materials.

Reusable, no peel off of adhesive, no residue.

It does not react chemically with the contents of the bags to color changes etc.

Name Bag Sealing Tape

Technical Data of bag sealing tape jumbo roll

Item No BG-16

Carrier PET film

Release Liner PE Film

Adhesive Acrylic Adhesive

Release Liner width 13/14mm

Carrier Width 6mm

AB Side Coating Width 4mm/6mm (left/right glue)

Remarks of bag sealing tape jumbo roll

The data above are typical results and subject to change without notice.

Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

The products should be stored at room temperature and be kept away wet and/or heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

- Q: Can packaging tape be used for repairing torn paper?

- No, packaging tape is not suitable for repairing torn paper. It is designed for sealing and securing packages, not for mending torn paper.

- Q: Does packaging tape come in different thicknesses?

- Indeed, various thicknesses can be found when it comes to packaging tape. One can find packaging tape in a range of thicknesses, which caters to diverse needs and demands. Heavier-duty tasks that necessitate extra durability and resilience usually call for thicker tapes. Conversely, thinner tapes are commonly utilized for lighter parcels or regular daily applications. The decision regarding the thickness depends on factors such as the weight and dimensions of the package in question, as well as the desired level of fortification.

- Q: Is packaging tape resistant to mold or mildew?

- Yes, packaging tape is generally resistant to mold or mildew.

- Q: Is packaging tape flammable?

- Yes, packaging tape is typically made from materials such as polypropylene or polyester, which are not highly flammable. However, it is important to note that some packaging tapes may have adhesive properties that contain flammable components. It is always best to refer to the specific packaging tape's safety data sheet or consult the manufacturer for accurate information regarding flammability.

- Q: Is packaging tape resistant to UV rays?

- Yes, packaging tape is generally resistant to UV rays. Most packaging tapes are made from materials like polypropylene or polyethylene, which have inherent resistance to UV radiation. This means that the tape can withstand exposure to sunlight and other sources of UV rays without deteriorating or losing its adhesive properties. However, it is important to note that prolonged exposure to UV rays can still cause some degradation over time. To ensure maximum longevity, it is recommended to store and use packaging tape in a cool, dry place away from direct sunlight whenever possible.

- Q: Does packaging tape come in different widths for different applications?

- Yes, packaging tape does come in different widths for different applications. Packaging tape is available in various widths ranging from as small as 0.75 inches to as wide as 3 inches or even more. The choice of width depends on the specific application and the size of the package being sealed. Smaller widths are often used for lighter weight packages or for sealing small boxes or envelopes. On the other hand, wider widths are commonly used for heavy-duty or larger boxes that require extra strength and security. The availability of different widths allows users to select the most appropriate tape size based on their specific packaging needs.

- Q: Can packaging tape be used for sealing plastic pet carriers?

- Yes, packaging tape can be used for sealing plastic pet carriers.

- Q: Can packaging tape be used for sealing cardboard boxes?

- Yes, packaging tape is commonly used for sealing cardboard boxes as it provides a strong and secure bond.

- Q: Can packaging tape be used for sealing packages with perishable items?

- No, packaging tape is not suitable for sealing packages with perishable items as it does not provide the necessary insulation or protection needed to maintain the freshness and quality of such items. It is recommended to use specialized packaging materials such as insulated boxes or coolers along with appropriate sealing methods for perishable items.

- Q: Can packaging tape be used for sealing storage containers?

- Packaging tape is an ideal choice for sealing storage containers. Its design focuses on delivering a strong and secure seal for a variety of materials, including storage containers. The packaging and shipping industries frequently rely on it to seal boxes, cartons, and other containers. Thanks to its robust adhesive, packaging tape can withstand the challenges of storage and transportation, guaranteeing the safety and protection of container contents. Moreover, its application is effortless, and it offers a dependable seal that effectively keeps dust, dirt, and moisture from infiltrating the storage container. Hence, utilizing packaging tape for sealing storage containers proves to be a practical and efficient solution.

1. Manufacturer Overview

| Location | Zhengzhou, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 2 Million |

| Main Markets | 20.00% Southeast Asia 20.00% South America 10.00% Eastern Europe 10.00% North America 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 19% - 22% |

| No.of Employees in Trade Department | 20-50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Branded Packaging Tape South Africa - Bag Sealing Tape Jumbo Roll

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days/20' roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords