Best Quality Crepe Paper Tape Colorful Tape Wholesale Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 5000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Crepe Paper Tape Colorful Tape Wholesale Tape

1. Description of Crepe Paper Tape

1.Carrier: Crepe Paper

2.Adhesive: Rubber

3.Standard Size: 24mm*30m,48mm*30m,0.99m*1800m,1.22*1800m etc.

4.Color: According to your request

5.Application: Widely sed for paint masking,furniture,shoe material production,automobile painting,light duty packing etc.

2. Advantages of Crepe Paper Tape

1 ) Different temperature resistance with good adhesion.

2 ) High tensile strength, good resistance of damage,no residue, eco-friendly.

3 ) Printing logo on paper core and carton mark as customers' need

4 ) SGS, ISO,BV, CTI certificates approved

5)Professional teamwork for orders

6)No.365 on the 2012 Fortune Global 500

7) Professional manufacturer with 31 years experiences of adhesive tapes

Special size,color can be made according to customer's requirement

3. Application of Crepe Paper Tape

1) Used for normal masking, such as indoor painting, car painting, car decoration painting.

2) Used in electronic industry and electric appliances for fixing and protection purposes.

3) Mainly designed for ordinary wrapping ,craftwork, lightduty masking.

4) Furniture, appliance automobile /shoes spray painting, color making, decoration and labels.

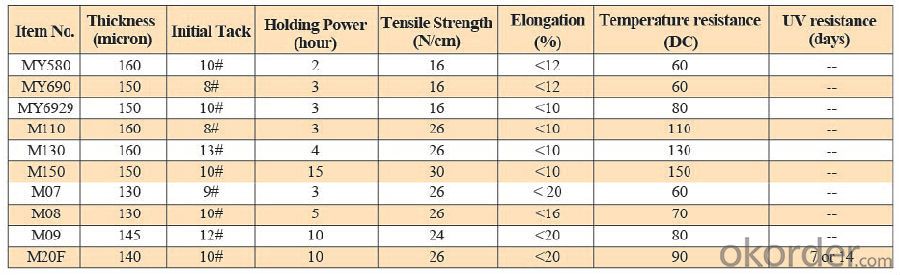

4. Details of Crepe Paper Tape

Material | Imported crepe paper coated with natural solvent rubber adhesives. |

Used | Widely used in the baking process in automobile industry, hardware industry |

Printing | Offer printing |

Color | Red, milky, green, white , yellowish, blue, black, or at will. |

Packaging | 6rolls/shrink,12rolls/shrink,72rolls/ctn,144rolls/ctn. |

MOQ | 20ft container or as you need. |

Payment terms | 30% in advance,70% balance the copy of B/L. |

Delivery time | 15workdays except the affirming date of logo on paper core and carton after receiving the deposit. |

Jumbo rolls size

| 1260mm*1800m, 1260mm*1000m |

Width | 3mm~1260mm normal width:12mm,18mm,24mm,36mm

|

Length | 10m~1800m normal length: 20m,33m,50m,100m |

Port | Shenzhen |

Certifications | ISO.9001.2008. and SGS. |

Certification:

- Q: Can packaging tape be used for sealing plastic tubing?

- Packaging tape has the capability to seal plastic tubing. Its design ensures a robust and reliable seal on different surfaces, including plastic materials. Nonetheless, it is crucial to take into account the particular purpose and demands of the plastic tubing. In instances where the tubing is intended for containing pressurized liquids or gases, or if it necessitates a long-lasting and resilient seal, specialized techniques like heat sealing or specific adhesives formulated for plastic materials might be more suitable. Ultimately, the appropriateness of packaging tape for sealing plastic tubing relies on the specific situation and requirements of the application.

- Q: How does packaging tape adhere to surfaces?

- Packaging tape sticks to surfaces by utilizing adhesive materials that are typically made from synthetic rubber or acrylic-based substances. These materials are specifically engineered to possess a strong bonding capability with a variety of surfaces, including cardboard, plastic, and metal. The adhesive on packaging tape functions by establishing a connection between the tape and the applied surface. When pressure is exerted on the tape, the adhesive substance spreads out and establishes contact with the surface. This contact enables the adhesive to interact with the molecules of the surface, resulting in the formation of a bond through intermolecular forces. The most commonly employed type of adhesive found on packaging tape is known as pressure-sensitive adhesive (PSA). PSA is specifically formulated to adhere to surfaces with minimal pressure. Upon the application of pressure, the adhesive substance flows and conforms to the surface, ultimately creating a robust bond. Furthermore, the adhesive on packaging tape is designed to withstand various environmental factors such as temperature, humidity, and moisture. This ensures that the tape remains firmly adhered to the surface, even in challenging conditions. In conclusion, packaging tape adheres to surfaces by utilizing adhesive materials, typically synthetic rubber or acrylic-based. These adhesives establish a bond between the tape and the surface through intermolecular forces, allowing the tape to securely stick.

- Q: Can packaging tape be used for sealing paper bags?

- Yes, packaging tape can be used for sealing paper bags.

- Q: Can packaging tape be used for heavy boxes?

- Yes, packaging tape can be used for heavy boxes. It is designed to provide strong adhesion and secure heavy and bulky packages during transit.

- Q: What is the best way to apply packaging tape?

- The best way to apply packaging tape is to first ensure that the surface is clean and dry. Start by holding the tape dispenser at a slight angle and pressing firmly on the surface, moving the dispenser smoothly in a straight line. Avoid stretching or folding the tape as it can weaken its adhesive properties. Finally, use a sharp object to cut the tape cleanly, ensuring a secure and professional seal.

- Q: How do you store unused rolls of packaging tape?

- In order to preserve the adhesive properties of unused rolls of packaging tape, it is crucial to store them in a cool and dry location. One possible option is to utilize a plastic storage bin or container equipped with a lid, as this will shield the tape from both moisture and dust. Another alternative is to employ a dedicated tape dispenser or a tape gun with a built-in storage compartment for extra rolls. This not only keeps the tape well-organized, but also prevents it from unraveling and becoming entangled. Remember to keep the rolls in an upright position to prevent any potential damage or deformation. By correctly storing unused rolls of packaging tape, you can guarantee that they will remain in optimal condition and readily available for use when necessary.

- Q: Can packaging tape be used for sealing automotive parts or equipment?

- Sealing automotive parts or equipment with packaging tape is generally not recommended. Packaging tape is designed for securely sealing lightweight materials like cardboard boxes, but it may lack the durability and adhesive strength necessary for automotive use. Automotive parts and equipment experience various conditions like heat, vibrations, and exposure to chemicals, which can degrade or weaken packaging tape over time. Furthermore, specialized sealing methods like gaskets, seals, or automotive-grade adhesives are typically required for proper functionality and long-lasting performance. Therefore, it is generally advisable to use sealing methods and materials specifically designed for automotive applications to ensure desired performance and reliability.

- Q: How do I prevent packaging tape from becoming brittle?

- In order to avoid packaging tape from becoming brittle, there are several steps that can be taken: 1. Proper storage is key. Ensure that the packaging tape is stored in a cool and dry location, away from direct sunlight. Extreme temperature fluctuations can lead to tape brittleness, so it is important to maintain a consistent environment to prolong its lifespan. 2. Excessive tension should be avoided when applying the tape. It is best not to stretch the tape too tightly or apply excessive pressure, as this can strain the adhesive and cause it to lose flexibility, resulting in brittleness. 3. Selecting the appropriate tape is essential. Different types of packaging tapes have varying levels of durability. Depending on your specific needs, choose a tape that is specifically designed for heavy-duty or long-term use. These tapes often have stronger adhesives and materials that are less prone to becoming brittle. 4. Handle the tape with care during use. It is important to handle the tape gently to avoid unnecessary stress. Pulling or tugging forcefully on the tape can weaken its structure and lead to brittleness. 5. Replace old tape when necessary. If you notice that your packaging tape has started to become brittle or lose its adhesive strength, it is best to replace it with fresh tape. Using old and brittle tape may compromise the security of your packaging, increasing the risk of it breaking or coming undone during transit. By following these preventive measures, you can help maintain the flexibility and durability of your packaging tape, ensuring it remains reliable for your packaging needs.

- Q: What are the benefits of using silent packaging tape?

- Using silent packaging tape offers several advantages. Firstly, it guarantees a noiseless packaging experience, which is especially valuable in settings that require silence, such as offices, libraries, or other tranquil spaces. By eliminating the loud noises typically associated with regular packaging tape, silent tape helps maintain a serene and peaceful atmosphere. Secondly, employees who regularly handle packaging tasks prefer silent packaging tape. The absence of noise during the taping process reduces the risk of stress or fatigue caused by noise, contributing to a more comfortable work environment. This, in turn, can lead to increased productivity and employee satisfaction. Furthermore, silent tape is an excellent choice for businesses that prioritize customer satisfaction. When packaging items for shipment, particularly delicate or fragile ones, using silent tape ensures a professional and refined appearance. The lack of loud noise during the packaging process also prevents any potential disturbance or annoyance to customers, both during the packaging phase and upon receiving their packages. In addition, silent packaging tape is often crafted with high-quality adhesive properties, providing a secure and long-lasting seal that keeps packages intact during transit. This reduces the chances of damaged goods and the associated costs of having to resend or replace items. Lastly, silent tape is frequently made from eco-friendly materials, making it advantageous for businesses aiming to minimize their environmental impact. By opting for silent packaging tape made from recyclable or biodegradable materials, companies can align their packaging practices with their sustainability goals. In conclusion, the benefits of using silent packaging tape include noise reduction, improved employee satisfaction and productivity, enhanced customer experience, secure sealing, and eco-friendliness. By choosing silent tape, businesses can create a more efficient, pleasant, and environmentally conscious packaging process.

- Q: Can packaging tape be used for packing fragile items?

- Yes, packaging tape can be used for packing fragile items. However, it is important to note that using only packaging tape may not provide sufficient protection for delicate or breakable objects. It is recommended to use additional packaging materials such as bubble wrap, foam peanuts, or corrugated cardboard to ensure proper cushioning and prevent damage during transit. The packaging tape can then be used to securely seal the package and reinforce the overall packaging.

Send your message to us

Best Quality Crepe Paper Tape Colorful Tape Wholesale Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 5000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords